Totally Integrated Automation Revolutionizes End-of-line Packaging with Full Automatic Packaging Line

Imagine a world where production processes are seamless, efficient, and fully automated. A place where machinery communicates flawlessly, eliminating bottlenecks and ensuring optimal productivity. Siemens, renowned for its innovative solutions in the engineering sector, has taken the concept of automation to new heights with its Totally Integrated Automation (TIA) system. At the Hannover Messe 2014, Siemens unveiled its latest masterpiece – the Full Automatic Packaging Line, an end-of-line packaging machine that revolutionizes the way products are packaged and shipped.

The Full Automatic Packaging Line is a marvel of modern engineering, designed to streamline the packaging process and increase overall efficiency. This cutting-edge machine eliminates the need for manual labor, reducing costs and improving productivity. Powered by Siemens TIA system, it seamlessly integrates with other machinery in the production line, ensuring a smooth flow of materials and minimizing downtime.

One of the key features of the Full Automatic Packaging Line is its ability to handle a wide variety of products. From small items like cosmetics to large items like automotive parts, this packaging line can accommodate diverse products with ease. This versatility is made possible by the TIA system, which enables the machine to adapt to different packaging requirements seamlessly.

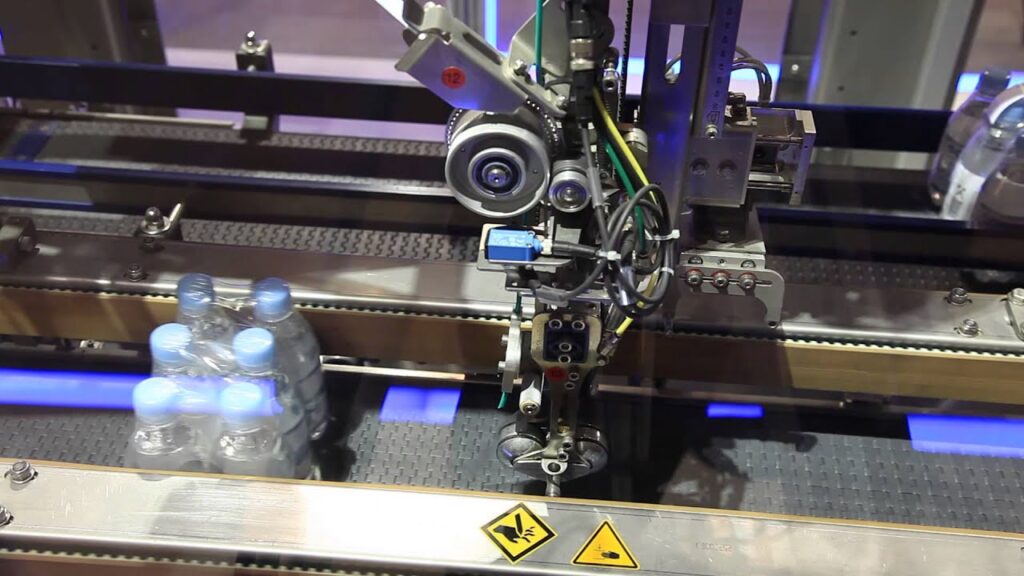

How does the Full Automatic Packaging Line work? The process begins with the products being fed into the machine through a conveyor belt. The TIA system acts as the brain, coordinating the movements of various components such as robotic arms, packaging materials, and labeling systems. With precision and speed, the machine wraps, seals, and labels the products, readying them for shipment. The TIA system ensures that each package is consistent in quality and appearance, maintaining the brand's reputation for excellence.

The Full Automatic Packaging Line is not just a standalone machine; it is part of a larger ecosystem of interconnected systems. Siemens TIA system allows for real-time communication between different machines, enabling data exchange and synchronization. This level of integration ensures that the entire production process is optimized, from raw material handling to product packaging. The TIA system acts as a central nerve center, monitoring and controlling every aspect of the production line, resulting in enhanced efficiency and reduced waste.

One of the outstanding benefits of the Full Automatic Packaging Line is its ability to adapt to changing production needs. With the TIA system, the machine can be easily reconfigured to accommodate different packaging formats or product variations. This flexibility allows companies to respond quickly to market demands, reducing time-to-market and enabling faster innovation.

For companies looking to improve their bottom line, investing in the Full Automatic Packaging Line is a no-brainer. By automating the packaging process, companies can significantly reduce labor costs and minimize errors. The TIA system ensures that every step of the packaging process is monitored and controlled, eliminating the risk of mistakes. Additionally, the machine's high-speed operations enable faster throughput, further enhancing productivity.

Siemens, known for its commitment to sustainability, has also incorporated eco-friendly features into the Full Automatic Packaging Line. By optimizing energy usage and minimizing waste, the machine helps companies reduce their environmental impact. This aligns with the global trend towards sustainable manufacturing practices and positions Siemens as a leader in the field.

In conclusion, Siemens' Totally Integrated Automation system has revolutionized the end-of-line packaging process with its Full Automatic Packaging Line. The combination of seamless integration, versatility, and flexibility makes this machine a game-changer in the engineering sector. With the TIA system at its core, the Full Automatic Packaging Line ensures maximum efficiency, reduced costs, and enhanced product quality. As companies strive to stay ahead in today's competitive market, embracing automation is the key to success. Siemens has once again proven its ability to push the boundaries of innovation, setting new standards for the industry.

Automatic Packing Line

"Enhancing Efficiency: Streamlining End-of-Line Packaging with Complete Automation"