As the demand for automated packaging and palletizing systems continues to rise, VPEKS Automation emerges as the leading supplier in China, offering complete solutions for businesses in need of efficient and reliable packaging processes. Their state-of-the-art Automatic Packing and Palletizing Line has revolutionized the industry, leading to significant improvements in productivity and cost-effectiveness for a wide range of industries.

With the increasing focus on automation and the integration of advanced technologies, VPEKS Automation has positioned itself as the go-to supplier for businesses in need of automated packing and palletizing solutions. Their cutting-edge technology combined with their expertise in the field has made them a trusted partner for companies seeking to streamline their packaging operations.

One of the major advantages of the VPEKS Automatic Packing and Palletizing Line is its ability to replace labor-intensive processes in industries such as flour milling. Traditionally, these industries heavily relied on manual labor for packaging and palletizing operations, which not only resulted in inefficiencies but also increased the risk of errors and inconsistencies.

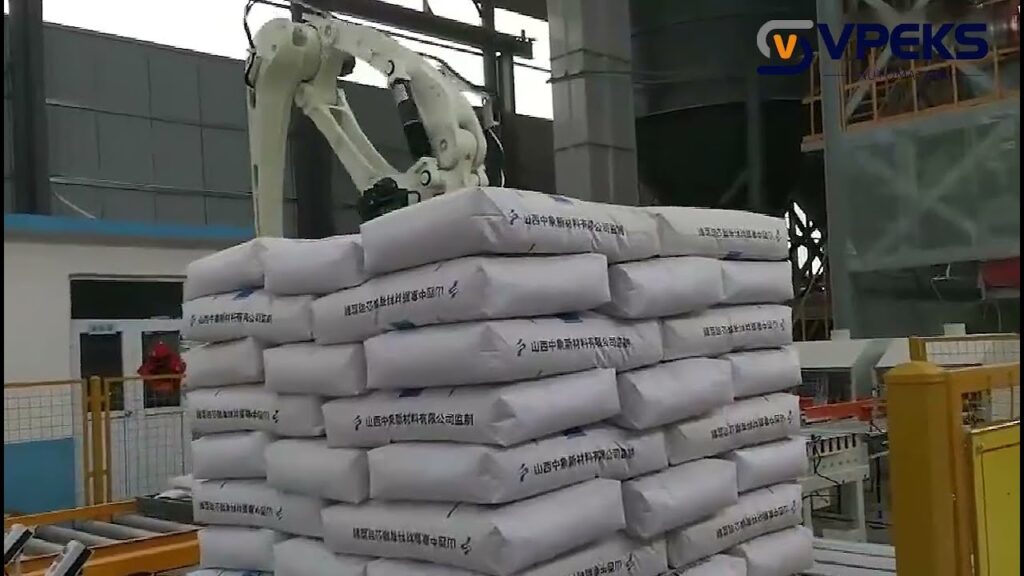

By implementing VPEKS’ automatic palletizing system, flour mills have been able to greatly enhance their production processes. The automated system ensures consistent and accurate palletizing, reducing the risk of product damage and improving overall product quality. Additionally, the system operates at a higher speed, significantly increasing production output, and eliminating the need for manual labor.

The benefits of VPEKS’ automatic palletizing system reach far beyond improved productivity and cost savings. The system also offers enhanced safety measures, as it eliminates the need for workers to manually handle heavy and potentially hazardous products. This not only reduces the risk of workplace accidents but also improves employee satisfaction by providing a safer working environment.

Furthermore, the VPEKS Automatic Packing and Palletizing Line is equipped with advanced sensors and intelligent control systems. These features allow for real-time monitoring and analysis of the packaging process, ensuring optimal efficiency and minimal downtime. Any potential issues or deviations from the set parameters can be detected and addressed promptly, minimizing the chances of disruptions in the production line.

The flexibility and versatility of the VPEKS system are also worth mentioning. It can be easily integrated into existing production lines, allowing businesses to upgrade their packaging and palletizing processes without significant disruptions or the need for extensive modifications. This adaptability makes it suitable for a wide range of industries, including food and beverage, pharmaceuticals, consumer goods, and more.

In conclusion, VPEKS Automation’s Automatic Packing and Palletizing Line has revolutionized the packaging and palletizing industry in China. By offering efficient, reliable, and flexible solutions, VPEKS has become the leading supplier of complete automatic packing systems and robotic palletizing systems. Flour mills, in particular, have benefited greatly from the implementation of VPEKS’ automatic palletizing system, as it has allowed them to replace labor-intensive processes and realize significant improvements in productivity, product quality, and safety. With their commitment to innovation and customer satisfaction, VPEKS Automation continues to set the standard in the field of automated packaging and palletizing systems.

Automatic Packing Line

“Streamlining Flour Mill Operations: Exploring the Efficiency of VPEKS Automatic Palletizing System in Replacing Manual Labor and Traditional Packing Processes”