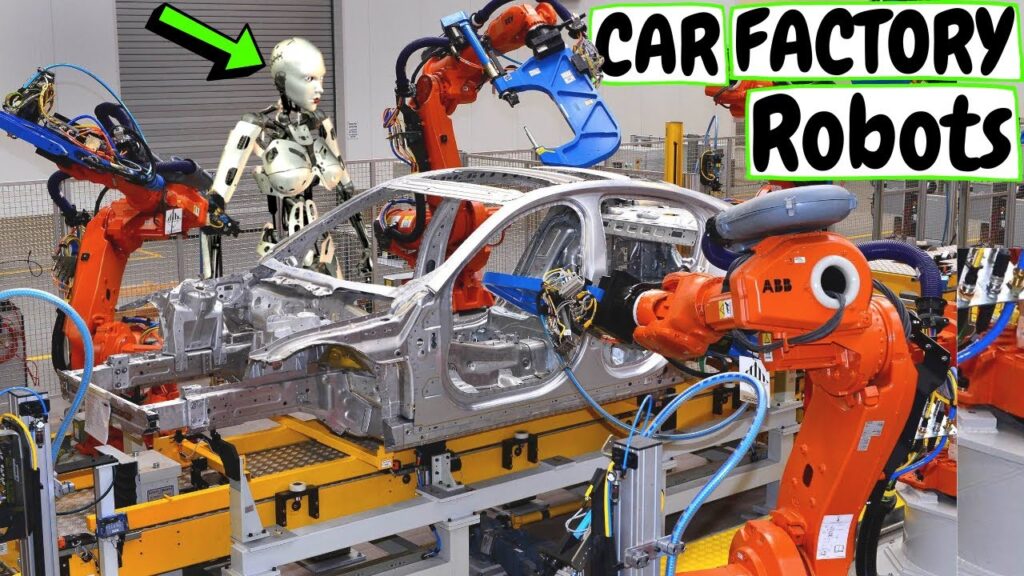

CAR FACTORY: Robots making CARS

Car manufacturing has come a long way in recent years, thanks to advancements in industrial robotics. With the help of robotic arms and automation, the process of building new cars has become more efficient, precise, and cost-effective. In this article, we will take a closer look at how industrial robots are revolutionizing the manufacturing process in car factories.

Manufacturing cars has always been a complex and labor-intensive process. Traditionally, it involved a significant amount of manual work, with human workers performing various tasks such as welding, assembling, and painting. However, with the introduction of industrial robots, these tasks can now be automated, leading to higher production rates and improved quality control.

One of the key advantages of using robots in car manufacturing is their ability to work with extreme precision. Unlike humans, robots are not prone to human errors or fatigue, ensuring consistent and accurate results. This precision is crucial when it comes to tasks like welding, where even a minor mistake can have severe consequences. Industrial robots can perform welds on car bodies with incredible speed and accuracy, ensuring that each joint is strong and reliable.

Another area where robots excel is in the assembly of intricate components. With their dexterity and ability to handle delicate parts, robots can easily navigate complex assemblies and securely fit components together. This reduces the risk of damage during assembly and guarantees a perfect fit, as robots are programmed to align and connect parts with millimeter precision. The result is a well-built car that meets the highest quality standards.

The use of industrial robots also enhances worker safety in car factories. By automating hazardous tasks, such as heavy lifting or exposure to harmful chemicals, robots minimize the risk of accidents and injuries for human workers. This not only protects the well-being of employees but also reduces insurance costs for car manufacturers.

Moreover, industrial robots are incredibly efficient, which translates into significant cost savings for car factories. Robots work tirelessly without breaks or the need for rest, maximizing productivity and reducing production time. Additionally, they can be easily reprogrammed to adapt to different models or manufacturing processes, eliminating the need for costly retooling. This flexibility allows car manufacturers to respond quickly to market demands and produce a wide range of vehicles more efficiently.

The integration of robots into car manufacturing has not only streamlined the production process but also improved overall quality control. Robots are equipped with advanced sensors and vision systems, allowing them to detect defects and anomalies with exceptional accuracy. This ensures that any potential issues are addressed early in the manufacturing process, reducing the likelihood of faulty cars reaching the market. As a result, customers can have confidence in the quality and reliability of the vehicles they purchase.

In conclusion, the introduction of industrial robots in car manufacturing has revolutionized the industry. From welding and assembly to quality control and safety, robots have proven to be valuable assets in the production of cars. With their precision, efficiency, and ability to handle complex tasks, robots are setting new standards for the automotive industry. As technology continues to advance, we can expect even more advancements in the field, further enhancing the capabilities of industrial robots in manufacturing.

Industrial Robot

"Revolutionizing Car Manufacturing: The Role of Industrial Robots in Building and Manufacturing Cars"