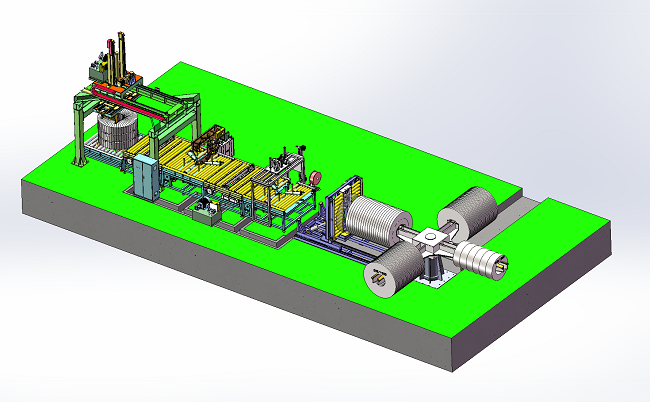

Key Components of the Slitting Coil Handling and Packing Line:

- Coil Down Ender System

This system adeptly lifts and transfers bare coils from a turnstile to a conveyor. It includes a hydraulic station, a coil lifter, and a conveyor, which work together to ensure smooth and efficient handling of the coils from start to finish. - Automated Steel Coil Strapping Machine

Designed for eye-through strapping, this PET strapping machine can handle steel coils by elevating and rotating them 360 degrees. It offers the ability to apply 3, 4, or 6 straps, providing precise and secure strapping that enhances the efficiency and consistency of the packaging process. - Automatic Slit Coil Packing Machine

This machine is tailored for wrapping steel coils with paper and stretch film through the coil’s eye. It automates the packaging process, securely and efficiently wrapping the coils to ensure they are well-protected during handling and transport. - Centering Station

Equipped with a roller conveyor and a lifting table, the Centering Station efficiently guides and centers steel coils. It uses sensors to detect the coil’s approach, lifting it from the conveyor and employing a centering pushing mechanism to align it perfectly with the conveyor’s center for precise processing in subsequent stages. - Slitting Coil Stacking Machine

This advanced machine transfers packed coils from the centering conveyor to pallets individually, significantly reducing the need for manual labor and enhancing workplace safety. It includes the manual insertion of timber separators between coils to ensure stable and secure stacking, preventing damage during transportation.