**Title:** Revolutionizing Packaging Efficiency: Exploring Automatic Packing Line Manufacturers

**Introduction**

Packaging plays a crucial role in various industries, ensuring the protection, presentation, and preservation of products. As consumer demands and production volumes continue to rise, the need for efficient and reliable packaging solutions becomes increasingly vital. Automatic packing lines have emerged as a game-changer in this realm, streamlining the packaging process and offering unparalleled benefits. In this article, we will delve into the world of automatic packing line manufacturers, with a particular focus on the DISTILLERS SEMI AUTOMATIC PACKAGING LINE offered by INLINE FILLING SYSTEMS.

**Explanatory Style**

When it comes to optimizing packaging efficiency, automatic packing lines have proven to be a boon for manufacturers. These advanced systems are designed to automate the packaging process, reducing human intervention, and enhancing productivity. Automatic packing line manufacturers play a pivotal role in enabling seamless operations for a plethora of industries such as food and beverage, pharmaceuticals, cosmetics, and more.

**Introduction to Automatic Packing Line Manufacturers**

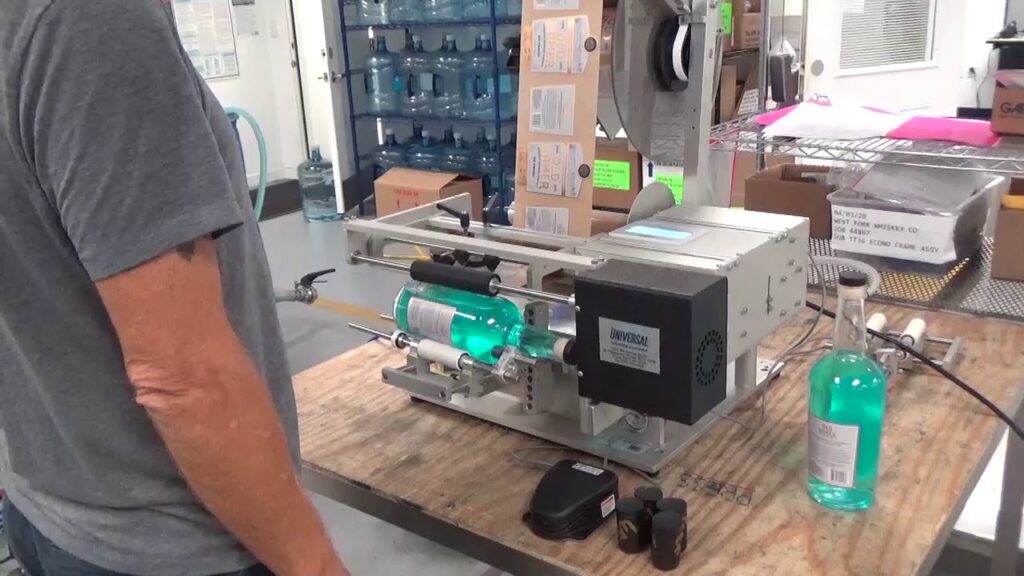

One of the leading manufacturers in this field is INLINE FILLING SYSTEMS, esteemed for their DISTILLERS SEMI AUTOMATIC PACKAGING LINE. This state-of-the-art equipment is designed to meet the unique requirements of the distillery industry. By integrating innovative technologies and engineering excellence, INLINE FILLING SYSTEMS has revolutionized the packaging process for distillers, ensuring precision, reliability, and efficiency.

**Features and Benefits of the DISTILLERS SEMI AUTOMATIC PACKAGING LINE**

The DISTILLERS SEMI AUTOMATIC PACKAGING LINE offers a myriad of features and benefits that have propelled it to the forefront of the industry. Let’s delve deeper into some of its key components:

1. **Automatic Bottle Feeding:** The packaging line incorporates automatic bottle feeding, eliminating the need for manual loading. With a user-friendly interface, operators can effortlessly control and monitor the process, minimizing downtime and maximizing throughput.

2. **Accurate Filling Mechanism:** Precision is paramount in the distillery industry, and the DISTILLERS SEMI AUTOMATIC PACKAGING LINE delivers on this front. The equipment employs a filling mechanism that ensures accurate and consistent volumes of liquid are dispensed into each bottle, thereby upholding quality standards.

3. **Seamless Capping and Labeling:** This packaging line seamlessly integrates capping and labeling modules, providing a complete packaging solution. By automating these stages, manufacturers can achieve a higher production rate, enhanced efficiency, and reduced labor costs.

4. **Flexible and Customizable:** INLINE FILLING SYSTEMS understands that each distillery has unique requirements. Hence, their packaging line offers flexibility and customization options, allowing manufacturers to tailor the system to their specific needs. This adaptability ensures optimal performance and adaptability to evolving market demands.

**Case Study Style**

To better understand the impact of automatic packing lines in the distillery industry, let’s explore a case study featuring a prominent distillery that implemented the DISTILLERS SEMI AUTOMATIC PACKAGING LINE.

*XYZ Distillery*, an award-winning producer of premium spirits, was facing significant challenges in meeting the escalating demand for their products. Their existing packaging process relied heavily on manual labor, leading to human errors, inconsistent output, and an inability to scale production effectively.

Upon adopting the DISTILLERS SEMI AUTOMATIC PACKAGING LINE from INLINE FILLING SYSTEMS, XYZ Distillery witnessed remarkable improvements. The automated bottle feeding mechanism reduced loading time by 40%, while the accurate filling mechanism ensured each bottle contained the precise volume of liquid. The integration of capping and labeling modules further streamlined the process, resulting in a 30% increase in production efficiency.

In addition to the immediate benefits, XYZ Distillery appreciated the customizable nature of the packaging line. The ability to adjust the system according to their unique bottle sizes and labeling requirements provided them with a competitive edge.

**Conclusion**

Automatic packing line manufacturers have emerged as key players in meeting the ever-growing demands of the packaging industry. INLINE FILLING SYSTEMS, with their DISTILLERS SEMI AUTOMATIC PACKAGING LINE, has empowered distilleries to enhance operational efficiency, ensure product consistency, and drive business growth. As the packaging landscape continues to evolve, the incorporation of advanced technologies such as automatic packing lines will undoubtedly play a pivotal role in shaping the future of packaging processes.

Automatic Packing Line

“Efficient and Cutting-Edge Packaging Solutions for Distillers: Discover the Inline Filling Systems from Top Manufacturers”