Automation Makes Humans' Jobs Easier: Embracing Industrial Automation Robots

In today's fast-paced world, where technological advancements are reshaping industries at an unprecedented rate, automation has emerged as a game-changer. With the help of machines, robots, and control systems, automation has revolutionized various sectors, making human tasks more efficient and less burdensome. Industrial automation robots are now seamlessly integrating into workplaces, revolutionizing industries, such as manufacturing, healthcare, transportation, and beyond. Leveraging the capabilities of these robots, the concept of Industry 4.0 has come to fruition, heralding a new era of efficiency and productivity.

Industrial automation robots are at the heart of the Industry 4.0 revolution, offering a plethora of benefits that enhance the overall functioning of businesses. By automating repetitive and monotonous tasks, robots enable humans to focus on more value-driven and strategic activities. The efficiencies achieved through automation not only reduce costs but also enhance productivity and output quality.

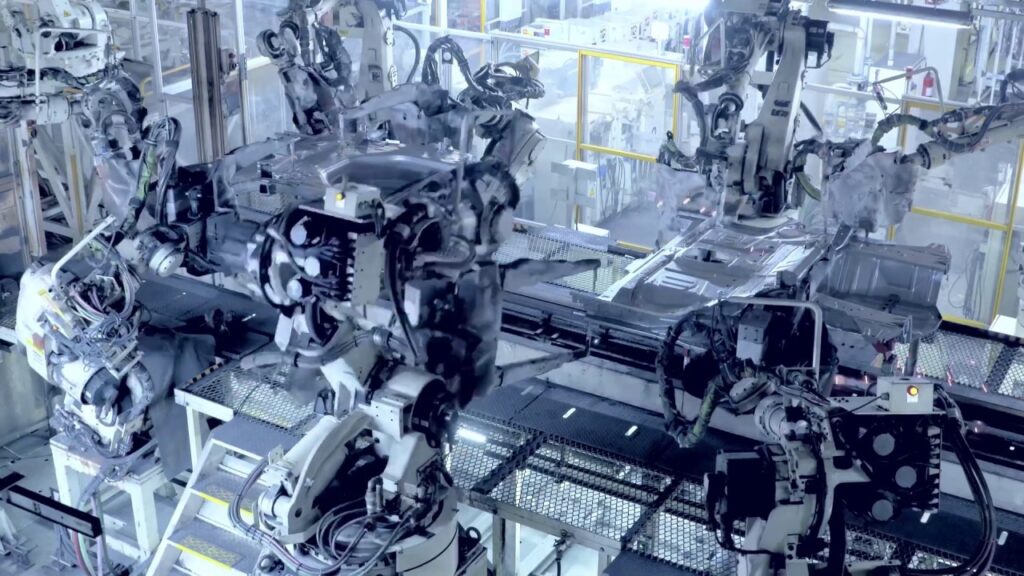

The adoption of industrial automation robots has unlocked a multitude of opportunities for businesses to expand their potential. With these robots working alongside humans, workflows become streamlined, with tasks being completed more accurately and at a faster pace. Take, for instance, a manufacturing plant utilizing robots in the assembly line. These robots possess high precision and accuracy, ensuring consistent product quality while significantly reducing the chance of errors or defects. This elevates the reputation of the company and drives customer satisfaction.

In addition to precision and accuracy, industrial automation robots bring immense efficiency to manufacturing processes. They are capable of working around the clock without a break, thus increasing overall production capacity. With consistent production levels, companies experience reduced lead times and faster time-to-market, enabling them to meet consumer demands swiftly. Furthermore, the use of robots in hazardous and dangerous environments minimizes the risk of accidents, protecting workers' safety and well-being.

One of the major advantages of integrating industrial automation robots into operations is the cost-saving potential. Although the initial investment might seem significant, automation pays off in the long run. By automating tasks that were previously carried out by human labor, companies reduce the dependency on expensive human resources, thus lowering labor costs. Additionally, continuous process improvement and optimization, made possible by automation, result in reduced material waste and energy consumption, offering substantial savings on operational costs.

With the emergence of the Industry 4.0 concept, robotics and automation have not just replaced human labor but have transformed the workforce dynamic. Contrary to popular belief, industrial automation robots are not here to replace humans but rather to complement their capabilities. Robots excel at repetitive, data-driven tasks, while humans thrive in critical thinking, creativity, and problem-solving. Therefore, the collaboration between humans and robots creates a synergistic relationship, amplifying each other's strengths and leading to unprecedented productivity levels.

Adopting industrial automation robots also addresses the pressing issue of labor shortages. In various industries, finding skilled and competent workers is becoming increasingly challenging. By incorporating robotics and automation, businesses can bridge this gap, ensuring a smooth and uninterrupted workflow. This synergy between humans and robots has the potential to create a workforce that is highly efficient, skilled, and technology-savvy.

However, despite the numerous benefits, there are potential challenges and concerns that arise with the implementation of industrial automation robots. The fear of job displacement is a valid concern for many workers in traditional industries. As robots take over the repetitive tasks, the need for human labor might diminish. However, it is crucial to recognize that automation serves as a catalyst for job transformation, rather than elimination. The rise of automation creates new job opportunities that require advanced technological skills, such as robot programming, maintenance, and system optimization. Therefore, investing in upskilling and reskilling programs is pivotal to ensure a symbiotic relationship between humans and robots.

In conclusion, industrial automation robots have become instrumental in shaping the landscape of industries. The fusion of humans and robots through the concept of Industry 4.0 is revolutionizing workplaces, making tasks easier, more efficient, and safer. The benefits of automation, including increased productivity, enhanced quality, reduced costs, and improved worker satisfaction, cannot be overstated. By embracing the potential of industrial automation robots, businesses can position themselves at the forefront of innovation, driving growth, and remaining competitive in an increasingly digitized world. The future is indeed bright with automation leading the way towards a new era of possibilities.

Industrial Robot

"Revolutionizing Manufacturing: Unleashing the Power of Robotics and Automation in Industry 4.0"