Industrial Robotic Arm: Exploring the Benefits of a 7 Axis Robot

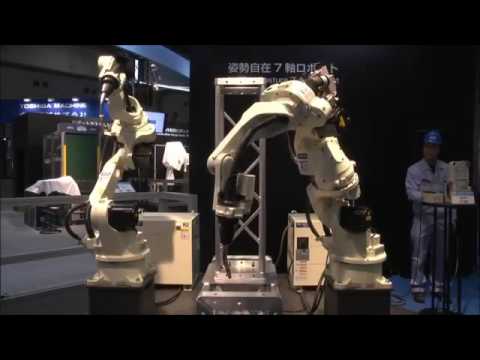

In the ever-evolving world of technology, the integration of robotics has played a significant role in enhancing productivity and efficiency in various industries. The advancements in industrial robotic arms have revolutionized manufacturing processes, allowing businesses to streamline their operations and stay competitive in the market. Recently, at the OTC Expo in Tokyo Convention Center, an intriguing comparison emerged between the capabilities of 6 and 7 axis robot arms. This article explores the advantages of using a 7 axis robot arm, shedding light on its uniqueness and its potential to transform the manufacturing landscape.

The use of industrial robotic arms has become increasingly prevalent in the manufacturing industry, thanks to their ability to perform complex tasks with precision and consistency. Traditionally, 6 axis robot arms have been the go-to choice for many businesses due to their versatility and cost-effectiveness. These robotic arms can efficiently perform tasks in three-dimensional space, offering solutions for a wide range of industrial applications. However, the emergence of the 7 axis robot arm has opened up a whole new realm of possibilities.

The distinguishing feature of the 7 axis robot arm lies in its additional axis of motion. This extra degree of freedom allows the arm to maneuver in a more dynamic and flexible manner. The additional axis enables the arm to tilt or rotate further, enhancing its reach and enabling it to perform intricate tasks with ease. This heightened flexibility is particularly advantageous in industries that require precise and intricate movements, such as the automotive, aerospace, and electronics sectors.

When it comes to industries that demand precision, the 7 axis robot arm truly shines. The added axis allows for greater dexterity, making it possible to perform tasks that were previously challenging for 6 axis arms. For instance, in the automotive industry, the 7 axis robot arm can effortlessly handle delicate and intricate tasks such as assembling engine components or welding together car frames. Its ability to precisely maneuver in tight spaces ensures a higher level of accuracy and reduces the need for human supervision. This translates into increased production speed and improved overall efficiency.

Furthermore, the 7 axis robot arm's enhanced range of motion streamlines production processes by reducing the need for repositioning or readjusting the arm during tasks. This not only saves time but also minimizes the risk of errors caused by human interference. By minimizing the need for manual intervention, businesses can ensure consistent and reliable output, leading to higher quality products and customer satisfaction.

The benefits of the 7 axis robot arm are not limited to increased flexibility and precision. This advanced technology also has a positive impact on overall cost-efficiency. Despite the initial investment required to acquire a 7 axis robot arm, the long-term gains are substantial. The arm's ability to handle intricate tasks efficiently reduces production time and minimizes wastage, resulting in reduced labor costs and increased productivity. Additionally, the improved precision and consistency provided by the 7 axis arm significantly lower the error rate, thereby reducing costs associated with product defects and rework.

In conclusion, the introduction of the 7 axis robot arm has revolutionized the manufacturing industry by offering unmatched flexibility, precision, and cost-efficiency. The OTC Expo in Tokyo Convention Center provided a valuable platform to witness the comparison between 6 and 7 axis robot arms, giving us insights into the advantages of the latter. The 7 axis robot arm's ability to perform intricate tasks with enhanced dexterity and efficiency has the potential to transform industrial processes in sectors such as automotive, aerospace, and electronics. With its extended reach and improved range of motion, the 7 axis robot arm opens up new possibilities for businesses to excel in an increasingly competitive market. Embracing this advanced technology could be the key to unlocking greater productivity, quality, and success in the manufacturing landscape.

Industrial Robot

"Unveiling the Distinctions: A Comprehensive Analysis of 6-axis vs. 7-axis Robot Arm Systems & Industrial Equivalents"