In today’s rapidly evolving technological landscape, robotic machines have become increasingly advanced and prevalent across various industries. From manufacturing and production to healthcare and logistics, the demand for industrial robots continues to rise. As these machines become more sophisticated and gain popularity in the market, it is crucial to understand the types of industrial robots and their various applications.

Industrial robots, also known as automation robots, are programmable machines designed to perform tasks with high precision and efficiency. These robots are deployed in a wide range of industries to enhance productivity, improve product quality, and ensure worker safety. Let’s delve into the different types of industrial robots and explore their unique functionalities.

1. SCARA Robots (Selective Compliance Assembly Robot Arm)

SCARA robots are widely used in assembly, pick-and-place, and packaging applications. Their design consists of three parallel joints that allow movement in the X, Y, and Z axes. SCARA robots are characterized by their exceptional speed, accuracy, and repeatability, making them ideal for high-speed, repetitive tasks.

2. Articulated Robots

Articulated robots feature rotary joints, resembling a human arm. These robots have a wide range of motion, making them versatile for various applications. Articulated robots find extensive use in tasks such as welding, material handling, and painting. Their ability to navigate complex environments and perform tasks with precision makes them a popular choice in the industrial sector.

3. Cartesian Robots

Also known as Gantry robots, Cartesian robots operate on a three-axis system (X, Y, Z). These robots are well-suited for applications that require heavy lifting, precise positioning, and large-scale assembly. Cartesian robots are commonly used in industries such as automotive manufacturing, where their robust construction and high payload capacity are advantageous.

4. Delta Robots

Delta robots are known for their impressive speed and agility. These robots feature a parallel linkage structure and are equipped with three arms connected to a central hub. Delta robots excel in tasks that require rapid and precise movements, such as packaging, sorting, and assembling small components. Their high-speed capabilities make them particularly useful in industries with high production demands.

5. Collaborative Robots (Cobots)

Cobots are designed to work alongside humans, facilitating a safe and efficient collaborative environment. These robots are equipped with advanced sensors and intuitive programming, enabling them to assist workers in tasks that require precision and dexterity. Cobots have gained popularity in industries such as healthcare, where they support surgeons in delicate procedures or aid in patient rehabilitation.

6. Mobile Robots

As the name suggests, mobile robots have the ability to move autonomously within their environment. These robots utilize various navigation technologies, including GPS, lasers, and cameras, to maneuver in dynamic settings. Mobile robots are commonly used in warehouses, where they assist in material handling, inventory management, and order fulfillment. Their mobility and adaptability make them an indispensable asset in the logistics sector.

7. Exoskeleton Robots

Exoskeleton robots are designed to augment human capabilities, providing strength, endurance, and assistance in physically demanding tasks. These wearable robots find applications in industries such as construction, where heavy lifting and repetitive motions can lead to worker fatigue or injury. Exoskeleton robots help improve worker safety, productivity, and overall well-being.

In conclusion, the rise of robotic technology has revolutionized industries across the globe, driving automation and transforming the way we work. The types of industrial robots discussed in this article represent a fraction of the diverse landscape of robotics. As robotic machines continue to evolve and become more sophisticated, their potential for enhancing productivity, efficiency, and safety in various sectors is immense. By understanding the capabilities and applications of different types of industrial robots, businesses can harness the power of automation to thrive in the modern world.

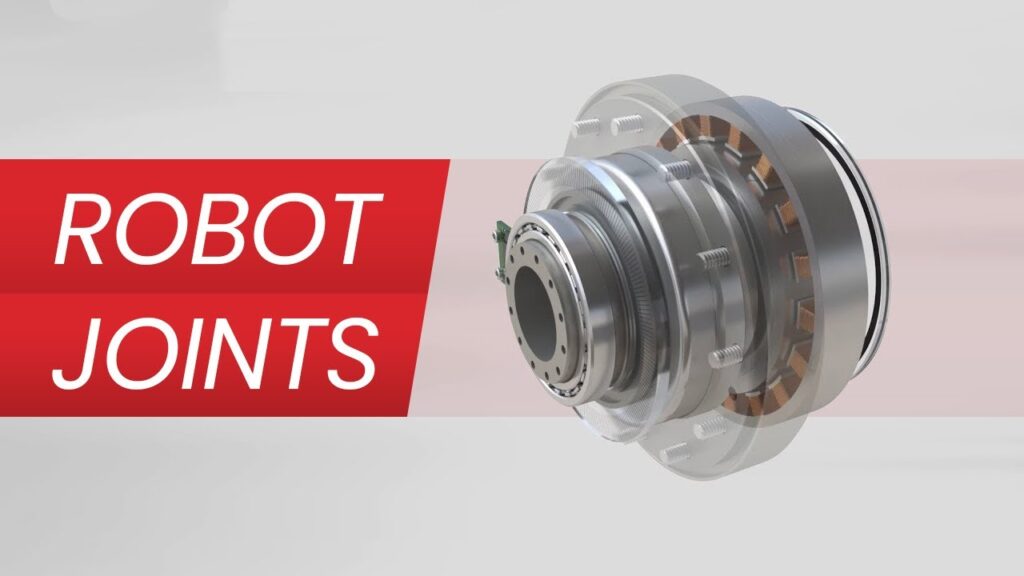

Industrial Robot

“Exploring Robot Joints and Industrial Robot Types: Enhancing Precision and Efficiency in Modern Manufacturing”