Types of Industrial Robots

The field of robotics has seen significant advancements in recent years, with a wide range of industrial robots being developed to improve efficiency and productivity in various industries. These robots have revolutionized the way tasks are performed, making repetitive and dangerous tasks easier while increasing precision and accuracy. In this article, we will explore the different types of industrial robots and their applications.

One of the most common types of industrial robots is the articulated robot. These robots have a series of joints, similar to a human arm, which allows them to mimic human-like movements. Articulated robots are highly versatile and can be found in a wide range of applications such as welding, material handling, assembly, and painting. They are known for their ability to perform complex and precise tasks with multiple degrees of freedom.

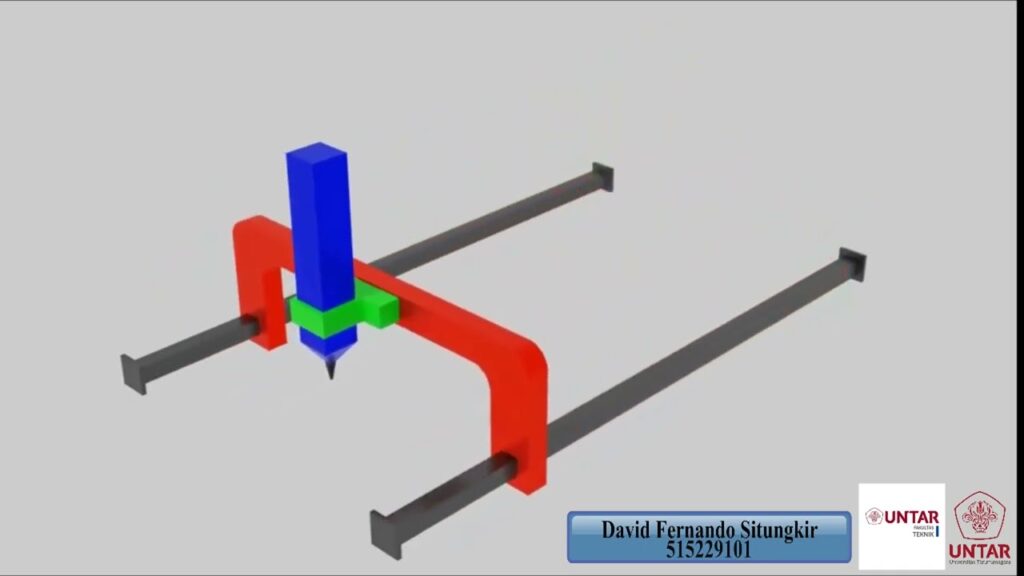

Another type of industrial robot is the Cartesian robot, also known as a gantry robot. These robots have a three-dimensional rectangular coordinate system that allows them to move along linear paths. Cartesian robots are commonly used in industries such as packaging, material transfer, and machine loading and unloading. They are known for their high speed, accuracy, and repeatability.

SCARA robots, which stands for Selective Compliance Assembly Robot Arm, are another popular type of industrial robot. These robots have a horizontal arm with several joints and are mainly used in applications that require fast and precise movements, such as assembly, pick and place, and inspection. SCARA robots are known for their speed, precision, and ability to work in confined spaces.

Delta robots, also known as parallel link robots, are specialized robots that excel in high-speed pick and place operations. These robots consist of several connected arms that are controlled by motors. Delta robots are commonly used in the food and beverage industry, as well as in electronics manufacturing, where high-speed and precise movements are essential.

Collaborative robots, or cobots, are a relatively new addition to the world of industrial robots. These robots are designed to work alongside humans, assisting them with various tasks. Cobots are equipped with a range of safety features, such as force sensors and vision systems, that allow them to interact with humans safely. They are highly flexible and can be easily programmed and reprogrammed to adapt to different tasks.

Industrial robots are also used in the field of healthcare. Surgical robots, such as the Da Vinci Surgical System, have gained popularity in recent years. These robots assist surgeons in performing minimally invasive surgeries with enhanced precision and control. They provide surgeons with a magnified, high-definition 3D view of the surgical site and allow for greater dexterity and flexibility during the procedure.

In conclusion, the field of robotics has witnessed remarkable advancements in the development of industrial robots. From articulated robots to collaborative robots, each type has its own unique characteristics and applications. These robots have revolutionized various industries, improving efficiency, productivity, and safety. As technology continues to evolve, we can expect even more innovative and sophisticated industrial robots to emerge, further enhancing the way tasks are performed in industries across the globe.

References:

– Types of Industrial Robots: https://www.youtube.com/watch?v=D9J3rvK-AI8

– Apa saja Type Industrial Robots? (Industrial Robot): https://www.youtube.com/watch?v=9mG1bgs_ND0

Industrial Robot

“Exploring the Different Types of Industrial Robots: A Comprehensive Overview”