Industrial Robots Applications: Revolutionizing Manufacturing Processes

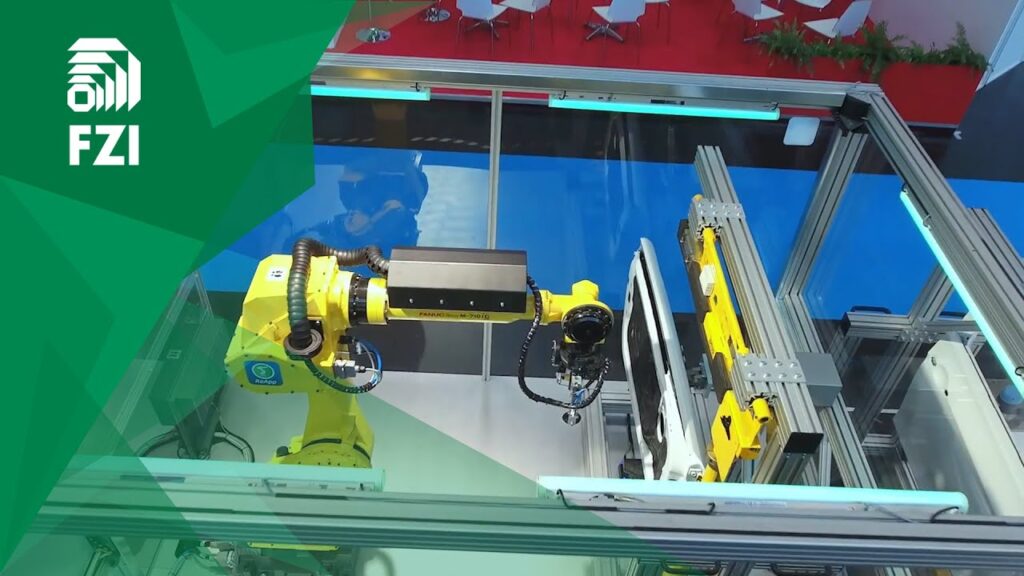

At the AUTOMATICA 2016, the FZI and its partners of the ReApp project demonstrated how an industrial use case can be realized, showcasing the limitless potential of Industrial Robots Applications. The event was an impressive display of cutting-edge technology and its ability to transform the manufacturing sector.

The ReApp project, focusing on ROS-Industrial Applications, brought together experts from various fields to explore how robots can be integrated seamlessly into industrial processes. Their aim was to develop reusable robotic apps that would simplify and optimize manufacturing tasks, increasing efficiency and productivity.

The demo at AUTOMATICA showcased a range of revolutionary applications for industrial robots. One particularly intriguing use case involved the automation of packaging processes. The FZI team had partnered with a leading packaging company to develop a fully automated solution that would streamline the packaging line.

Innovative Robotic Solutions

The integration of Industrial Robots Applications in the packaging process was a game-changer. Traditionally, packaging involved time-consuming manual labor, which was prone to errors and inefficiencies. However, the use of industrial robots transformed the entire process, making it more accurate and much faster.

The demo showed how the robots effortlessly picked up products from a conveyor belt and placed them in designated packaging boxes. The precision and speed at which the robots operated were mesmerizing. It was evident that this automation solution could revolutionize the packaging industry by significantly reducing production time and costs.

These Industrial Robots Applications utilized advanced robotic arms equipped with state-of-the-art sensors and grippers. This level of sophistication allowed the robots to adapt to various product sizes and shapes, ensuring seamless integration into existing manufacturing processes. Moreover, the system was easily configurable, enabling manufacturers to customize it according to their specific needs.

Benefits of Industrial Robots Applications

The applications of Industrial Robots in manufacturing are vast and diverse. They not only enhance productivity but also improve product quality and safety. By taking over repetitive and mundane tasks, industrial robots free up human workers to focus on more complex and value-adding activities.

Additionally, the use of robots mitigates the risk of workplace accidents, as they can handle heavy and hazardous materials with ease. Moreover, industrial robots operate with great precision and accuracy, minimizing errors that could occur due to human fatigue or oversight.

The demo at AUTOMATICA showcased the potential of Industrial Robots to transform manufacturing processes across industries. From packaging to assembly and even quality control, these robots can handle a wide range of tasks with efficiency and reliability.

Future Opportunities

The ReApp project's demonstration at AUTOMATICA has opened up a world of opportunities for manufacturers looking to optimize their operations. The reusable apps developed by the FZI and its partners have the potential to revolutionize many industries and drive productivity to new heights.

Moving forward, it is crucial for manufacturers to embrace Industrial Robots Applications and explore how they can integrate them into their existing processes. This will require collaboration between industry experts and robot manufacturers to develop solutions that are scalable, cost-effective, and highly adaptable.

Conclusion

The demonstration at AUTOMATICA highlighted the immense potential of Industrial Robots Applications in revolutionizing the manufacturing sector. The showcased packaging automation solution was just one example of how robots can streamline processes and increase productivity.

By embracing industrial robots, manufacturers can not only enhance efficiency but also improve product quality and workplace safety. The versatility and adaptability of these robots make them invaluable tools in optimizing manufacturing operations.

As robotics technology continues to advance, it is imperative for manufacturers to stay at the forefront of these developments. The integration of industrial robots can unlock new possibilities, creating innovative and efficient manufacturing processes that will shape the future of industry as we know it.

Industrial Robot

"Revolutionizing ROS-Industrial Applications: Unveiling ReApp@AUTOMATICA 2016 and Industrial Robots' Versatility"