Programming an Industrial Robot Using the Oculus Rift

Advancements in technology continue to push the boundaries of industries across the globe. This holds particularly true in the field of robotics, where researchers and engineers work tirelessly to develop innovative solutions that enhance efficiency and productivity. One such groundbreaking development comes from the Laboratory for Computational Sensing and Robotics at Johns Hopkins University, where a team of technical engineers has successfully developed a prototype system that combines industrial robots with the Oculus Rift virtual reality headset.

Industrial robots have proven to be game-changers in various sectors, from manufacturing to healthcare. These robots are designed to perform intricate tasks with precision and accuracy, often replacing human workers in labor-intensive processes. However, programming industrial robots has traditionally been a complex and time-consuming endeavor, requiring specialists to write intricate lines of code. This is where the application of virtual reality comes in.

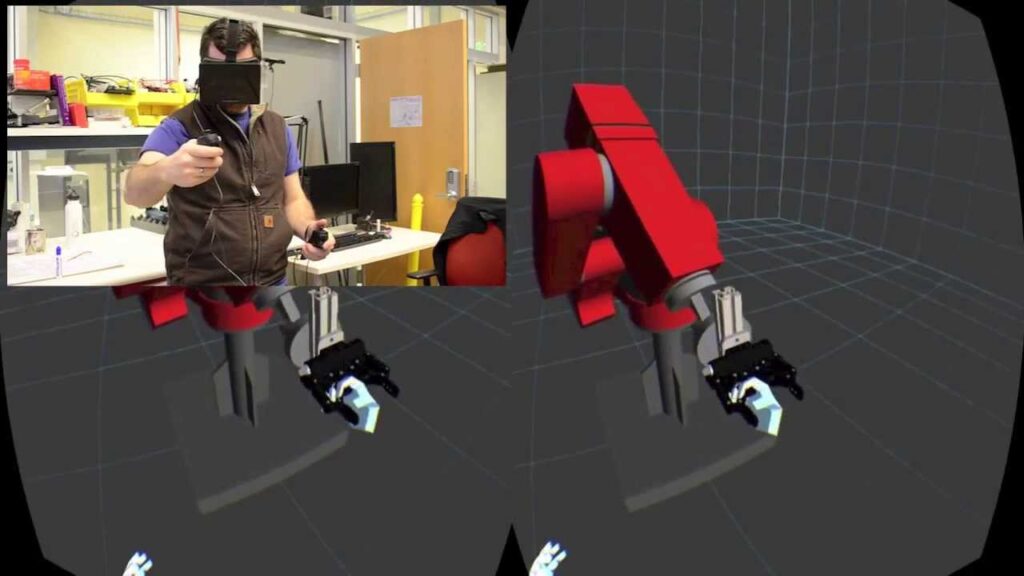

In a recent YouTube video, the team at Johns Hopkins University showcased their revolutionary system, which allows operators to program industrial robots using the Oculus Rift headset. The Oculus Rift, originally known for its applications in the gaming industry, provides users with an immersive virtual reality experience. The researchers at Johns Hopkins University have harnessed this technology and adapted it to simplify the programming process for industrial robots.

The system works by translating the movements and gestures made by the operator wearing the Oculus Rift headset into specific commands for the industrial robot. This intuitive approach allows users to program robots through physical interactions rather than relying solely on lines of code. The user can see a virtual representation of the robot’s movements and make real-time adjustments, ensuring precise positioning, speed, and trajectory.

The implications of this development are far-reaching. Firstly, it significantly reduces the barrier to entry for operating and programming industrial robots. The Oculus Rift interface simplifies the process, making it more accessible to a wider range of operators. This means that small and medium-sized enterprises, previously deterred by the complexities of robot programming, can now leverage this technology to enhance their productivity.

Additionally, the use of virtual reality enhances safety in industrial settings. Traditional methods of programming industrial robots often necessitate operators to be in close proximity to the robots themselves, which can pose risks. With the Oculus Rift system, operators can program robots from a safe distance, eliminating the potential for accidents or injuries.

The benefits extend beyond programming efficiency and safety. The immersive nature of the Oculus Rift allows operators to gain a better understanding of the robot’s capabilities and limitations. This firsthand experience enhances troubleshooting and debugging processes, as operators can quickly identify issues and make necessary adjustments.

Furthermore, the integration of virtual reality with industrial robots opens up avenues for enhanced collaboration. Multiple operators can wear Oculus Rift headsets and work together in the same virtual environment. This allows for seamless collaboration regardless of geographical distances, ultimately leading to improved efficiency and productivity.

As exciting as this development may be, it is important to acknowledge that it is still in the prototype stage. It will take time for the technology to be refined and optimized for practical applications in various industries. Nonetheless, the potential is immense, and the team at Johns Hopkins University anticipates a future where programming industrial robots using virtual reality becomes the norm rather than the exception.

In conclusion, the combination of industrial robots with the Oculus Rift virtual reality headset presents a significant leap forward in the programming and operation of these machines. Simplifying the programming process, enhancing safety, and facilitating collaboration are just a few of the benefits brought forth by this cutting-edge technology. While there is still work to be done before widespread adoption, it is clear that the integration of virtual reality with industrial robots will revolutionize industries and pave the way for a more efficient and productive future.

Industrial Robot

“Virtual Reality Empowers Industrial Robots: Programming Automation with Oculus Rift”