Steel Strapping Machine: Enhancing Efficiency in Packaging

In the fast-paced world of manufacturing and logistics, efficient packaging plays a crucial role in ensuring that products can be safely transported and delivered to their intended destinations. Steel strapping, a type of robust strapping material, has proven to be highly effective in securing heavy loads and providing stability during transportation. To further streamline the packaging process, the implementation of a Steel Strapping Machine has become a game-changer. This article explores the benefits of utilizing a Steel Strapping Machine and its impact on improving efficiency in the packaging industry.

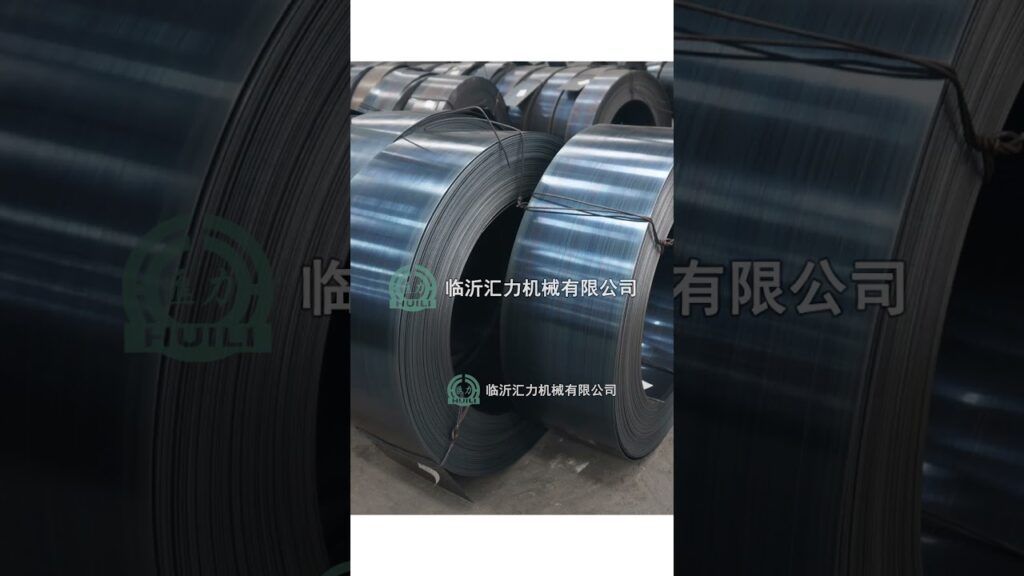

Steel strapping, also known as metal strapping, is widely regarded as one of the strongest and most durable strapping materials available. Its high tensile strength and resistance to various elements make it ideal for securing heavy loads, such as steel coils, lumber bundles, and machinery parts. Traditionally, steel strapping has been applied manually, requiring significant labor and time investment. However, with advancements in technology, the introduction of the Steel Strapping Machine has revolutionized the packaging process.

The Steel Strapping Machine automates the strapping process, offering numerous advantages over manual strapping methods. One of the key benefits is its ability to enhance efficiency. With a Steel Strapping Machine, repetitive and time-consuming strapping tasks can be completed swiftly and accurately. The machine operates at a consistent speed, minimizing human error and increasing productivity. This not only saves valuable time but also reduces labor costs, allowing businesses to allocate resources more effectively.

Moreover, the Steel Strapping Machine ensures a high level of precision and consistency in the strapping process. It eliminates inconsistencies and variations that may arise from human operation, delivering uniform and reliable strapping results. This is particularly crucial when dealing with valuable or fragile goods that require utmost care during packaging. By implementing the Steel Strapping Machine, businesses can significantly reduce the risk of product damage and enhance customer satisfaction.

Additionally, the Steel Strapping Machine offers versatility in terms of customization and adaptability to specific packaging requirements. It can be adjusted to accommodate different sizes and types of loads, providing flexibility in the packaging process. This versatility extends to the strapping itself, enabling businesses to choose from various steel strapping options based on their specific needs. Whether it is high-tensile or regular-duty steel strapping, the machine can efficiently handle the selected strapping material, further enhancing the overall packaging process.

From a safety standpoint, the Steel Strapping Machine provides a reliable solution to reduce potential workplace hazards. Manual strapping can be physically demanding and carries the risk of injuries, particularly when dealing with heavy or cumbersome loads. By automating the process, the machine minimizes the physical strain on workers and significantly reduces the chances of accidents or injuries. This not only protects employees but also contributes to a safer and more efficient working environment.

The implementation of a Steel Strapping Machine also contributes to sustainability efforts within the packaging industry. With increasing awareness of environmental impact, businesses are seeking ways to reduce waste and operate in an eco-friendly manner. Steel strapping is a highly recyclable material, and the automated strapping process ensures minimal material wastage. The machine optimizes strapping usage, reducing unnecessary waste and promoting sustainable practices. By embracing the Steel Strapping Machine, businesses can align themselves with eco-conscious values and strengthen their brand image.

In conclusion, the Steel Strapping Machine has revolutionized the packaging industry by enhancing efficiency, precision, versatility, safety, and sustainability. Its automation capabilities streamline the strapping process, allowing businesses to save time, reduce labor costs, and increase productivity. By eliminating human error, the machine ensures consistent and reliable strapping results, reducing the risk of product damage and enhancing customer satisfaction. Furthermore, its adaptability to various packaging requirements and materials provides flexibility to businesses. The Steel Strapping Machine’s contribution to safety and sustainability further solidifies its position as a must-have tool in the packaging industry. As the demand for efficient and effective packaging solutions continues to grow, embracing the Steel Strapping Machine guarantees a competitive edge in today’s market.

Strapping Machines

“Securing Heavy-Duty Goods: Innovative Tools for Effective Steel Strapping”