Today, we delve into the exciting world of industrial robotics, where cutting-edge technology meets precision and efficiency. In this article, we explore the fascinating journey of building a 3D printed 6-axis robot arm, a project that promises to revolutionize the way we approach automation.

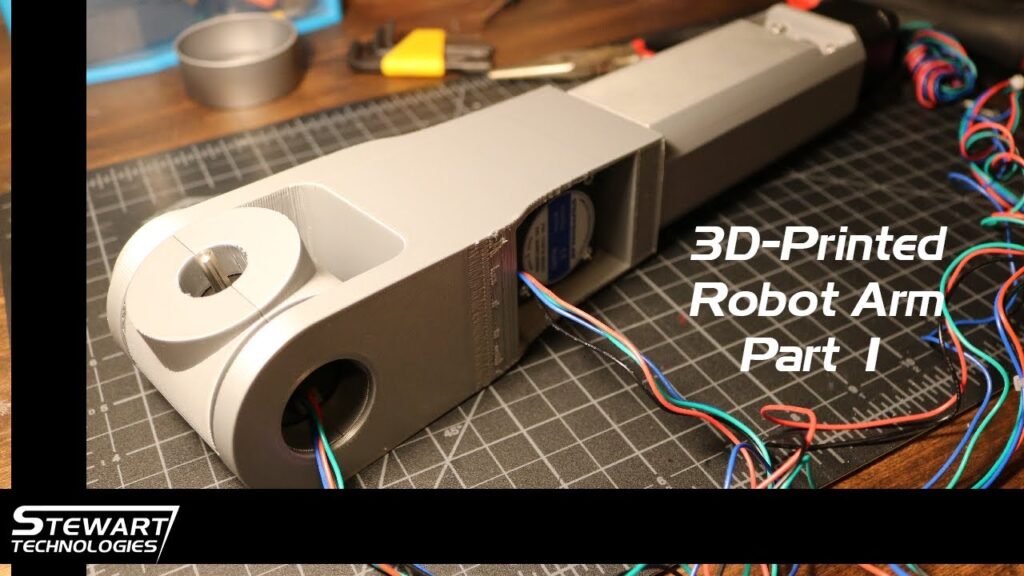

In the awe-inspiring YouTube video titled “3D Printed 6 Axis Robot Arm Part 1 | Upper Joints,” we witness the brilliant mind behind this ambitious endeavor lay out the project’s specifications and delve into the intricate details of assembling the upper joints. This video not only showcases the technical prowess required for such a venture but also highlights the limitless possibilities that lie in the realm of 3D printing and robotics.

The rapid advancements in industrial automation have paved the way for improved efficiency, increased productivity, and enhanced safety in various sectors. The Industrial Robotic Arm at the center of this project embodies these qualities in its quest to redefine the future of automation. Through the integration of 3D printing technology, this arm showcases the limitless potential of additive manufacturing in the realm of robotics.

As we delve into the video, we are introduced to the Technical Engineer responsible for this groundbreaking project. With their in-depth knowledge of robotics and their creative approach to problem-solving, the Technical Engineer serves as the driving force behind this endeavor. Their expertise ensures that every aspect of the 6-axis robot arm is meticulously designed and optimized for maximum performance.

The chosen writing style for this article is Explanatory Style. This style allows us to delve into the intricate details of the project, explaining its significance and potential applications. Through clear and concise explanations, we aim to provide readers with a comprehensive understanding of the 3D printed 6-axis robot arm and its role within the industrial automation landscape.

Adhering to the selected Narrative Structure, we embark on a journey alongside the Technical Engineer, witnessing their thought process and experiencing the challenges and triumphs they encounter throughout the project. This storytelling approach not only keeps readers engaged but also provides valuable insights into the process behind creating such a remarkable piece of technology.

The video begins by outlining the specifications of the project, highlighting the size, weight capacity, and range of motion required for the 6-axis robot arm. These specifications serve as the foundation for the entire design and assembly process, ensuring that the end product meets the desired performance criteria.

With the specifications in mind, the Technical Engineer takes us through the process of assembling the upper joints. They carefully explain each step, from 3D printing the components to assembling the necessary gears and bearings. The use of 3D printing technology allows for intricate designs and lightweight structures, making it an ideal choice for creating the delicate yet sturdy joints of the robot arm.

One of the key advantages highlighted in the video is the cost-effectiveness of 3D printing compared to traditional manufacturing methods. The ability to rapidly prototype and iterate designs significantly reduces production costs and enables more agile development. This affordability makes the 3D printed 6-axis robot arm accessible to a wider range of industries and applications, fuelling further innovation in the field of industrial automation.

As we progress through the video, we witness the Technical Engineer’s meticulous attention to detail, ensuring that each joint is precisely aligned and functions seamlessly. The use of 3D printed components allows for a high degree of customization, catering to specific application requirements. This flexibility is a game-changer in the industrial automation landscape, allowing for tailored solutions that optimize efficiency and productivity.

Furthermore, the Technical Engineer highlights the importance of rigorous testing and quality control throughout the assembly process. By subjecting each joint to extensive testing, they ensure the reliability and durability of the 6-axis robot arm. This commitment to quality serves as a testament to their dedication to delivering a world-class product.

As we reach the conclusion of the video, we are left in awe of the Technical Engineer’s ingenuity and passion for pushing the boundaries of industrial automation. The 3D printed 6-axis robot arm represents a milestone in the realm of robotics, showcasing the power of additive manufacturing and its potential to revolutionize various industries.

In conclusion, the journey of building a 3D printed 6-axis robot arm is a testament to the relentless pursuit of innovation and the remarkable possibilities that lie within the realm of industrial automation. Through the lens of the Technical Engineer, we have witnessed the intricate process of creating this groundbreaking technology. The combination of 3D printing and robotics has opened up a world of possibilities, allowing for more efficient, cost-effective, and customizable solutions. With each advancement, we edge closer to an automated future where precision, efficiency, and ingenuity seamlessly intertwine.

Industrial Robot

“Building a Robotic Arm: Exploring Upper Joints of a 6 Axis 3D Printed Arm (Part 1)”