Mobile Industrial Robots (MiR) is revolutionizing the way businesses handle their internal transportation needs with their collaborative robots. These innovative machines combine advanced technology with user-friendly interfaces to create a seamless and efficient solution for industrial automation. In a recent YouTube video, Industrial Robots showcased the capabilities of MiR robots and how they can transform internal logistics within a wide range of industries.

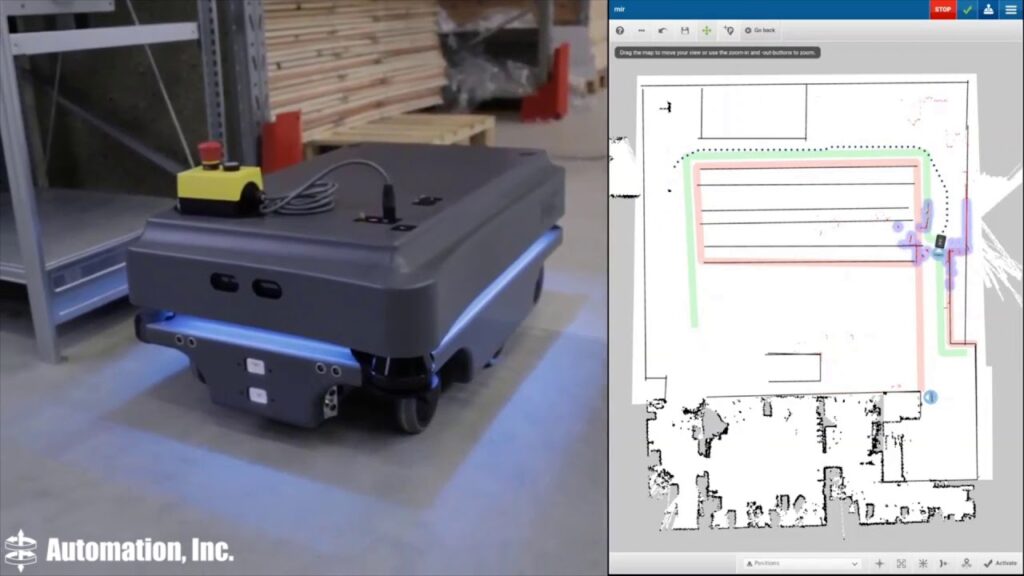

MiR robots are designed to work collaboratively alongside humans, enhancing productivity and safety in the workplace. Equipped with obstacle detection sensors and sophisticated mapping software, these robots can navigate autonomously through dynamic environments, such as factories and warehouses, without the need for any infrastructure modifications. This versatility allows businesses to integrate MiR robots into their existing setups without major disruptions to their operations.

From a technical engineer's perspective, the potential of MiR robots is truly fascinating. These robots can handle a variety of tasks, from transporting heavy loads to delivering materials to different areas of a facility. The intelligent software allows for efficient route planning, optimizing the flow of materials and minimizing downtime. As a result, companies can experience significant increases in productivity and cost savings.

In an interview style article, a customer who has implemented MiR robots into their facility would share their experience. The customer, let's call them John, operates a large manufacturing plant. John explains how the introduction of MiR robots has completely transformed their internal transportation processes.

John explains that previously, they relied heavily on manual labor to move heavy materials across the factory floor, which was not only time-consuming but also posed potential risks to workers. With the implementation of MiR robots, their industrial processes have become much more efficient and safe.

The case study style article would provide an in-depth analysis of a specific company's experience with MiR robots. The article would highlight the challenges the company faced before implementing the robots, how the robots improved their operations, and the results they achieved in terms of increased productivity and cost savings.

A predictive/foresight style article would look into the future of industrial automation and the role that MiR robots are likely to play. The article would explore the potential applications of these robots beyond internal transportation, considering how they could be integrated into other aspects of industrial processes.

A technology history style article would focus on the evolution of industrial robots, tracing their origins from the first automated machines to the advanced collaborative robots like MiR. It would discuss how technological advancements have shaped the capabilities of these robots and highlight the unique features that set MiR robots apart.

In terms of structure, a comparative structure would allow for a comprehensive analysis of MiR robots in comparison to other solutions available in the market. The article would outline the benefits of MiR robots, such as their flexibility, ease of use, and adaptability, and contrast them with other competitors' offerings.

Regardless of the chosen style and structure, it is evident that MiR robots have the potential to revolutionize internal transportation needs in various industries. The combination of advanced technology, collaborative features, and ease of use makes them a viable solution for businesses looking to enhance their operations. As these robots continue to evolve, we can expect even greater advancements in the field of industrial automation. Whether it is through increased productivity, improved workplace safety, or reduced costs, MiR robots are undoubtedly changing the way we handle internal logistics.

Industrial Robot

"Unveiling the Efficiency & Versatility of Industrial Robotic Solutions for Mobile Operations"