Types of Industrial Robots: A Comprehensive Overview

Industrial robots have revolutionized the manufacturing industry, aiding in increased efficiency, precision, and productivity. These automated machines have become an indispensable asset for companies worldwide, streamlining operations and enhancing overall performance. In this article, we will delve into the various types of industrial robots and explore their wide range of applications.

Explanatory Style:

Industrial robots come in different forms, each designed for specific tasks and equipped with unique capabilities. Let's discuss some of the most commonly used types of industrial robots.

1. Cartesian Robots:

Also known as gantry robots, Cartesian robots operate in a three-axis system using linear slides. These robots are adept at handling heavy loads and excel in applications that require high-speed and precise movements. Their rectangular coordinate system allows for linear movements along the X, Y, and Z axes.

2. SCARA Robots:

Scara robots, which stands for Selective Compliance Assembly Robot Arm, are often used in assembly and pick-and-place operations. These robots have a flexible arm that allows them to move quickly and precisely along the X, Y, and Z axes, resembling a human arm's motion. SCARA robots are particularly efficient in applications that require fast and repetitive tasks.

3. Delta Robots:

Delta robots are recognizable for their unique design, featuring three flexible arms attached to a base. These robots excel in high-speed and precision tasks such as packaging, sorting, and handling fragile objects. Delta robots reduce cycle times and can be found in industries such as food and beverage, pharmaceuticals, and electronics.

4. Collaborative Robots:

Collaborative robots, or cobots, are designed to work safely alongside human operators. These robots are equipped with advanced sensors and programming that enable them to interact with their surroundings and detect human presence. Cobots are highly flexible and can perform various tasks, from assembly to quality control, contributing to improved productivity and worker safety.

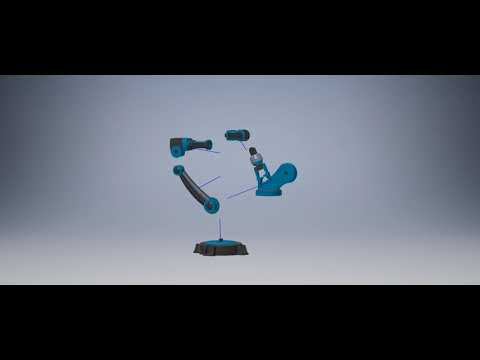

5. Articulated Robots:

Articulated robots are versatile, multi-jointed robots with a wide range of motion. They consist of multiple rotary joints, resembling a human arm, providing enhanced flexibility and reach. These robots find applications in various industries, including automotive, aerospace, and electronics, where they can perform tasks like welding, painting, and material handling.

6. Mobile Robots:

Mobile robots are designed to move autonomously within a defined environment. These robots utilize advanced navigation systems, such as lasers and sensors, to intelligently navigate their surroundings. They are commonly used in warehouse logistics, inventory management, and transportation, helping optimize material flow and operational efficiency.

The Parts of Industrial Robots:

To better understand the capabilities and functionality of industrial robots, it is essential to familiarize ourselves with their key components.

1. Manipulator:

The manipulator comprises the actual robot arm, consisting of links and joints that mimic human limb movements. This component is responsible for executing tasks with precision and accuracy.

2. End Effector:

The end effector, also known as the robot's "hand," is the tool or device attached to the robot's arm. Grippers, sensors, welders, and suction cups are examples of end effectors. They enable robots to interact with the environment and perform specific tasks.

3. Controller:

The controller serves as the 'brain' of the robot, housing the programming and algorithms necessary for its operation. It interprets commands from the operator or a central control system, translating them into precise movements and actions.

4. Sensors:

Sensors play a crucial role in industrial robots, aiding in perception and feedback. Proximity sensors, vision systems, force sensors, and tactile sensors assist in detecting objects, measuring distances, and ensuring safe and accurate operations.

Conclusion:

The advancements in industrial robotics have revolutionized the manufacturing landscape, enabling companies to achieve unprecedented levels of efficiency, precision, and productivity. Understanding the different types of industrial robots and their respective applications is essential for businesses looking to optimize their operations and stay competitive in today's fast-paced industry.

From Cartesian robots for heavy-duty tasks to collaborative robots fostering cooperation between humans and machines, each type of industrial robot brings its unique set of advantages and capabilities to the table. As technology continues to evolve, we can expect further advancements and innovations in the field of industrial robotics, leading to even more efficient and sophisticated machines.

By harnessing the power of industrial robots and leveraging their diverse applications, businesses can unlock new opportunities for growth, improve product quality, and enhance worker safety. The future of industrial automation is undoubtedly bright, with robots playing an increasingly significant role in reshaping manufacturing processes globally.

Industrial Robot

"Exploring the Components and Varieties of Industrial Robots: A Comprehensive Guide to Understanding and Utilizing Robotic Technology"