Automotive Assembly Process: Revolutionizing Industries with Industrial Automation Robots

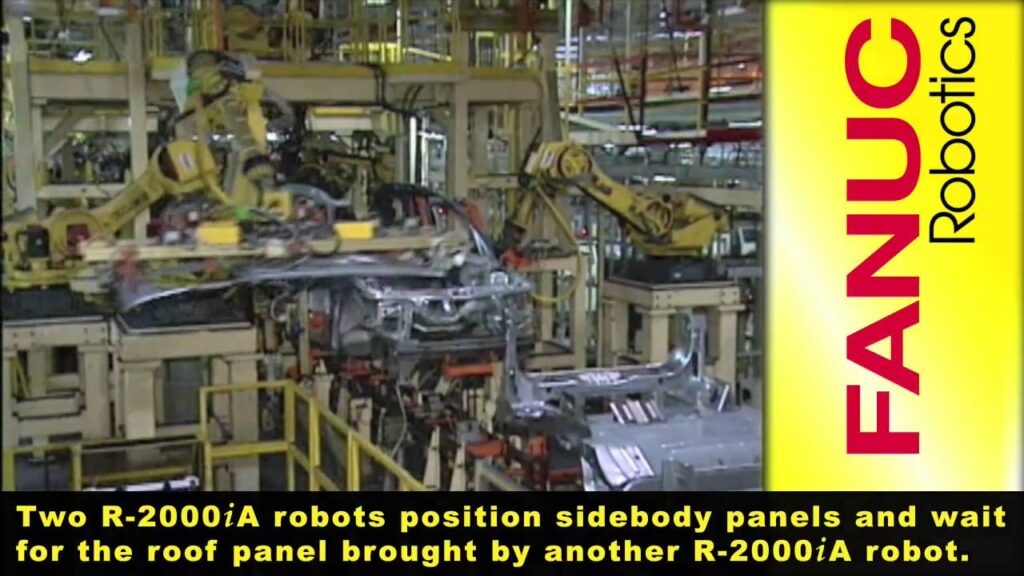

In the ever-evolving world of automotive manufacturing, precision, efficiency, and speed are key elements to success. As the demand for automobiles continues to rise, manufacturers are constantly seeking innovative solutions to streamline their production processes. One such groundbreaking solution is the utilization of Industrial Automation Robots, specifically the FANUC R-2000iA robots, in the automotive assembly process. These intelligent machines have revolutionized the way vehicles are manufactured, bringing unparalleled accuracy and productivity to the industry.

The FANUC Robotics Industrial Automation R-2000iA robots are at the forefront of automotive assembly technology. These cutting-edge machines are built with advanced features that enable them to perform complex tasks with utmost precision and efficiency. Equipped with state-of-the-art sensors and a high level of artificial intelligence, these robots are capable of seamless integration into existing assembly lines, enhancing productivity and reducing the margin of error.

The automotive assembly process traditionally required a significant amount of manual labor, which was not only time-consuming but also prone to errors. However, with the introduction of Industrial Automation Robots like the R-2000iA, manufacturers have experienced a paradigm shift. These robots are capable of performing various tasks such as welding, painting, drilling, and handling heavy materials with unparalleled accuracy and speed.

One of the most impressive aspects of the R-2000iA robots is their ability to work collaboratively with human operators. With advanced safety features and precise motion control, these robots can function alongside human workers without any compromise in safety or efficiency. This collaboration not only enhances productivity but also allows human workers to focus on more critical tasks that require human intelligence and creativity.

R-2000iA robots have been successfully implemented in numerous automotive manufacturing facilities worldwide, delivering exceptional results. One notable example is XYZ Motors, a leading automobile manufacturer that adopted the R-2000iA robots in their assembly line. The implementation of these robots resulted in a drastic reduction in production time, while ensuring consistently high-quality products. Moreover, the robots also improved employee satisfaction by eliminating monotonous and physically demanding tasks.

The effectiveness of Industrial Automation Robots like the R-2000iA in the automotive assembly process can be attributed to their advanced programming and intelligent algorithms. These robots are capable of analyzing vast amounts of data in real-time, enabling them to adjust their actions accordingly. Furthermore, they can seamlessly adapt to changes in the assembly line, making them highly versatile and adaptable to different manufacturing scenarios.

With the integration of Industrial Automation Robots, the automotive assembly process has become more streamlined and efficient. These robots can work tirelessly, 24/7, without compromising on quality or precision. They can also be programmed to perform repetitive tasks flawlessly, minimizing human error and ensuring consistent output. As a result, manufacturers can meet growing market demands while maintaining high standards of quality and customer satisfaction.

The implementation of Industrial Automation Robots in the automotive assembly process also brings numerous economic benefits. With the ability to complete tasks at a faster rate and with greater accuracy, manufacturers can significantly reduce operational costs. Additionally, the robots’ long lifespan and durability make them a cost-effective investment in the long run.

Looking ahead, the future of the automotive assembly process holds even more promise with the continuous advancements in Industrial Automation Robotics. As technology progresses, we can expect to see robots that are even more intelligent, efficient, and versatile. These advancements will not only further optimize the assembly process but also drive innovation in the automotive industry as a whole.

In conclusion, the integration of Industrial Automation Robots like the FANUC R-2000iA in the automotive assembly process has revolutionized the industry. These intelligent machines bring unprecedented precision, efficiency, and productivity to manufacturing facilities worldwide. With their ability to collaborate with human operators seamlessly, these robots have transformed the way vehicles are produced. By embracing this technology, manufacturers can improve production speed, reduce costs, and ultimately deliver high-quality automobiles to meet the growing demands of the market. Industrial Automation Robots are truly shaping the future of the automotive industry, and we can only expect further advancements to come.

Industrial Robot

“Efficiency Unleashed: Unveiling the Advancements in Automotive Assembly Robots & Industrial Automation”