Introduction:

If your business is involved in the production of doors, you know that the packing process can be time-consuming and labor-intensive. Fortunately, a door packing machine can help streamline your production and make your life easier. In this article, we will explore the benefits and features of a door packing machine and how it can help you improve your production process.

What is a Door Packing Machine?

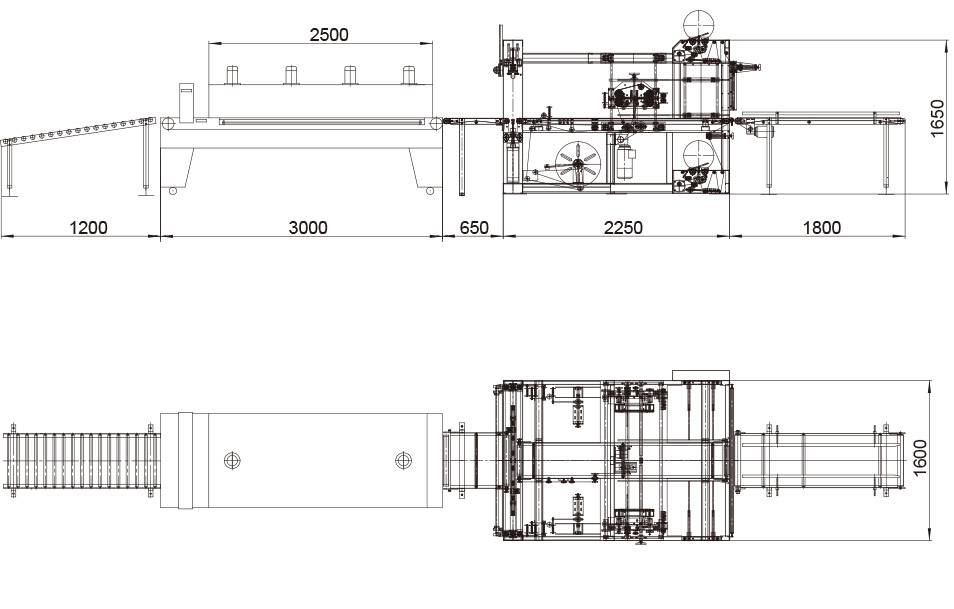

A door packing machine is a piece of equipment designed to automate the process of packing doors for shipping or storage. It can handle a variety of door sizes and types, including wooden, glass, metal, and PVC doors. The machine can wrap doors in various materials such as stretch film, shrink film, or bubble wrap.

Benefits of a Door Packing Machine:

- Improved efficiency: With a door packing machine, you can pack doors quickly and efficiently, reducing the time and labor required for the process.

- Consistent packing quality: The machine ensures that each door is wrapped in the same way, ensuring consistent packing quality for every shipment.

- Cost savings: By reducing the time and labor required for packing, a door packing machine can save your business money in the long run.

- Increased productivity: With the time and labor savings provided by a door packing machine, you can increase your overall productivity and output.

Features of a Door Packing Machine:

- Adjustable settings: A good door packing machine will have adjustable settings to accommodate different door sizes and types of packing materials.

- Easy to operate: The machine should be easy to operate and require minimal training for your staff.

- Durability: The machine should be made of high-quality materials and built to last.

- Safety features: The machine should have safety features to prevent accidents and injuries.

How to Choose the Right Door Packing Machine:

- Consider your production needs: Think about the size and types of doors you produce and how many you need to pack per day. Choose a machine that can handle your production requirements.

- Look for adjustable settings: Choose a machine that can accommodate different door sizes and types of packing materials.

- Consider ease of use: Look for a machine that is easy to operate and requires minimal training for your staff.

- Check for durability: Choose a machine that is made of high-quality materials and built to last.

- Look for safety features: Choose a machine that has safety features to prevent accidents and injuries.

Frequently Asked Questions:

Q: What types of doors can a door packing machine handle? A: A door packing machine can handle a variety of door sizes and types, including wooden, glass, metal, and PVC doors.

Q: What types of packing materials can a door packing machine use? A: A door packing machine can use a variety of packing materials, including stretch film, shrink film, and bubble wrap.

Q: Can a door packing machine be customized to fit my production needs? A: Yes, many door packing machines have adjustable settings to accommodate different door sizes and types of packing materials.

Conclusion:

If you are involved in the production of doors, a door packing machine is an essential tool for streamlining your production process. With a door packing machine, you can pack doors quickly and efficiently while ensuring consistent packing quality for every shipment. When choosing a door packing machine, consider your production needs, ease of use, durability, and safety features. By investing in a door packing machine, you can improve your production efficiency and increase your overall productivity.