Project Spotlight: Tilt Pour Permanent Mold for A206 High Strength Aluminum

Introduction:

This video showcases the efficiency and innovation involved in the Tilt Pour Permanent Mold for A206 High Strength Aluminum. It displays the importance of having a mold that can withstand high-temperature applications like aluminum casting. The video is informative and provides viewers with key insights into the manufacturing process.

Project Spotlight - A206 Alum. Complex Tilt Pour Mold:

Anderson Global demonstrates extensive experience in both design and manufacturing. They aim to improve the techniques and technology used in the manufacture of complex molds. Their expertise is showcased in the Tilt Pour Permanent Mold for A206 High Strength Aluminum, which is setting new standards in efficiency and effectiveness.

Key features:

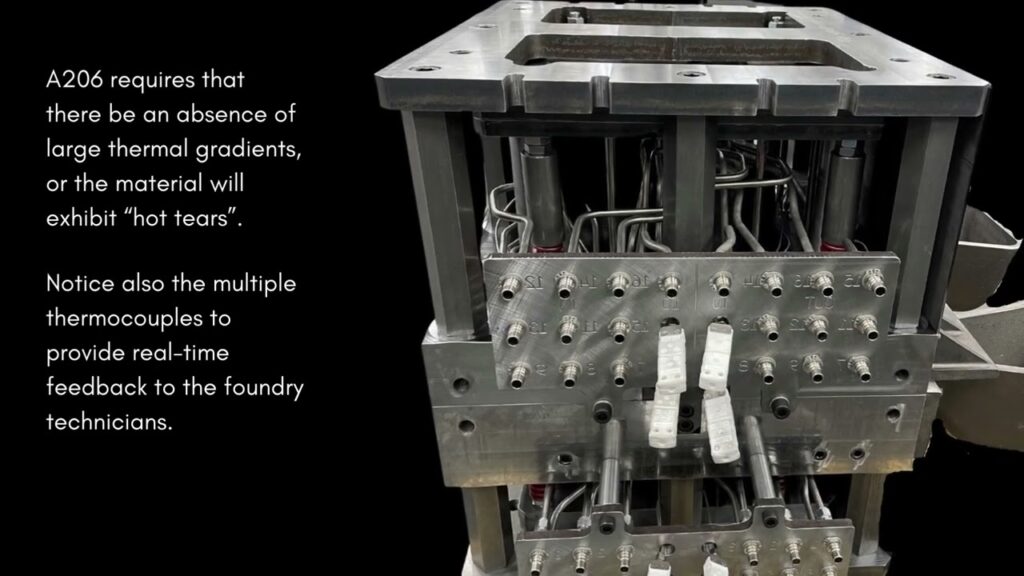

The uniqueness of the Tilt Pour Permanent Mold for A206 High Strength Aluminum lies in its design, which includes a specialized tilt and pour system. This system allows for greater consistency in the casts, waste minimization, and a reduction in reworks. The mold can create complex geometries, which was previously not attainable in permanent molds. The mold's ability to withstand high-temperature applications makes it a perfect fit for A206 High Strength Aluminum casting.

Video content:

The video details the advancements in the mold manufacturing process and highlights the key features of the Tilt Pour Permanent Mold. It showcases the manufacturing process from design to the production phase, giving an overview of the equipment and techniques used. The video also demonstrates the high-quality results of the final casting.

Tags and keywords:

The Tilt Pour Permanent Mold, A206 High Strength Aluminum, mold manufacturing process, design, production phase, equipment, techniques, and key features.

Hashtags:

#TiltPourPermanentMold #A206HighStrengthAluminum #MoldManufacturingProcess #Design #ProductionPhase #Equipment #Techniques #KeyFeatures

Conclusion:

The Tilt Pour Permanent Mold for A206 High Strength Aluminum is a game-changer in the casting industry. Anderson Global's expertise and innovation have led to a mold that provides consistent results, waste minimization and reduction in reworks, and the ability to create complex geometries. This video showcases the mold's unique features and demonstrates the efficiency and effectiveness of the manufacturing process.