Advancements in Material Handling: Revolutionizing the Manufacturing Industry

Material handling is an integral part of any manufacturing process, requiring precision, efficiency, and reliability. In today’s fast-paced industrial landscape, where productivity and cost-effectiveness are paramount, it is crucial to have the right tools and equipment to streamline operations. This is where Handling Machine Manufacturers come into play. They are pioneers in providing custom material handling equipment that revolutionizes the way goods are moved within factories and warehouses.

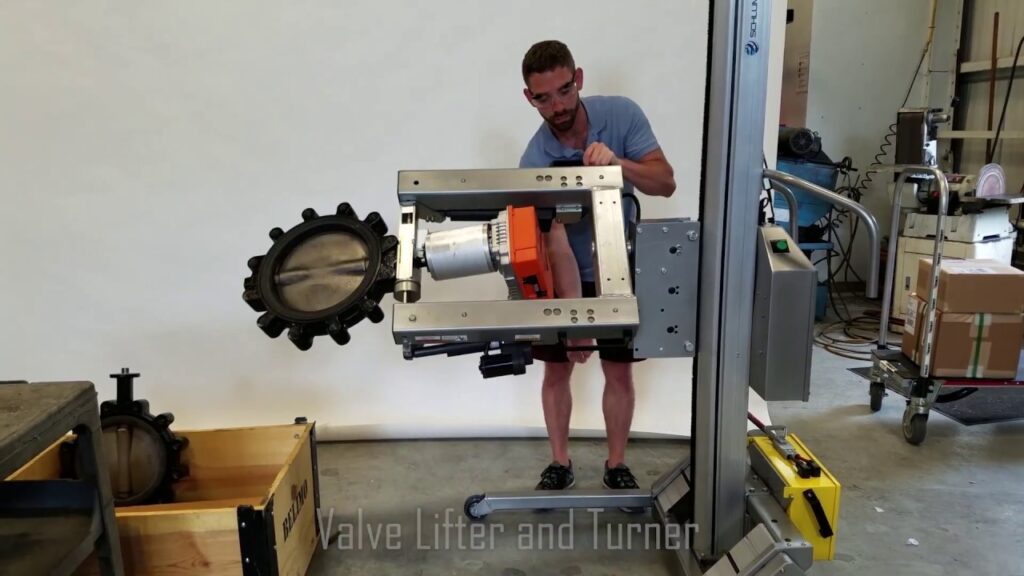

With a diverse range of products and solutions, Handling Machine Manufacturers offer innovative handling systems that cater to the unique requirements of different industries. From automated conveyors and robotic arms to specialized lifting mechanisms and ergonomic workstations, they have a solution for every material handling challenge.

One of the key players in this industry is Ergonomic Handling Group, an established leader in North America. As the go-to source for custom material handling equipment, Ergonomic Handling Group has gained a reputation for its high-quality products and exceptional customer service.

In the fast-paced manufacturing world, efficiency and safety go hand in hand. Companies strive to optimize their processes while ensuring the well-being of their employees. By investing in ergonomic material handling equipment, businesses can achieve both objectives simultaneously.

Ergonomic Handling Group understands the importance of providing equipment that not only boosts productivity but also prioritizes the health and safety of workers. With cutting-edge technologies and innovative design, their products promote proper body mechanics and minimize the risk of musculoskeletal injuries.

To gain a deeper understanding of their operations and the impact of their equipment, I had the privilege of interviewing a technical engineer from Ergonomic Handling Group. This interview sheds light on the company’s philosophy, their commitment to excellence, and their journey as pioneers in the field of material handling.

During the interview, the technical engineer explained how the company’s custom material handling equipment is tailor-made to suit the unique needs of customers. This personalized approach allows them to address specific challenges faced by industries such as automotive, aerospace, pharmaceuticals, and many more.

Moreover, the engineer highlighted the advanced features incorporated into their equipment, such as intelligent automation and intuitive controls. These features not only enhance the efficiency of handling operations but also ensure user-friendly experiences for operators.

Ergonomic Handling Group’s commitment to providing top-notch solutions is evident in their continuous investment in research and development. By staying at the forefront of technological advancements, they consistently introduce groundbreaking equipment that pushes the boundaries of what is possible in material handling.

The impact of their innovations is best exemplified by the case study of a leading automotive manufacturer that partnered with Ergonomic Handling Group to optimize their production line. By implementing their state-of-the-art robotic arms and conveyor systems, the manufacturer not only experienced a significant increase in output but also witnessed a remarkable reduction in errors and accidents. This case study is a testament to the transformative power of advanced material handling solutions.

Looking into the future, Handling Machine Manufacturers like Ergonomic Handling Group are poised to play a pivotal role in shaping the manufacturing landscape. With rapid advancements in technologies such as artificial intelligence, machine learning, and robotics, the potential for innovation in material handling is limitless.

The integration of smart systems and Internet of Things (IoT) capabilities into material handling equipment is one such area of development. Imagine a warehouse where robots collaborate seamlessly with human workers, guided by a network of sensors and interconnected devices. This vision is not far from becoming a reality, thanks to the relentless efforts of Handling Machine Manufacturers.

In conclusion, the contributions of Handling Machine Manufacturers like Ergonomic Handling Group have revolutionized the material handling industry. The availability of custom solutions, their commitment to ergonomic designs, and their pursuit of technological innovation have transformed the way goods are moved within factories and warehouses.

As we embrace the future, it is essential for manufacturers to recognize the importance of investing in material handling equipment that aligns with their unique needs. By doing so, they can unlock new levels of productivity, efficiency, and safety within their operations.

The era of manual labor and inefficient processes is gradually fading away, making room for a new age of smart material handling. With the right partner by their side, businesses can harness the power of advanced technology and bring their manufacturing processes to new heights. Handling Machine Manufacturers are the catalysts of this transformation, and their impact will continue to shape the industry for years to come.

Handling Machine

“Enhancing Efficiency and Productivity with Custom Material Handling Solutions: Innovative Solutions for Manufacturers”