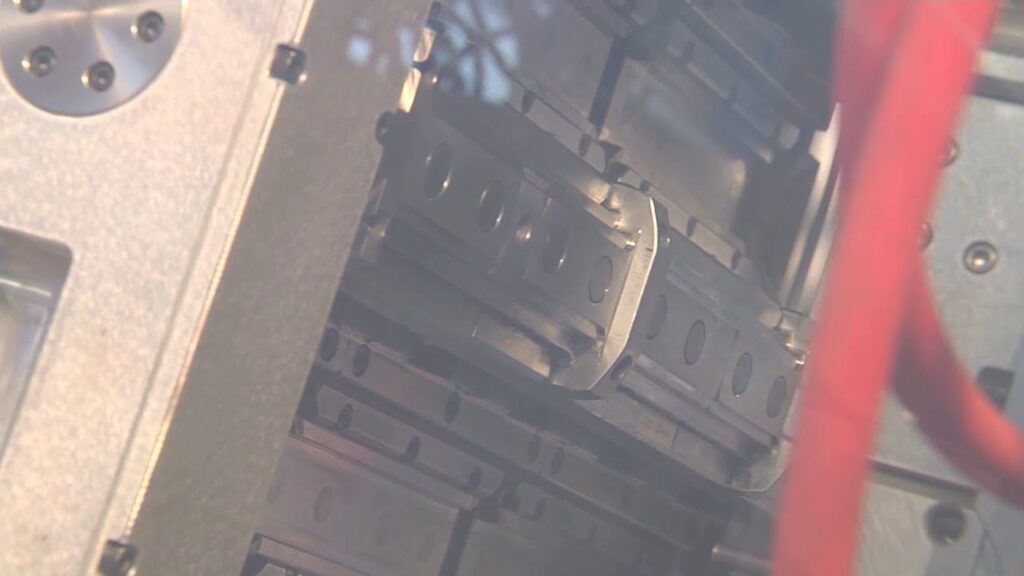

In Mold Assembly (IMA) - Patented: A Revolutionary Single-Stage Procedure for Assembling Multiple Components

Introduction:

Assembly of different components in a single mold often poses a challenge in conventional manufacturing practices, requiring separate handling and assembly of the individual parts. The patented In Mold Assembly (IMA) method revolutionizes this process with a single-stage procedure to integrate multiple components, saving time and costs. In this video, we discuss the main benefits and advantages of IMA that make it a game-changer in the manufacturing industry.

Video Content:

The IMA process involves the use of a single mold to simultaneously assemble two or more different components into a finished product. This eliminates the need for multiple handling and assembly steps, reducing the manufacturing cycle time and costs. IMA is particularly advantageous in the production of complex and intricate products, as it minimizes the risk of errors and disassembly.

Main Benefits:

The main benefits of the IMA process are:

1. Time and Cost Savings: IMA eliminates multiple handling and assembly steps, reducing the manufacturing cycle time and costs.

2. High Accuracy and Precision: IMA ensures accurate, repeatable, and consistent assembly, minimizing the risk of errors and disassembly.

3. Strong and Durable Products: IMA creates strong and durable products by integrating the components in a single molding step, resulting in a stronger bond between them.

4. Versatility: IMA can be applied to a wide range of products, including those with complex geometries and assembly requirements.

Additional Keywords and Tags:

Keywords and tags related to IMA include: manufacturing, molding, assembly, production, efficiency, time and cost savings, accuracy, precision, durability, versatility.

Conclusion:

The patented In Mold Assembly (IMA) process is a game-changer in the manufacturing industry, offering significant benefits in terms of time and cost savings, accuracy, precision, and durability. By integrating multiple components into a single molding step, IMA ensures strong and durable products, while reducing the manufacturing cycle time and costs. Its versatility makes it suitable for a wide range of products, making IMA an essential tool for innovative and efficient manufacturing practices.