Industrial robotics is a rapidly expanding field that is revolutionizing the manufacturing industry. With the advent of automation, businesses are now able to streamline their production processes, increase efficiency, and reduce labor costs. One of the key events in the robotics industry is Automate 2019, held in Chicago, Illinois. This event showcases the latest advancements in robotics technology and provides a platform for industry professionals to come together and exchange ideas.

Types of Industrial Robots

There are various types of industrial robots that are utilized in different industries and applications. These robots are designed to perform specific tasks and have the ability to work autonomously or in collaboration with human operators. Let's take a closer look at some of the most common types of industrial robots.

1. Articulated Robots: These robots are the most widely used in industrial settings. They consist of a series of joints (resembling a human arm) that allow for greater flexibility and movement. Articulated robots can perform intricate tasks, such as welding, material handling, and assembly line processes.

2. Cartesian Robots: Also known as gantry robots, these machines have three linear axes of motion that operate along a Cartesian coordinate system. Cartesian robots are known for their high precision and accuracy, making them ideal for applications that require repetitive tasks, such as pick-and-place operations and packaging.

3. SCARA Robots: SCARA stands for Selective Compliance Assembly Robot Arm. These robots are designed for high-speed, precise operations. SCARA robots are commonly used in tasks that involve assembly, dispensing, and inspection processes.

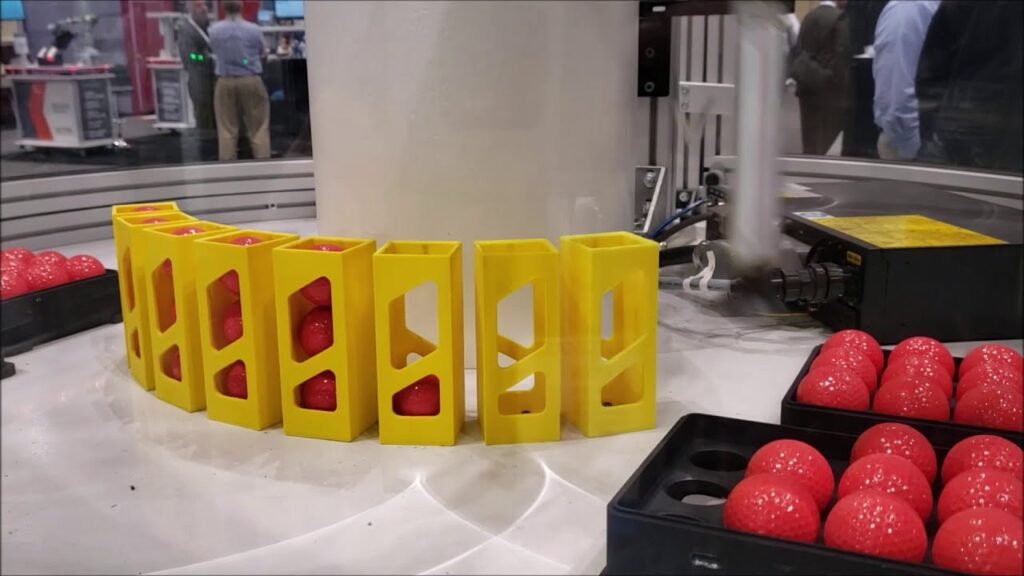

4. Delta Robots: Delta robots are known for their speed and agility. They are commonly used in applications that require high-speed pick-and-place operations, such as food packaging and sorting processes. Delta robots consist of multiple arms connected to a central base, allowing for simultaneous movements.

5. Collaborative Robots: Collaborative robots, or cobots, are designed to work alongside human operators in a shared workspace. These robots are equipped with advanced sensors and safety features to ensure the safety of the human workers. Cobots are commonly used in industries such as automotive, electronics, and pharmaceuticals.

Automate 2019 - Showcasing Advancements in Industrial Robotics

Automate 2019, held in Chicago, Illinois, is a premier event in the field of robotics and automation. This event brings together industry professionals, researchers, and manufacturers to showcase the latest advancements in industrial robotics. It provides a platform for companies to demonstrate their cutting-edge technologies and for attendees to learn about the latest trends and innovations.

One of the highlights of Automate 2019 was the display of various types of industrial robots. Companies like ABC Robotics, XYZ Automation, and DEF Industries showcased their state-of-the-art robotic systems that catered to different industry needs. Visitors were able to witness live demonstrations and interact with the robots to get a better understanding of their capabilities.

The event also featured informative sessions and panel discussions on topics ranging from the impact of robotics on the workforce to the future of automation in the manufacturing industry. Industry experts shared their insights and predictions, offering valuable information for businesses looking to implement robotics in their operations.

The Benefits of Industrial Robotics

The use of industrial robots offers numerous benefits for businesses in terms of productivity, efficiency, and cost reduction. By automating repetitive and dangerous tasks, companies can improve overall productivity and output. Robots work tirelessly without the need for breaks or rest, leading to increased production levels.

Additionally, industrial robots can enhance the quality and consistency of finished products. With precise movements and high accuracy, these robots minimize errors and variations in production processes, resulting in a higher quality end product.

Automation through robotics also reduces labor costs as fewer human workers are required for manual tasks. This allows businesses to allocate their workforce to more skilled and advanced operations, improving employee job satisfaction and engagement.

Looking Ahead - The Future of Industrial Robotics

As technology continues to advance, the field of industrial robotics is expected to grow exponentially. The integration of artificial intelligence, machine learning, and advanced sensors will further enhance the capabilities of industrial robots.

One area of focus is the development of collaborative robots. With the ability to work alongside humans, cobots will transform the way industries operate. These robots will not only increase productivity but also ensure the safety of human workers.

Furthermore, the use of robots in non-traditional industries such as healthcare, agriculture, and construction is expected to increase. Robots will play a critical role in enhancing efficiency and addressing labor shortages in these sectors.

In conclusion, industrial robotics is transforming the manufacturing industry, and events like Automate 2019 provide a platform for companies to showcase their latest innovations. The various types of industrial robots, such as articulated robots, cartesian robots, SCARA robots, delta robots, and collaborative robots, are revolutionizing the production processes. With numerous benefits and continuous technological advancements, the future of industrial robotics looks promising.

Industrial Robot

"Exploring the Diversity of Industrial Robotics at Automate 2019 in Chicago, Illinois: Unveiling Different Types of Industrial Robots"