## Industrial Robots in Manufacturing: Revolutionizing Efficiency and Safety

Industrial robots have significantly transformed the manufacturing industry, revolutionizing the way tasks are performed and optimizing production processes. These machines, equipped with advanced technology and impressive capabilities, have become vital assets for companies seeking to enhance efficiency, improve precision, and ensure workplace safety. In this article, we will delve into the impact of industrial robots in manufacturing, exploring their benefits, functions, and the future they hold.

As manufacturing processes become more complex and demanding, the need for reliable and efficient solutions has never been greater. Industrial robots have emerged as the answer to these challenges, offering a wide range of possibilities that were previously unimaginable. Whether it be assembly, welding, material handling, or painting, these robots have proven their worth in various applications across different industries.

One notable advantage of industrial robots is their ability to increase efficiency and productivity. Unlike human workers, robots do not require breaks, are immune to fatigue, and can operate continuously at maximum capacity. Additionally, their precision and accuracy eliminate the risk of errors, resulting in higher-quality products and reduced waste. By automating repetitive and mundane tasks, robots free up human resources, which can be redirected to more skilled and creative tasks, thus contributing to overall productivity and job satisfaction.

Furthermore, industrial robots have significantly improved workplace safety by taking on hazardous and dangerous tasks that pose risks to human workers. By employing robots in areas such as welding and material handling, manufacturers can eliminate the potential for injuries caused by accidents or exposure to harmful substances. This not only ensures the well-being of workers but also reduces insurance costs and minimizes the risk of lawsuits. In this way, industrial robots play a crucial role in promoting a safe and secure working environment.

The integration of artificial intelligence and machine learning technologies in industrial robots has further heightened their capabilities. These robots can now adapt to changing circumstances, learn from experience, and make decisions in real-time. With the ability to analyze vast amounts of data, robots can optimize their performance, make adjustments on the fly, and identify room for improvement. This continuous learning process allows them to become more efficient over time, enhancing productivity and reducing downtime.

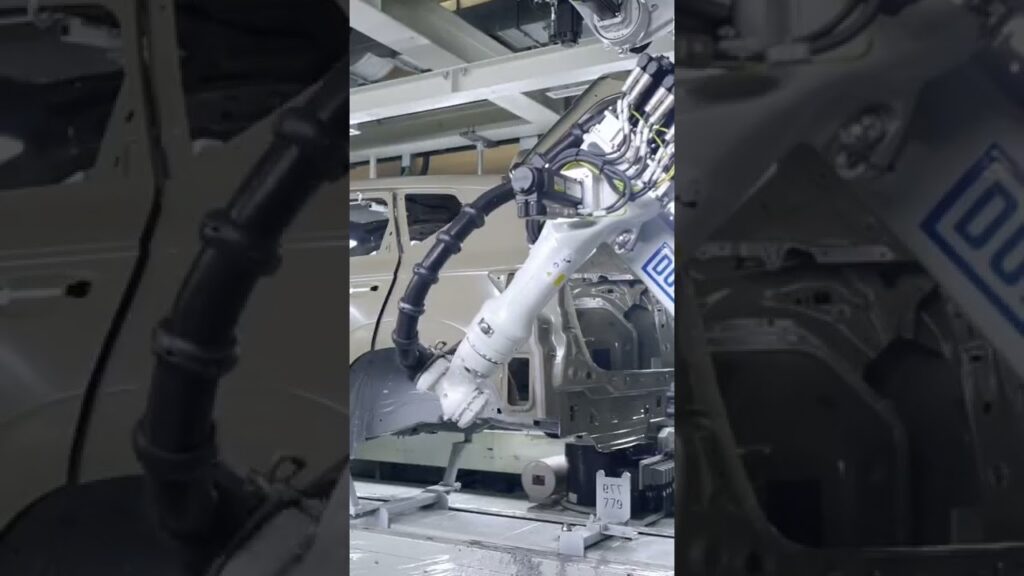

One noteworthy example of industrial robots in action can be showcased through the use of robots in an automotive assembly line. In a video titled "Industrial Robots #shorts," we witness the seamless coordination of multiple robots working in unison to assemble a car. Each robot is assigned a specific task, whether it be welding, painting, or installing components. The precision and speed at which these robots operate is truly remarkable, illustrating their immense value in manufacturing processes.

Looking towards the future, the potential for industrial robots seems boundless. As technology continues to evolve at an unprecedented pace, robots are poised to take on even more complex tasks previously performed solely by humans. The integration of collaborative robots, or cobots, into manufacturing environments opens up new avenues for human-robot interaction and cooperation. These cobots can work alongside humans, assisting in tasks that require dexterity, flexibility, or decision-making that goes beyond the capabilities of traditional robots.

Moreover, the rise of the Internet of Things (IoT) has paved the way for robots to become part of interconnected smart factory ecosystems. By linking robots, machinery, and other devices through a network, manufacturers can achieve higher levels of automation, efficiency, and predictive maintenance. Robots can communicate with each other, learn from shared data, and operate seamlessly within a highly synchronized production system. This interconnectedness not only enhances efficiency but also provides valuable insights that can drive continuous improvement and informed decision-making.

In conclusion, industrial robots have proven themselves to be indispensable assets in the manufacturing industry. With their ability to enhance efficiency, improve precision, and ensure workplace safety, these machines have brought about a revolution in how tasks are performed and production processes are optimized. As technology continues to advance, we can expect even more capabilities and possibilities to be unlocked, allowing industrial robots to play an increasingly pivotal role in the future of manufacturing. The integration of artificial intelligence, machine learning, and the rise of collaborative robots and interconnected smart factories will only serve to further propel the industry forward. The era of industrial robots has arrived, and it is here to stay.

Industrial Robot

"Revolutionizing Manufacturing: A Closer Look at Industrial Robots for Increased Efficiency & Productivity #shorts"