The Vegapack PFS-Series Pick, Fill & Seal System: Revolutionizing Bag Packaging

The world of bag packaging machines has seen tremendous advancements in recent years. One particular machine that has caught the attention of many industry professionals is the Vegapack PFS-Series Pick, Fill & Seal system. This cutting-edge machine is specifically designed for higher-speed pre-made pouch filling applications, making it a game-changer in the industry.

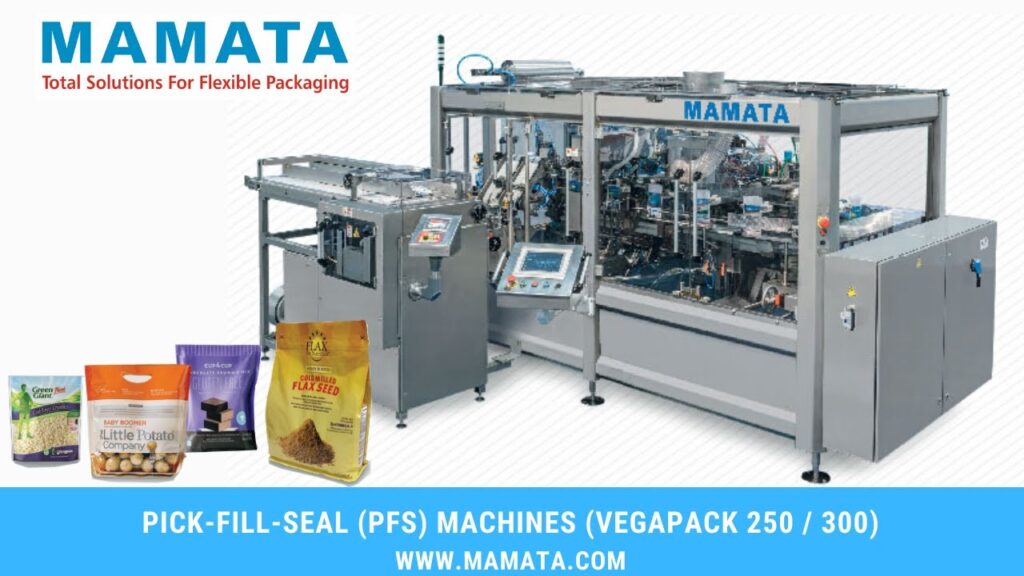

The Vegapack PFS-Series is the brainchild of Mamata Machinery, a reputable manufacturer and exporter of pick-fill-seal pouch packaging machines. With their expertise in bag packaging, Mamata Machinery has introduced a new level of efficiency and productivity with this innovative system.

Operating at an impressive speed, the Vegapack PFS-Series eliminates the need for manual labor, increasing productivity and reducing production costs. This makes it an attractive option for companies looking to streamline their operations and enhance their overall efficiency.

One key feature of the Vegapack PFS-Series is its ability to handle various pouch types and sizes. This makes it a versatile solution for a wide range of industries such as food and beverage, pharmaceuticals, personal care, and more. The machine's flexibility allows for easy adaptation to different product requirements, ensuring optimal packaging results every time.

The pick-fill-seal system is a truly groundbreaking technology that combines multiple functions into a single machine. It starts with the pick function, where the machine accurately picks up pre-made pouches from the stack and brings them to the filling station. This is followed by the fill function, where the machinery efficiently fills the pouches with the desired product. Finally, the seal function ensures a secure and airtight seal, maintaining freshness and quality.

The Vegapack PFS-Series is equipped with advanced sensors and controls that ensure precise filling and sealing. This reduces the risk of product waste and enhances the overall packaging quality. Additionally, the machine's user-friendly interface allows for easy operation and maintenance, minimizing downtime and maximizing productivity.

In terms of packaging efficiency, the Vegapack PFS-Series is second to none. Its high-speed capabilities enable the packaging of a large volume of pouches in minimal time, resulting in increased output and reduced labor costs. The machine's efficiency also extends to its low energy consumption, making it an environmentally-friendly choice for businesses.

Furthermore, the Vegapack PFS-Series offers enhanced packaging safety and hygiene. Its design incorporates strict quality standards to ensure the cleanliness and integrity of the packaged products. With features such as dust-proof mechanisms and easy cleanability, the machine meets the highest industry standards for hygiene.

Overall, the Vegapack PFS-Series Pick, Fill & Seal system is a true game-changer in the world of bag packaging machines. Its speed, versatility, efficiency, and safety features make it an invaluable asset for any company seeking to enhance their packaging operations.

Whether you are a food and beverage manufacturer looking to boost production or a pharmaceutical company in need of reliable and hygienic packaging, the Vegapack PFS-Series is the solution you have been waiting for. With Mamata Machinery's expertise and commitment to excellence, you can trust in the quality and effectiveness of this advanced pick-fill-seal system.

In conclusion, the Vegapack PFS-Series Pick, Fill & Seal system is revolutionizing the way companies approach bag packaging. Its speed, versatility, efficiency, and safety features make it a top choice for businesses across various industries. With Mamata Machinery's expertise backing it, the Vegapack PFS-Series is set to bring about a new era of efficiency and productivity in the bag packaging industry.

Bagging Machine

"Efficient and Versatile Packaging Machines for Pick-Fill-Seal Pouches - Enhance Your Packaging Process Today!"