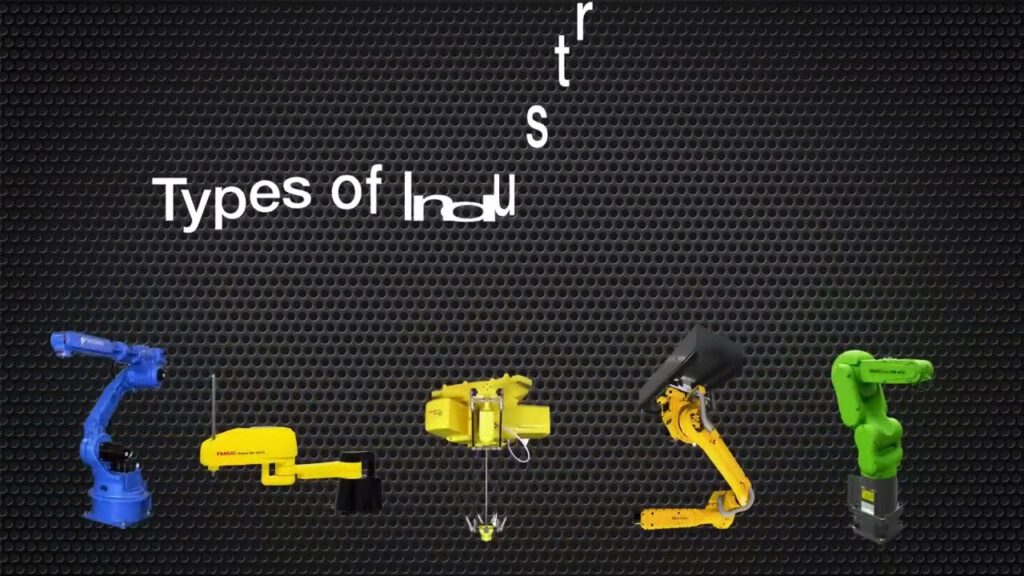

Types of Industrial Robots

Industrial robots have revolutionized the manufacturing industry by automating various tasks and improving efficiency. These advanced machines come in a variety of types, each with its own unique features and capabilities. In this article, we will delve into the different types of industrial robots and explore the benefits they offer.

One of the most common types of industrial robots is the articulated robot. As the name suggests, this robot is characterized by its articulated arm, which consists of several linked segments. This design allows for a wide range of motion and flexibility, making articulated robots ideal for tasks that require precision and intricacy. They are often used in assembly lines, welding, material handling, and painting applications.

Another type of industrial robot is the SCARA robot. SCARA stands for Selective Compliance Assembly Robot Arm, and it is specially designed for tasks that involve fast and precise movements in a horizontal plane. SCARA robots are commonly used in pick and place operations, packaging, and assembly processes. Their ability to move quickly and accurately makes them highly efficient and reliable.

The delta robot is a type of robot that is specifically designed for high-speed pick and place applications. It consists of three arms connected to a central platform, giving it a triangular shape. Delta robots are known for their incredible speed and precision, making them ideal for tasks that require quick and repetitive motions, such as sorting, packaging, and food handling.

Collaborative robots, or cobots, are a more recent development in the field of industrial robotics. Unlike traditional robots, cobots are designed to work alongside humans, enhancing productivity and safety in the workplace. They are equipped with advanced sensors and control systems that allow them to interact with their human counterparts. Cobots are used in a wide range of applications, including assembly, inspection, and machine tending.

Autonomous mobile robots (AMRs) are a type of robot that can navigate and operate autonomously in an industrial environment. These robots are equipped with sensors and mapping technology that enable them to move around the facility without human intervention. AMRs are commonly used in material handling, logistics, and warehousing applications, as they can transport goods efficiently and adapt to changing environments.

In recent years, the field of robotics has witnessed the emergence of exoskeleton robots. These wearable robotic devices are designed to enhance the strength and endurance of human workers. Exoskeleton robots are often used in industries that involve heavy lifting or repetitive tasks, such as construction, manufacturing, and healthcare. They provide physical support and reduce the risk of injuries, allowing workers to perform their tasks more effectively.

Each type of industrial robot offers unique features and benefits, and choosing the right one depends on the specific requirements of the application. Whether it's the articulated robot's precision and flexibility, the SCARA robot's speed and accuracy, the delta robot's rapid movements, the cobot's collaboration with human workers, the AMR's autonomous navigation, or the exoskeleton robot's physical support, there is a robot available to suit every industrial need.

In conclusion, industrial robots have transformed the manufacturing industry by automating various processes and improving productivity. The different types of industrial robots, such as articulated robots, SCARA robots, delta robots, cobots, AMRs, and exoskeleton robots, cater to specific applications and offer unique features and capabilities. By harnessing the power of these advanced machines, industries can achieve greater efficiency, precision, and safety in their operations.

Industrial Robot

"Discovering the Different Types of Industrial Robots for Enhanced Efficiency and Precision"