Robots have long been at the forefront of technological advancements, revolutionizing processes across various industries. From simple repetitive tasks to complex operations, industrial robots have proven their efficiency and effectiveness in boosting productivity. However, there is a significant misconception when it comes to programming these machines. Many people believe that it only takes a few minutes to program an industrial robot, but the reality is far from that.

In a recent YouTube video titled “Only 5 Minutes for Programming? Are You Sure?”, the team at ABAGY ROBOTIC WELDING sheds light on the fundamental difference in safety between industrial robots and collaborative robots, also known as cobots. The video highlights the challenges in programming and operating industrial robots and how cobots offer a safer alternative.

Industrial robots are powerful, versatile machines used in various fields, including manufacturing, automotive assembly, and logistics. They are designed to perform repetitive and hazardous tasks with precision and speed. These robots are typically placed in cages or safety enclosures, segregated from human workers to ensure safety. Programming industrial robots requires extensive knowledge of programming languages, specific software, and complex algorithms.

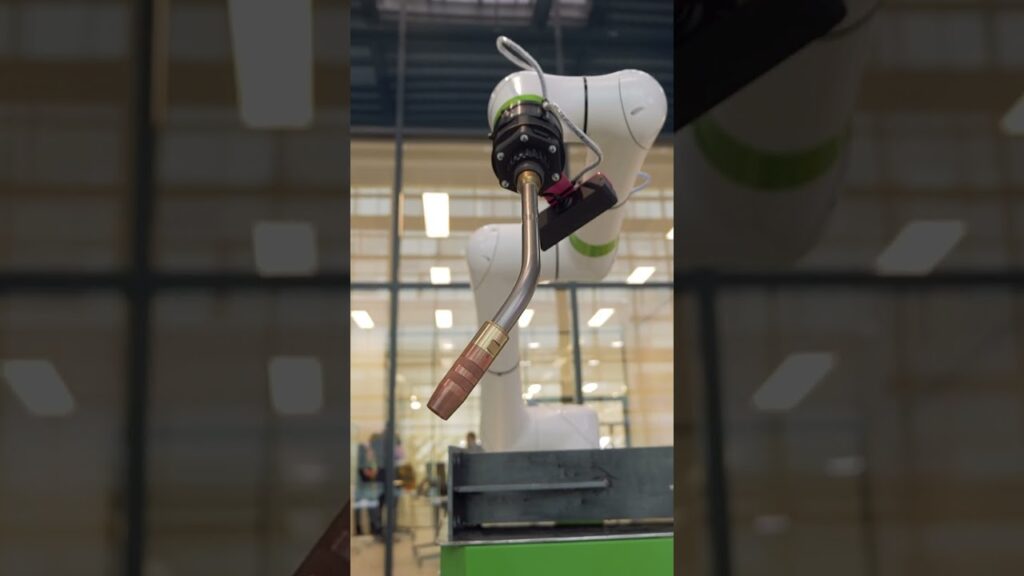

On the other hand, cobots are specifically designed to work alongside humans in a collaborative environment. Unlike their industrial counterparts, cobots prioritize safety and accessibility. They have built-in safety features such as sensors that can detect the presence of humans and halt their movements if necessary. This allows human operators to work side by side with cobots without the need for protective barriers or safety enclosures.

In the YouTube video, ABAGY ROBOTIC WELDING explains that programming cobots is comparatively easier and quicker than programming industrial robots. This is primarily due to their user-friendly interfaces and intuitive programming methods. Cobots utilize a combination of graphical interfaces and drag-and-drop programming, making it more accessible to individuals with non-technical backgrounds. This means that workers can be trained to program and operate cobots in a relatively short amount of time, thus increasing efficiency and adaptability in the workplace.

The video also highlights some of the potential applications of industrial robots and cobots. Industrial robots excel at tasks that require high precision and repeatability. For example, in the manufacturing industry, industrial robots are often deployed for assembly line tasks such as welding, painting, and packaging. They can perform these tasks consistently and with minimal errors, leading to increased productivity and reduced costs.

On the other hand, cobots find their niche in tasks that require human interaction and flexibility. In industries such as healthcare, cobots can assist healthcare professionals in tasks like patient care, medication delivery, and hospital logistics. Cobots can also be utilized in small-scale manufacturing or collaborative assembly tasks where human assistance and decision-making are essential.

The video’s message is clear: while industrial robots have their advantages, the perception that programming them can be done in minutes is misleading. Companies and workers need to be aware of the complexities involved in operating and programming industrial robots. On the other hand, cobots offer a safer and more accessible solution for collaborative work environments. With their user-friendly interfaces and intuitive programming methods, cobots bridge the gap between humans and robots, enabling task automation without compromising safety.

In conclusion, programming industrial robots is a complex process that requires specialized skills and knowledge. The video from ABAGY ROBOTIC WELDING highlights the fundamental difference in safety between industrial robots and cobots. While industrial robots excel in tasks that require precision and repeatability, programming them is a time-consuming and intricate process. On the other hand, cobots offer a safer alternative with their user-friendly interfaces and intuitive programming methods. As technological advancements continue to reshape industries, understanding the differences between industrial robots and cobots is crucial in optimizing productivity and ensuring workplace safety.

Industrial Robot

The Challenges of Programming Cobots: Simplifying ABAGY ROBOTIC WELDING and Industrial Robots Applications