## Types of Industrial Robots: Exploring the Singularity in Six-Axis Arms

The world of robotics has witnessed significant advancements over the years, leading to the creation of various types of industrial robots. These robots have revolutionized industries by automating processes, improving efficiency, and increasing productivity. In this article, we will focus on the typical six-axis industrial robot arm and delve into the three types of robot singularity that can occur within it: wrist singularities, elbow singularities, and shoulder singularities.

To understand the concept of robot singularity, it is crucial to comprehend the structure of a six-axis industrial robot arm. This type of robotic arm consists of six joints or axes, each providing a different range of motion. These axes include three rotary axes (shoulder, elbow, and wrist) and three linear axes (X, Y, and Z). This complexity allows for a wide range of movements and positioning capabilities.

### What are robot singularities?

Robot singularities occur when the robotic arm reaches a joint configuration where it loses one or more degrees of freedom. In simpler terms, the arm becomes restricted in its movements and cannot achieve certain positions or orientations. Singularity points are particular joint configurations that lead to these limitations.

Now, let's explore the three types of robot singularity commonly encountered in six-axis industrial robot arms:

#### 1. Wrist Singularities

Wrist singularities arise when the robotic arm approaches certain joint configurations of the wrist axis. In these configurations, the robot arm loses the ability to rotate its wrist freely. Wrist singularities often occur when two axes of the wrist coincide, resulting in a loss of one degree of freedom. This restricts the arm from achieving certain positions or orientations, affecting its precision and flexibility.

#### 2. Elbow Singularities

Elbow singularities occur when the robot arm reaches specific joint configurations of the elbow axis. Similar to wrist singularities, elbow singularities limit the arm's motion by causing a loss of one degree of freedom. In this case, the arm cannot fully extend or contract, preventing it from reaching specific positions or orientations. Elbow singularities are typically encountered when two axes of the elbow joint align, leading to restricted mobility.

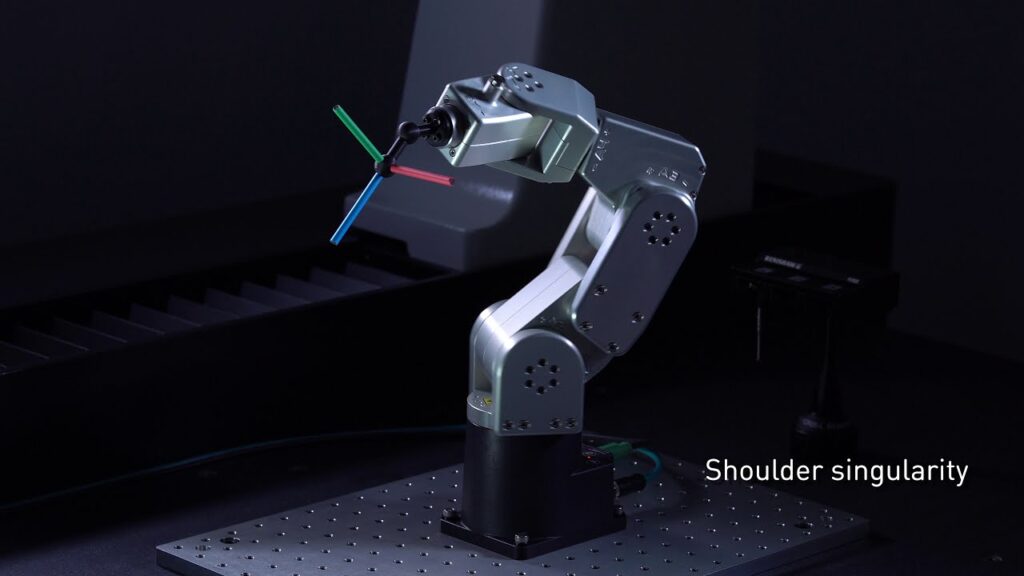

#### 3. Shoulder Singularities

Shoulder singularities arise when the robotic arm approaches particular joint configurations of the shoulder axis. These configurations result in a loss of one degree of freedom, restricting the arm's motion and limiting its ability to reach specific positions or orientations. Shoulder singularities often occur when two axes of the shoulder joint align, causing the arm to lose its full range of movement.

### The Impact on Industrial Applications

The presence of robot singularities in six-axis industrial robot arms calls for careful planning and optimization in various industrial applications. Let's explore how these singularities affect specific scenarios:

#### Assembly Line Operations

In assembly line operations, precise movements and positioning are crucial. Robot singularities can lead to inaccuracies or errors in the assembly process. Manufacturers must consider these singularities when programming the robots to ensure that they avoid such configurations and maintain consistent performance.

#### Material Handling

Efficient material handling requires a high degree of control and accuracy. Robot singularities can hinder the smooth transfer of materials or objects, leading to potential delays or disruptions in the workflow. By understanding and accounting for singularities, engineers can optimize the path planning and improve the overall efficiency of material handling tasks.

#### Welding Operations

Welding is a vital process in many industries, and precise control is paramount. Robot singularities can affect the path planning for welding operations, resulting in inconsistencies or defects. By utilizing advanced algorithms and software, engineers can minimize the impact of singularities and ensure precise, high-quality welds.

#### Painting and Coating Applications

In painting and coating applications, achieving uniform coverage is essential. Robot singularities can disrupt the smooth and even distribution of paint or coating materials, leading to inadequacies or uneven surfaces. By carefully analyzing the robot's range of motion and programming paths to avoid singularities, manufacturers can maintain consistent and flawless finishes.

### Conclusion

As we've explored the world of six-axis industrial robot arms, we've encountered the three types of robot singularity: wrist singularities, elbow singularities, and shoulder singularities. These singularities impose limitations on the arm's movement and require careful consideration and optimization in various industrial applications.

By understanding the concept of robot singularity and its impact, engineers and manufacturers can overcome these challenges and leverage the potential of industrial robots. Through advanced programming, path planning, and optimization techniques, the limitations imposed by singularities can be mitigated, leading to enhanced efficiency, precision, and productivity in industrial processes. The constant evolution of robotic technologies continues to push the boundaries of what these machines can achieve, propelling industries forward into a more automated and efficient future.

Industrial Robot

Understanding Robot Singularities and Exploring Various Types of Industrial Robots