The Evolution of Industrial Automation Robots: A Game-Changer in Palletizing Systems

Industrial automation has revolutionized countless industries, streamlining processes, improving efficiency, and boosting productivity. One key area where automation has made tremendous strides is in palletizing systems. Robots have become increasingly prevalent in this field, transforming the way presentation boards, and various other products are stacked and organized.

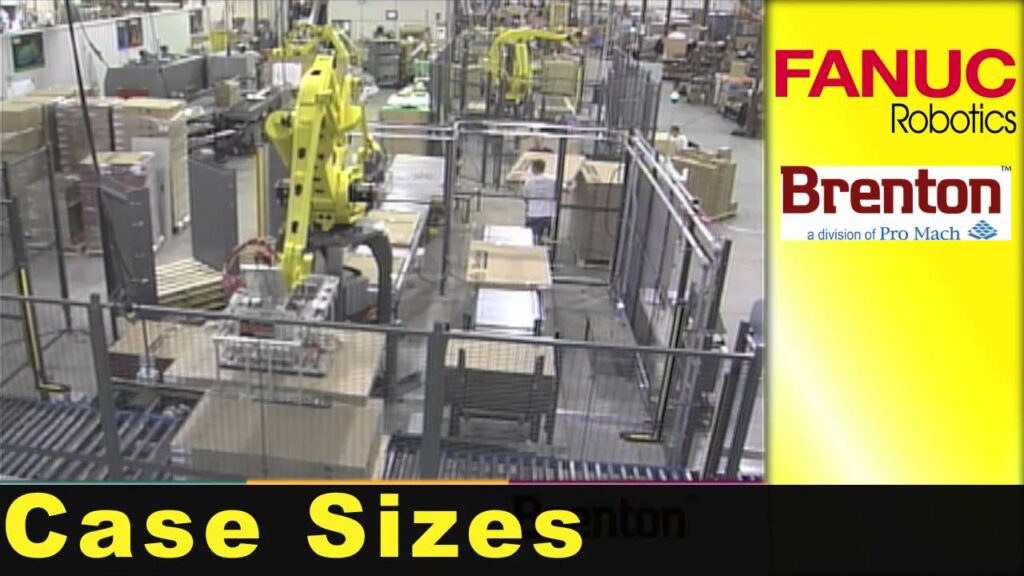

In recent years, the introduction of the FANUC M-410iB robot has taken the palletizing industry by storm. This innovative system has brought unprecedented speed, accuracy, and flexibility to the world of palletizing, enhancing productivity for businesses worldwide. Let us delve deeper into the fascinating world of industrial automation robots and explore the remarkable capabilities of the FANUC M-410iB robot.

Industrial automation robots have evolved from simple mechanical arms, capable of repetitive tasks, to advanced machines with artificial intelligence, sophisticated software, and enhanced sensory capabilities. These robots can now perform complex operations with remarkable precision, effortlessly adapting to different product sizes, shapes, and weights.

The FANUC M-410iB robot is a shining example of the technological advancements in the field of industrial automation. Equipped with advanced vision systems, this robot can precisely track and locate presentation boards on a conveyor belt, ensuring accurate palletizing every time. The robot's state-of-the-art sensors detect any misalignment or irregularity in the boards, making necessary adjustments in real-time, preventing potential damage to the products.

What sets the FANUC M-410iB robot apart from its counterparts is its exceptional speed and efficiency. This robot is capable of palletizing presentation boards at an impressive rate, significantly reducing production time and costs. With its rapid movements and high payload capacity, the robot can handle multiple boards simultaneously, enabling businesses to meet tight deadlines while maintaining optimal quality standards.

Furthermore, the FANUC M-410iB robot offers unparalleled flexibility in palletizing operations. Its versatile gripper system allows the robot to handle presentation boards of various sizes, stacking them in precise configurations. This flexibility is crucial for businesses that deal with a wide range of products, eliminating the need for manual adjustment and reducing downtime between different palletizing tasks.

Implementing industrial automation robots in palletizing systems offers numerous advantages for businesses. Firstly, these robots ensure consistent and precise palletizing, eliminating human errors that can lead to product damage or misplacement. This reliability translates into higher customer satisfaction and reduced waste, boosting overall profitability.

Moreover, utilizing the FANUC M-410iB robot in palletizing operations enhances workplace safety. The robot's advanced safety features, such as collision detection and emergency stop mechanisms, minimize the risk of accidents and injuries, creating a safer working environment for employees. This, in turn, reduces insurance costs and improves employee morale and retention.

The impact of industrial automation robots on overall productivity cannot be overstated. By automating palletizing processes, businesses can significantly increase their output, meeting growing customer demands with ease. This improved productivity enables companies to scale their operations and expand their market reach, driving revenue growth and fostering long-term sustainability.

While the adoption of industrial automation robots in palletizing systems is undoubtedly a game-changer, it is essential to note that this innovation does not render human labor redundant. Instead, it allows workers to focus on more complex and value-added tasks, such as quality control, strategic decision-making, and process optimization. Ultimately, this synergy between human expertise and robotic efficiency leads to improved overall performance and competitiveness.

In conclusion, the introduction of the FANUC M-410iB robot has revolutionized palletizing systems, particularly in the field of presentation board manufacturing. This remarkable industrial automation robot showcases the immense potential of modern robotics in streamlining processes, enhancing productivity, and improving workplace safety. As businesses continue to embrace automation, the future of palletizing systems looks brighter than ever, with more sophisticated robots pushing the boundaries of what is possible in industrial automation.

Industrial Robot

"Palletizing Presentation Boards with Advanced Industrial Automation Robots"