ICRA 2018 Spotlight Video Interactive Session Wed PM Pod Q.2 Authors: Messay-Kebede, Temesguen; Sutton, George H. The buzz around ICRA 2018 seems to be all about one particular session that delved into the world of industrial robots. I had the pleasure of attending this session, and I must say, it was an eye-opener. The session shed light on the advancements being made in the field of robotics and the exciting possibilities they hold for various industries.

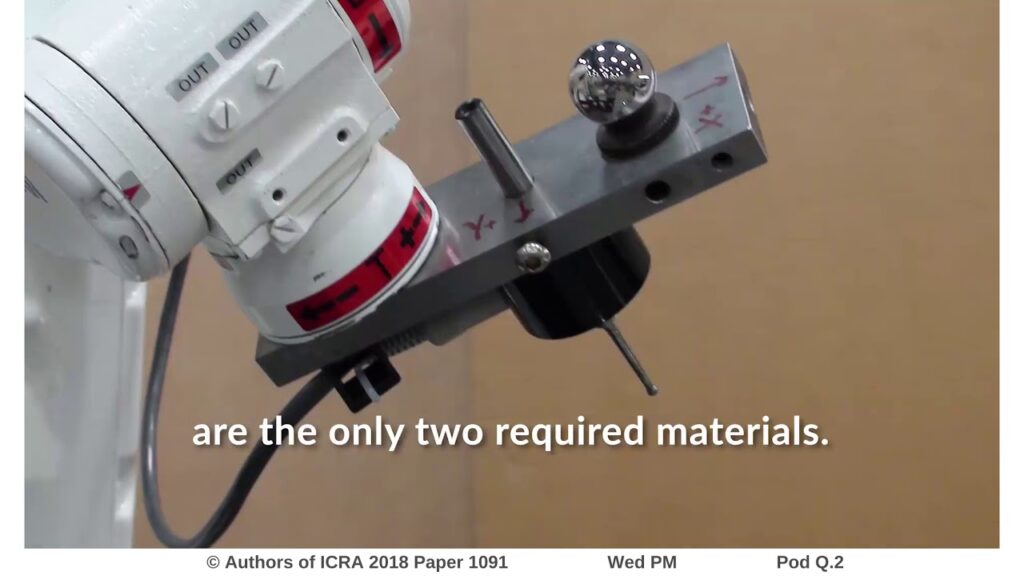

The session primarily focused on the Geometry Based Self Kinematic Calibration Method for Industrial Robots, a groundbreaking technique that is set to revolutionize the way robots are deployed in factories and manufacturing plants. The researchers, Messay-Kebede, Temesguen, and Sutton, presented their findings and demonstrated how this method can enhance the performance and accuracy of industrial robots.

But let’s take a step back and understand why industrial robots are gaining so much attention. With rapidly evolving technology, the need for efficiency and precision in industrial processes has become paramount. This is where industrial robots come in. These mechanical wonders can perform repetitive and labor-intensive tasks with remarkable precision and speed, ultimately boosting productivity and reducing human error.

The Geometry Based Self Kinematic Calibration Method takes the capabilities of industrial robots to the next level. Traditionally, robots have been calibrated using lengthy and complex procedures that involve specialized equipment and manual adjustments. However, this new method simplifies the calibration process by leveraging geometric measurements and algorithms.

One of the major advantages of this method is its ability to calibrate robots in real-time. By continuously monitoring the robot’s kinematics and adjusting it accordingly, the accuracy of the robot’s movements can be significantly improved. This not only reduces errors but also enhances the overall performance of the robot, leading to higher productivity and cost savings for industries.

During the session, the researchers presented several case studies showcasing the effectiveness of this method. One such case study involved a manufacturing plant that used robots for assembling intricate components. By implementing the Geometry Based Self Kinematic Calibration Method, the plant was able to achieve a significant reduction in assembly errors, resulting in better quality products and higher customer satisfaction.

The implications of this method go beyond improved productivity and quality. With more accurate and efficient robots, industries can also ensure the safety of their workers. Tasks that were once considered dangerous or strenuous can now be delegated to robots, minimizing the risk of accidents and injuries.

While the Geometry Based Self Kinematic Calibration Method shows great promise, there are still challenges to overcome. The complexity of the implementation process and the need for specialized knowledge and equipment pose barriers for widespread adoption. However, with further research and development, these challenges can be addressed, opening up a world of possibilities for industries.

In conclusion, the ICRA 2018 Spotlight Video Interactive Session provided a glimpse into the future of industrial robots. The Geometry Based Self Kinematic Calibration Method showcased by Messay-Kebede, Temesguen, and Sutton highlighted the immense potential of this technology to revolutionize industrial processes. With its ability to enhance accuracy, improve productivity, and ensure worker safety, this method has the potential to redefine the manufacturing landscape. As we await further developments, it is clear that industrial robots are not just machines; they are the driving force behind a more efficient and automated future.

Industrial Robot

“Enhancing Robot Accuracy: Discover a State-of-the-Art Calibration Method for Industrial Robots”