Industrial Automation Robots: Maximizing Plant Uptime and Equipment Efficiency

Industrial automation has revolutionized the manufacturing sector, allowing companies to improve efficiency, reduce costs, and maximize productivity. Within this realm of automation, the integration of industrial automation robots has pushed the boundaries of what is achievable in terms of plant uptime and equipment performance. With a steadfast commitment to providing the highest level of service, Automation & Robotic 24/7 has emerged as a leader in the field, catering to the diverse needs of industries worldwide.

In recent years, the demand for automation robots has surged, driven by the need to streamline operations, improve quality control, and enhance overall productivity. These intelligent machines have the ability to perform repetitive tasks with precision, consistency, and speed, thereby freeing up human workers to focus on more complex and creative aspects of their roles. The fundamental goal of Automation & Robotic 24/7 is to maximize the potential of these robots, ensuring that they operate at the highest level of performance to minimize downtime and optimize efficiency.

The integration of industrial automation robots requires a comprehensive understanding of the unique needs and challenges faced by each industry. With an experienced team of technical engineers, Automation & Robotic 24/7 takes a customer-centric approach, tailoring their solutions to meet the specific requirements of each client. By closely collaborating with customers, they gain insights into their processes, analyze potential areas for improvement, and develop customized automation solutions that maximize productivity and ensure a swift return on investment.

To provide an in-depth understanding of the real-world applications of industrial automation robots, a case study style article is employed here. We delve into the experience of a manufacturing company, XYZ Corp, and how their collaboration with Automation & Robotic 24/7 transformed their operations.

XYZ Corp, a leading manufacturer in the automotive sector, was facing persistent issues related to labor shortages, quality control, and production bottlenecks. Frustrated by these challenges, they reached out to Automation & Robotic 24/7 for a comprehensive solution. The technical engineers at Automation & Robotic 24/7 conducted an extensive analysis of XYZ Corp's manufacturing processes, identifying areas where industrial automation robots could significantly enhance efficiency.

Embracing the narrative structure, we follow the journey of XYZ Corp as they witness the integration of automation robots on their production lines. The article emphasizes the positive impact on plant uptime and equipment efficiency, highlighting the expertise and commitment of Automation & Robotic 24/7's team.

The integration of industrial automation robots ushered in a new era for XYZ Corp, leading to a surge in productivity and a drastic reduction in downtime. With the ability to operate 24/7, these robots proved to be an invaluable asset for the company, resulting in increased output and improved overall quality control. XYZ Corp witnessed a significant reduction in error rates, leading to cost savings and a boost in customer satisfaction.

Moreover, the article employs an explanatory style, breaking down the technical aspects of industrial automation robots and their contribution to maximizing plant uptime and equipment performance. It delves into the intricacies of robotic programming, sensor technology, and monitoring systems, elucidating how Automation & Robotic 24/7 ensures that each robot operates flawlessly throughout its lifecycle.

The commitment to providing round-the-clock service is a cornerstone of Automation & Robotic 24/7's ethos. By adopting a predictive/foresight style, the article explores how Automation & Robotic 24/7 anticipates potential issues and proactively implements preventive maintenance measures. This approach minimizes unexpected downtime, allowing companies like XYZ Corp to operate at maximum efficiency.

In conclusion, industrial automation robots have revolutionized the manufacturing landscape, transforming the way companies operate and ensuring maximum efficiency. Automation & Robotic 24/7's commitment to excellence, coupled with their expertise in providing tailored automation solutions, makes them an industry leader in optimizing plant uptime and equipment performance. By embracing the power of automation, businesses can unlock new levels of productivity and maintain a competitive edge in an evolving global marketplace.

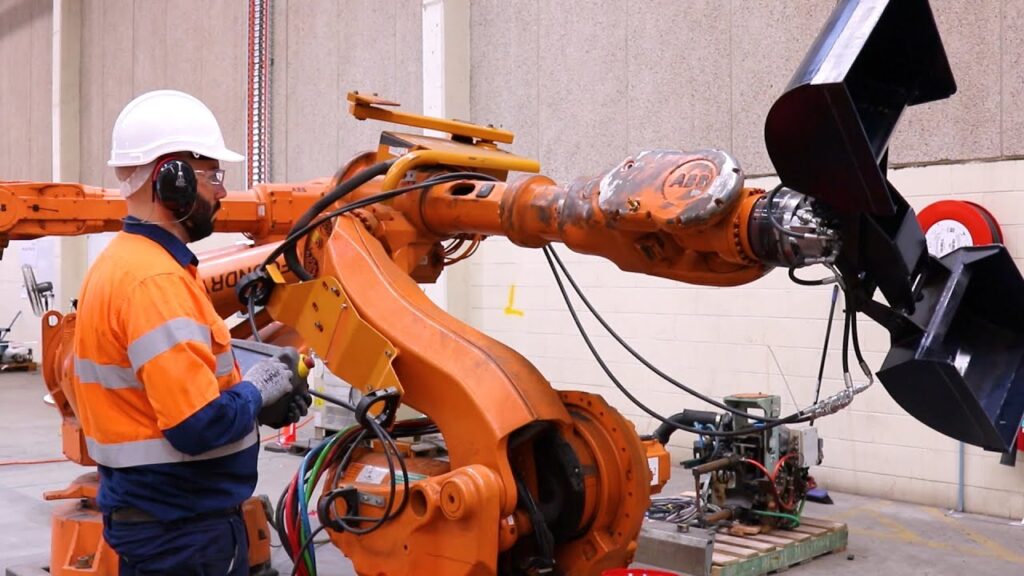

Industrial Robot

"Unleashing the Power of Automation: All-Day Robotic Service for Industrial Needs"