Industrial Robotic Arm: Revolutionizing the Manufacturing Industry

With the ever-evolving advancements in technology, the manufacturing industry has witnessed a significant transformation over the years. One of the most innovative and groundbreaking developments in recent times is the Industrial Robotic Arm. This fully open-source creation, equipped with 6 AXIS stepper motors and cycloidal gearboxes, has proven to be a game-changer in the world of automation.

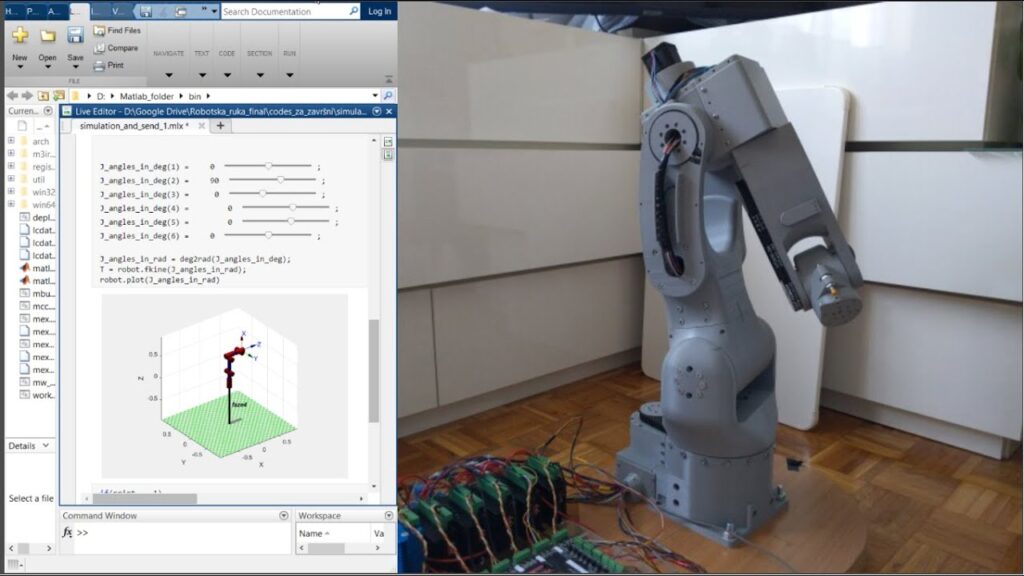

The Faze4-3D printed 6 axis robot arm is a shining example of this revolutionary technology. Boasting an impressive reach of 70 cm, this robotic arm is capable of performing intricate tasks with utmost precision and efficiency. Its lightweight design makes it easy to maneuver, allowing it to seamlessly integrate into various manufacturing processes.

The introduction of this Industrial Robotic Arm has greatly impacted the manufacturing industry, offering countless benefits and opportunities for businesses. Let’s delve deeper into the significance and potential of this remarkable creation.

Efficiency and Accuracy: The Industrial Robotic Arm has proven to be a game-changer when it comes to efficiency and accuracy in manufacturing processes. With its 6 AXIS capabilities, it can effortlessly move and position objects in any direction, mimicking the flexibility and dexterity of the human arm. This ensures precise and error-free assembly, resulting in improved product quality and reduced wastage.

Increased Productivity: By automating repetitive and labor-intensive tasks, the Industrial Robotic Arm significantly increases productivity in manufacturing processes. Its speed and precision allow for faster production cycles, leading to higher output and reduced lead times. This not only boosts overall productivity but also enables businesses to meet customer demands more efficiently.

Safety: The introduction of the Industrial Robotic Arm has also addressed safety concerns in the manufacturing industry. By taking over hazardous tasks, such as handling heavy or toxic materials, the risk of accidents and injuries to human workers is greatly reduced. This ensures a safer working environment and promotes the well-being of employees.

Versatility: One of the most remarkable aspects of the Industrial Robotic Arm is its versatility. Thanks to its open-source nature, this technology can be customized and adapted to suit various manufacturing requirements. Whether it’s welding, painting, pick-and-place operations, or even intricate surgical procedures, this robotic arm has the ability to perform a wide range of tasks with ease.

Cost-Effectiveness: Implementing the Industrial Robotic Arm in manufacturing processes proves to be cost-effective in the long run. While the initial investment may seem significant, the potential for increased productivity, reduced labor costs, and minimized errors outweighs the initial expenditure. Moreover, its open-source nature allows for continuous improvement, ensuring that businesses can stay up-to-date with the latest advancements without incurring hefty upgrade costs.

The Faze4-3D printed 6 axis robot arm, in particular, offers numerous advantages in addition to the aforementioned benefits of Industrial Robotic Arms. By utilizing 3D printing technology, this robotic arm achieves a lightweight yet robust structure, enhancing its efficiency and ease of use. Furthermore, its open-source nature makes it accessible for individuals and businesses alike, promoting collaboration and innovation within the manufacturing community.

In conclusion, the Industrial Robotic Arm, including the remarkable Faze4-3D printed 6 axis robot arm, has revolutionized the manufacturing industry. Its efficiency, accuracy, increased productivity, and versatility have paved the way for significant advancements in automation. As businesses continue to embrace this technology, we can expect to witness further improvements in manufacturing processes, ultimately leading to a more efficient and prosperous future.

Industrial Robot

“Revolutionizing Automation: Unleashing the Power of 3D Printed 6-Axis and Industrial Robotic Arms”