## Revolutionizing Material Handling with Mechanical Upenders: A Comprehensive Guide

Mechanical upenders are critical pieces of equipment in material handling, transportation, and logistics applications. These machines have revolutionized the way heavy loads are turned, tilted, and transported, making it easier to manage loads that could be otherwise challenging to handle. In this comprehensive guide, we explore the various aspects of mechanical upenders and their roles in revolutionizing material handling.

### What are Mechanical Upenders?

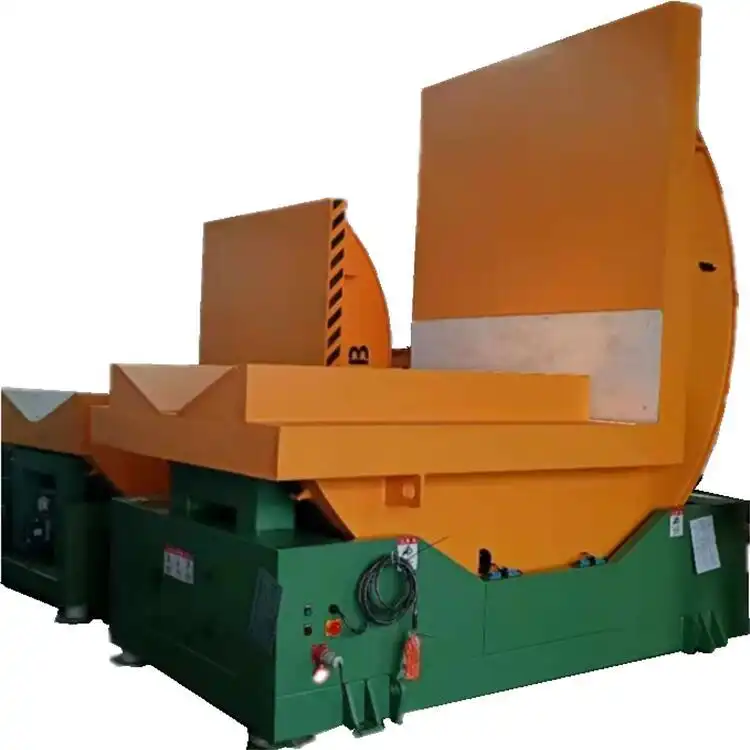

A mechanical upender, also referred to as an industrial upender or a load inverter, is a specialized material handling machine designed to rotate heavy loads on their vertical axis. These machines are used to reorient items that are too big or too heavy to be turned manually. Mechanical upenders are also used in applications where rotating parts of an assembly line is essential. They are indispensable where products need to be transported or where there is a need to maintain a continuous flow of material.

### How Do Mechanical Upenders Work?

Mechanical upenders are built around a robust frame with upender cradles and platforms where heavy loads can be placed. The machine uses hydraulic or electric power to rotate the load on its vertical axis. The turntable on the machine can be set at varying angles to enable a full 360-degree rotation or a partial rotation of up to 180 degrees.

The machine is typically designed to handle loads of up to 50,000 pounds and can rotate loads at a maximum of 40 turns per minute. Mechanical upenders can be used to flip, invert, reposition, or tilt heavy loads, making the dangerous and logistically-challenging process much easier to manage.

### Why are Mechanical Upenders Important in Material Handling?

Mechanical upenders are critical in material handling where heavy loads are handled daily. They have become necessary in applications where managing uneven loads or load reorientation is required. Mechanical upenders help prevent damages to the loads, reduce wear and tear on manual transport systems, and most importantly, protect workers from the risks associated with lifting and handling heavy loads.

Using mechanical upenders minimizes the need for manual labor in material handling, saving time and eliminating the risk of accidents during load inversion, repositioning or tipping. Proper use of mechanical upenders guarantees operations that are faster, smoother, safer, and more accurate.

### What are the Usages of Mechanical Upenders?

Mechanical upenders have diverse applications in manufacturing, logistics, and material handling. They are used to handle different types of products, including paper rolls, metal coils, industrial pipes, and construction equipment.

In manufacturing, mechanical upenders are used to turn, flip or tilt parts during the fabrication process. They are also used for maintenance and repair of aircraft components, engine parts, and vehicle parts. In the logistics industry, mechanical upenders are used to rotate pallets, divert loads to alternate processing lines, or invert products to enhance accessibility during packaging or labeling

### What are the Benefits of Mechanical Upenders?

Mechanical upenders have many benefits. For companies that rely on material handling, using mechanical upenders helps increase productivity without compromising safety standards. Mechanical upenders can improve the accuracy and speed of the material handling process significantly. They also reduce the risks of product damage and worker injuries, translating into fewer work-related compensation claims and reduced worker absenteeism.

Mechanical upenders are beneficial in areas of high labor costs, where heavy lifting and turning items are required. The machines are designed to fit into any industrial process, and they work well in line with other transport and assembly line systems.

### Conclusion

Mechanical upenders are a game-changer in material handling operations. They have revolutionized the way heavy loads are handled, turning an otherwise logistically challenging process into a manageable and safe one. They reduce the risk of worker injuries and damage to products while improving productivity and performance in material handling operations.

Mechanical upenders are an essential tool for plant and factory operations that deal with turning, flipping, or repositioning heavy loads on their vertical axis. Proper use of mechanical upenders guarantees faster, smoother, safer, and more accurate material handling operations.

### FAQ

1. What is the maximum weight that a mechanical upender can lift?

Ans: Mechanical upenders can handle loads of up to 50,000 pounds.

2. Can mechanical upenders be used in the logistics industry?

Ans: Yes, mechanical upenders are used in the logistics industry to rotate pallets or invert products to enhance accessibility during packaging or labeling.

3. What types of products can mechanical upenders handle?

Ans: Mechanical upenders can be used to handle different types of products such as paper rolls, metal coils, industrial pipes, and construction equipment.

4. What are the benefits of using mechanical upenders?

Ans: Mechanical upenders improve the productivity and speed of material handling while reducing the risks of product damage and worker injuries.

5. Where are mechanical upenders used?

Ans: Mechanical upenders are used in manufacturing, logistics, and material handling where heavy loads have to be handled daily.