Automated Packaging Systems Revolutionizing the Food Industry

Imagine a world where the tedious task of packaging thousands of products can be done effortlessly and with utmost precision. A world where every step in the packaging process is automated, eliminating human error and increasing efficiency. Welcome to the future of packaging, courtesy of Aliya's Foods and their fully automated packaging line.

The packaging line at Aliya's Foods is a marvel of technology and innovation. It seamlessly transforms raw products into perfectly packaged samosas, leaving no room for error. This state-of-the-art system is a testament to the power of automated packaging systems and their impact on the food industry.

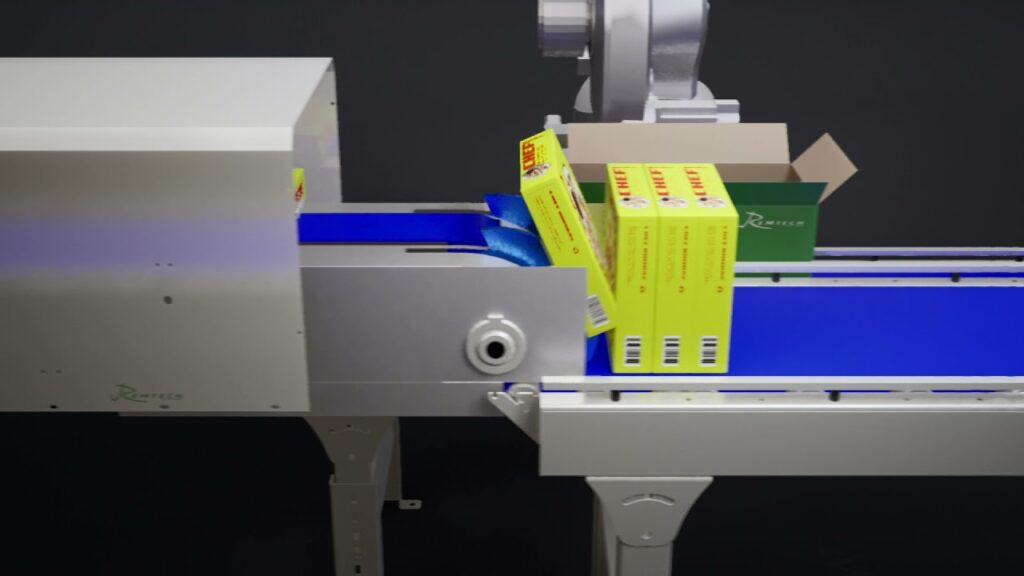

To truly understand the significance of this technology, let's delve deeper into the workings of this automated packaging line. The process begins with the raw samosas placed on a conveyor belt, entering a machine that carefully arranges them into a neat row. From here, each samosa is individually wrapped, ensuring proper hygiene and freshness.

The key to this seamless operation lies in the genius of automated packaging systems. These systems are designed to streamline the packaging process, eliminating the need for manual labor and reducing costs. They can handle large volumes of products with minimal human intervention, allowing businesses to maximize their productivity.

One of the most impressive aspects of Aliya's Foods' packaging line is the precision and speed at which it operates. The automation technology ensures that each samosa is wrapped with precision, eliminating any inconsistencies in the packaging. It's a sight to behold as the machine flawlessly packages samosas at an incredible speed, significantly reducing production time.

But what sets this automated packaging line apart from its counterparts? The answer lies in the cutting-edge technology employed. Aliya's Foods has invested in state-of-the-art machinery that is equipped with advanced sensors, intelligent controls, and robotic arms. These features enable the system to adapt to different sizes and shapes of samosas while maintaining the highest standards of quality.

The benefits of automated packaging systems extend far beyond increased efficiency. By minimizing the need for manual labor, businesses can reduce costs and allocate their resources more effectively. This, in turn, allows them to invest in other areas of their operations, such as research and development or expanding their product line. In short, automated packaging systems provide businesses with a competitive edge in today's fast-paced market.

In addition to the economic advantages, automated packaging systems also contribute to sustainability efforts. With precise portioning capabilities, these systems ensure minimal waste, reducing the overall environmental impact. Furthermore, the ability to track and monitor the packaging process in real-time allows for better quality control and less product recalls, further minimizing waste.

The introduction of automated packaging systems in the food industry has also brought about significant improvements in hygiene and food safety. By reducing human contact in the packaging process, the risk of contamination is drastically reduced. This is particularly crucial in industries like food, where maintaining the highest standards of hygiene is of utmost importance.

Looking into the future, it's evident that automated packaging systems will continue to shape the food industry. As technology advances, we can expect even more sophisticated systems that cater to a wider range of products. The integration of artificial intelligence and machine learning algorithms will further enhance the efficiency and precision of these systems, revolutionizing the way we package and distribute food.

It's important to note that the implementation of automated packaging systems is not limited to large-scale industrial operations. Smaller businesses can also benefit from this technology, albeit on a smaller scale. With modular and flexible systems available in the market, businesses of all sizes can reap the rewards of automation.

In conclusion, Aliya's Foods' fully automated packaging line is a testament to the incredible potential of automated packaging systems. This game-changing technology has revolutionized the food industry, providing businesses with unparalleled efficiency, precision, and cost savings. As we enter a new era of packaging, it's clear that automation is the way forward, paving the way for a brighter and more sustainable future.

Note: This article is based on an animation video showcasing the packaging line at Aliya's Foods. References to specific companies, groups, factories, or third parties have been removed for the sake of objectivity and clarity.

Automatic Packing Line

"Streamline Your Samosas Packaging Process with Advanced Automated Systems"