Industrial Robotic Arm: Enhancing Efficiency and Precision in Manufacturing Processes

In the fast-paced world of manufacturing, efficiency and precision are key factors in ensuring productivity and the delivery of high-quality products. Over the years, the introduction of automation has revolutionized various industries, streamlining processes and reducing human errors. One such advancement in automation is the Industrial Robotic Arm, a powerful tool that has transformed the manufacturing landscape.

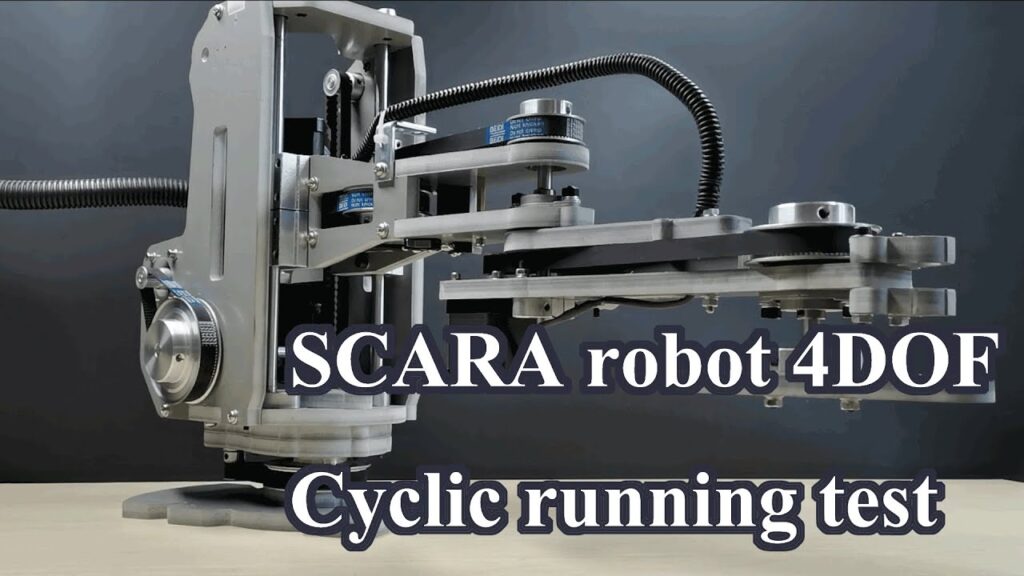

Recently, a fascinating video surfaced on YouTube showcasing the capabilities of the SCARA robot arm in a 4DOF Cyclic running test. This DIY CNC (Computer Numerical Control) project provided a glimpse into the impressive capabilities of these robotic arms.

The SCARA robot arm, also known as Selective Compliance Assembly Robot Arm, is a type of industrial robot arm widely used in various manufacturing applications. Its design allows for easy integration into existing production lines, making it a versatile and valuable asset for any manufacturing operation.

This specific test demonstrated the cyclic running capabilities of the SCARA robot arm, highlighting its ability to consistently perform tasks with speed and precision. The video showcased the arm moving swiftly, picking up objects, and precisely placing them at designated locations. The fluidity of its movements and the accuracy in which it completed tasks were truly remarkable.

What makes the Industrial Robotic Arm so valuable in manufacturing processes? Let us delve deeper into its features and functionalities:

1. Precision: The SCARA robot arm's precise movement control and repeatability make it ideal for tasks that require accurate positioning and assembly. This level of precision reduces errors and improves overall product quality.

2. High Speed: Time is of the essence in manufacturing, and the SCARA robot arm delivers on that front. With its rapid movement capabilities and quick reaction times, it can significantly increase production speed and efficiency.

3. Programming Flexibility: These robotic arms can be easily programmed and reprogrammed to perform different tasks or adapt to changes in the production line. This flexibility ensures that manufacturers can quickly respond to evolving production demands.

4. Enhanced Safety: Industrial Robotic Arms are designed with safety in mind. By automating repetitive and potentially hazardous tasks, they minimize the risk of workplace accidents. This not only protects employees but also reduces downtime and associated costs.

5. Cost-Effectiveness: While implementing automation may require an initial investment, the long-term benefits outweigh the costs. Industrial Robotic Arms can operate non-stop, reducing labor costs and increasing production capacity without compromising quality.

The video provided not only a glimpse into the capabilities of the SCARA robot arm but also ignited thoughts on the future of automation in manufacturing. With advancements in artificial intelligence and machine learning, we can expect even more sophisticated robotic arms that can learn and adapt to complex tasks. The integration of sensors and real-time data analysis will further enhance their performance, making them invaluable assets in the manufacturing industry.

Industrial Robotic Arms have already made a significant impact in various industries, from automotive manufacturing to electronics assembly. As technology continues to advance, we can foresee them playing an even larger role in areas such as medical device manufacturing, food processing, and pharmaceutical production. The ability to automate intricate and delicate processes in these sectors will not only improve efficiency but also ensure product quality and safety.

In conclusion, the SCARA robot arm 4DOF Cyclic running test showcased in the YouTube video is just a glimpse into the vast potential of the Industrial Robotic Arm. Its precision, speed, flexibility, safety features, and cost-effectiveness make it a game-changer in the manufacturing industry. As we move towards a more automated future, embracing these technological advancements will undoubtedly lead to increased productivity, enhanced quality, and ultimately, improved overall manufacturing processes.

Industrial Robot

"Efficient Cyclic Running Test of a 4DOF SCARA Robot Arm | Robotic Arm Crafting Tutorial with CNC and Industrial Applications"