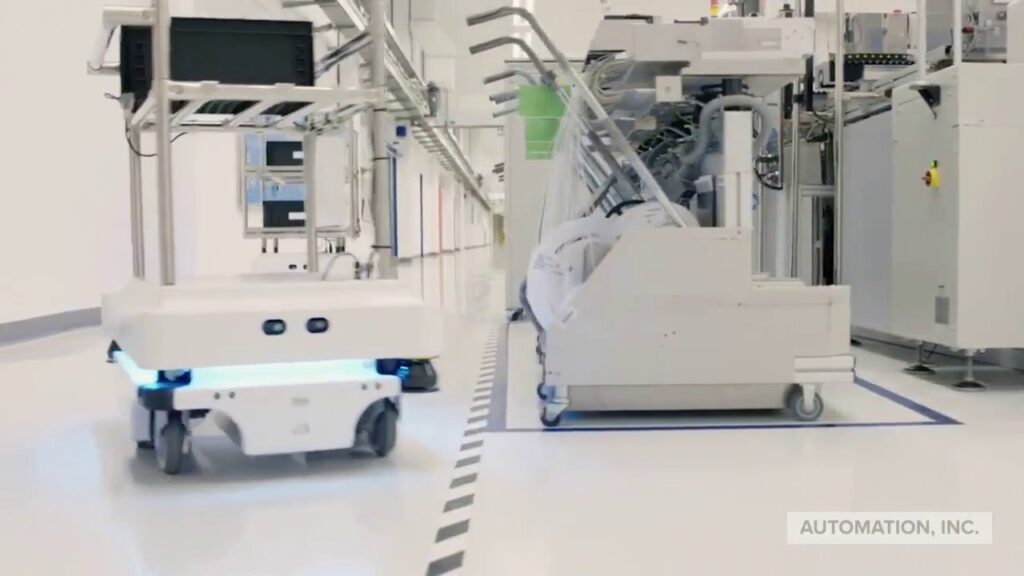

Mobile Industrial Robots (MiR) can automate your internal transportation needs with their collaborative robots. These robots have revolutionized the way industries handle logistics and transportation within their facilities. With advanced technology and innovative features, MiR robots have become a game-changer in the industrial automation sector.

Industrial robots have been widely used in the manufacturing industry for decades. They have significantly improved efficiency and productivity by taking over repetitive, mundane tasks that were previously performed by human workers. However, traditional industrial robots were often large and fixed in one location, limiting their flexibility and adaptability.

Enter MiR, with their range of mobile robots designed specifically for internal transportation. These robots are collaborative, meaning they can work alongside human workers, sharing the same workspace without the need for safety cages or barriers. This makes them ideal for industries where collaboration between humans and robots is necessary.

MiR robots are equipped with advanced sensors and built-in safety features that allow them to detect obstacles, avoid collisions, and navigate through complex environments. They can map their surroundings in real-time, plan optimal routes, and adjust their paths accordingly. This ensures smooth and efficient transportation of goods within the facility, without any interruptions or delays.

The flexibility of MiR robots is another notable advantage. They can easily be programmed to perform different tasks and adapt to changing needs. Whether it's moving products from one station to another, delivering materials from the warehouse to the production floor, or transporting finished goods to the shipping area, these robots can handle it all.

One of the key benefits of using MiR robots is the significant reduction in labor costs. By automating internal transportation, companies can eliminate the need for manual material handling and free up their workforce to focus on more value-added tasks. This not only increases productivity but also improves overall worker satisfaction and reduces the risk of injuries caused by lifting heavy objects.

In addition to labor cost savings, MiR robots offer other financial advantages. They are energy-efficient, requiring minimal power consumption. They also have a long battery life, allowing them to operate continuously for extended periods. This reduces the need for frequent recharging or battery replacements, resulting in lower operating costs.

MiR robots are also designed with user-friendliness in mind. They come with an intuitive interface that makes programming and operating them straightforward, even for non-technical users. This means that companies can quickly implement these robots into their existing workflows without the need for extensive training or hiring specialized personnel.

Furthermore, MiR robots are highly scalable. As a company's production and transportation needs grow, additional robots can easily be deployed and integrated into the existing fleet. This scalability ensures that the robots can keep up with the changing demands of the industry and provide a long-term solution.

The success stories of companies that have implemented MiR robots are numerous. From small-scale operations to large enterprises, these robots have proven their worth in various industries, including automotive, electronics, pharmaceuticals, and logistics. Companies like Industrial Robotics Co. and Automation Systems Ltd have witnessed significant improvements in efficiency, productivity, and overall operational performance after integrating MiR robots into their facilities.

In conclusion, the emergence of Mobile Industrial Robots (MiR) has revolutionized internal transportation in industries. With their collaborative and mobile nature, these robots have made internal logistics smarter, more efficient, and cost-effective. They have helped companies streamline their operations, increase productivity, and improve worker satisfaction. The future of internal transportation lies in the hands of MiR robots, and it's an exciting time for the industrial automation sector.

Industrial Robot

"Transforming the Manufacturing Industry: A Comprehensive Compilation of Mobile Industrial and General Robots"