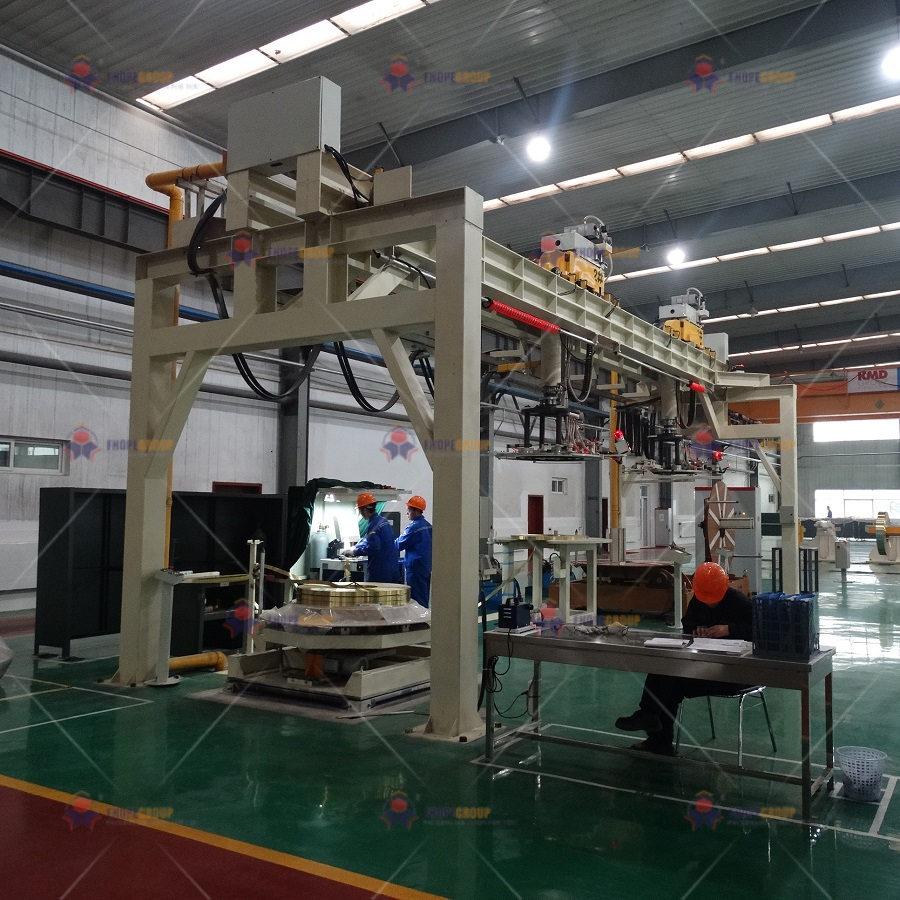

The welding line has the operation process, including:

- Handling devices, including cranes, forklifts, and conveyors, are utilized to transfer copper coils across various stations within the welding line.

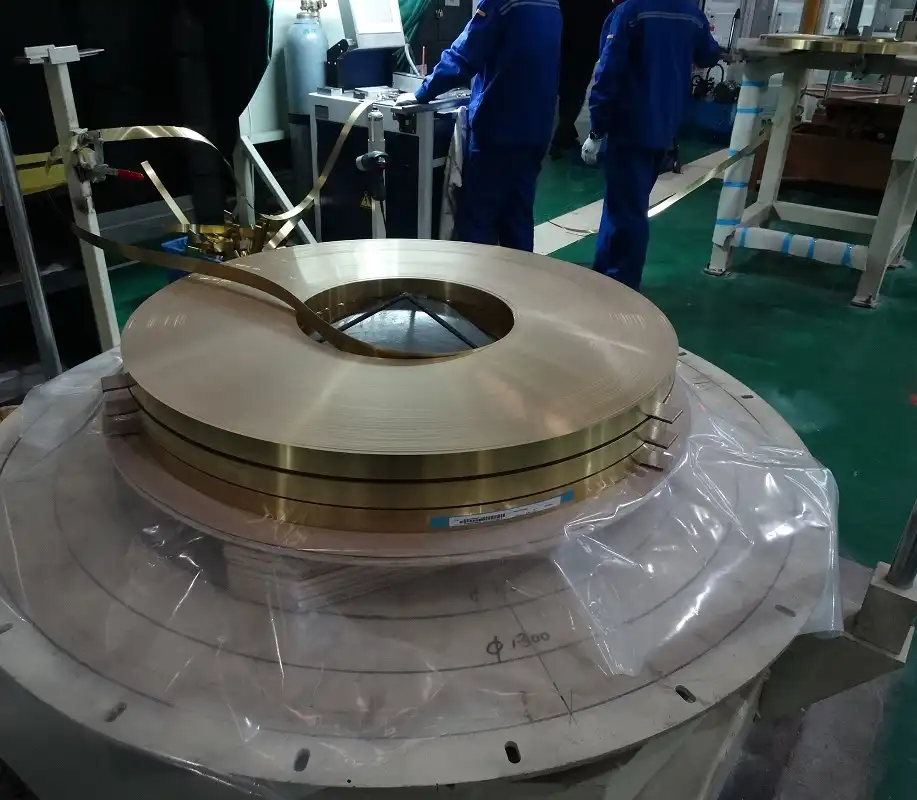

- A coil upender is employed to rotate the coils from a horizontal to a vertical orientation or vice versa.

- A transit platform facilitates the movement of coils through different phases of the welding process.

- The welding operation might involve either a robotic arm or manually operated welding equipment, depending on the welding technique utilized.

- A rotate-lifter platform is available to adjust the position of the coils, enabling welding from multiple angles to achieve uniform and superior quality welds.

Main features of the welding line:

Equipment Coordination: Each piece of equipment is meticulously aligned along the same axis to ensure a smooth and efficient transfer of copper coils through each stage of the welding process.

Alternating Upenders: Incorporating two upenders that operate alternately enhances the versatility and adaptability of the welding line. This feature is especially beneficial for handling various types of copper coils and accommodating fluctuations in production volumes.

Vacuum Chuck Integration: Integrated throughout the welding line, vacuum chucks help to minimize manual handling of the copper coils, ensuring accurate placement and stability during the welding process.

Rotate-Lifter Functionality: The inclusion of a rotate-lifter platform ensures proper positioning of the copper coils, which contributes to the consistency and quality of the welds.

Accessibility and Maintenance: Strategic gaps in the transit platform provide easy access to the lower parts of the welding line. This design consideration simplifies maintenance and repair activities, enhancing operational convenience.