Stretch film machines, also known as pallet orbital stretch wrappers, play a crucial role in the packaging industry. These machines are extensively used for wrapping pallets of products with stretch film, providing stability and protection during transportation and storage. In this article, we will explore the key points about stretch film machines and delve into the benefits they offer.

Stretch film machines, such as the Pallet Orbital Stretch Wrapper, have revolutionized the way products are packaged. Gone are the days of tedious manual wrapping, as these machines automate the process, saving time and improving efficiency. With the ability to handle large volumes of products, they are an essential component of any modern packaging line.

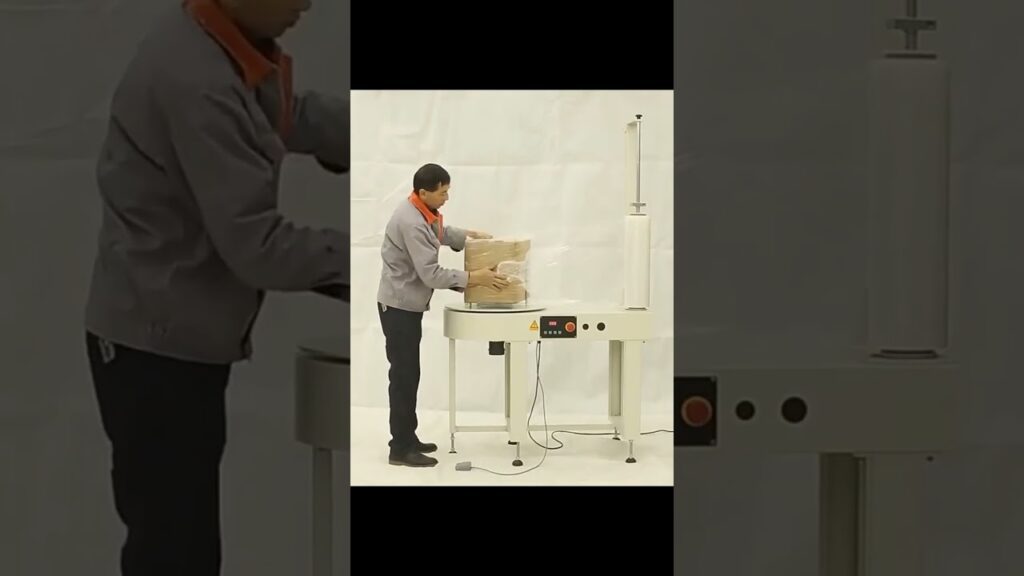

The primary purpose of a stretch film machine is pallet wrapping. It securely wraps a stretch film around the pallet, tightly securing the products and preventing them from shifting or toppling during transit. This not only minimizes the risk of damages but also ensures that the products remain intact, maintaining their quality and appearance. The stretch film acts as a protective shield, safeguarding the products from moisture, dust, and other external elements.

The Pallet Orbital Stretch Wrapper offers several advantages over traditional wrapping methods. Firstly, it ensures consistency in wrapping, achieving uniform tension throughout the pallet. This eliminates any weak points that may arise from human error, providing a secure and reliable wrap every time. Additionally, these machines can wrap pallets of various sizes and shapes, accommodating the diverse needs of different industries.

Another significant benefit of stretch film machines is the cost-saving potential they offer. By automating the wrapping process, companies can reduce labor expenses and increase productivity. The efficiency of these machines allows for faster operations, resulting in higher output. Moreover, the stretch film used in these machines is more cost-effective compared to other packaging materials, such as shrink wrap. It stretches to cover a larger surface area, reducing the amount of film required per pallet.

The Pallet Orbital Stretch Wrapper utilizes advanced technology to maximize efficiency and convenience. It features a user-friendly interface that allows operators to set specific parameters, such as wrap tension, number of revolutions, and speed. These customizable options ensure that the machine can be tailored to meet the specific requirements of different products and packaging standards.

In terms of maintenance, stretch film machines are designed for longevity and durability. Regular servicing and upkeep are essential to ensure their smooth operation. Manufacturers often provide detailed manuals and customer support to assist users in maintaining and troubleshooting any issues that may arise.

As the packaging industry continues to evolve, the demand for efficient and reliable stretch film machines is expected to rise. The automation and versatility offered by these machines make them an indispensable asset for businesses across various sectors. With the ability to streamline operations, reduce costs, and enhance product protection, the Pallet Orbital Stretch Wrapper is at the forefront of packaging technology.

In conclusion, stretch film machines, particularly the Pallet Orbital Stretch Wrapper, have revolutionized the packaging industry. These machines are extensively used for pallet wrapping, ensuring stability and protection during transportation and storage. With the ability to automate the wrapping process, they save time, increase efficiency, and reduce labor expenses. The stretch film provides a protective shield, safeguarding products from external elements. As technology advances, stretch film machines will continue to play a vital role in the packaging process, facilitating seamless operations and enhancing product integrity.

Orbital Stretch Wrapper

“Unveiling the Mechanics Behind Stretch Film Machine & Pallet Orbital Stretch Wrapper: Efficient Packaging Solutions Revealed!”