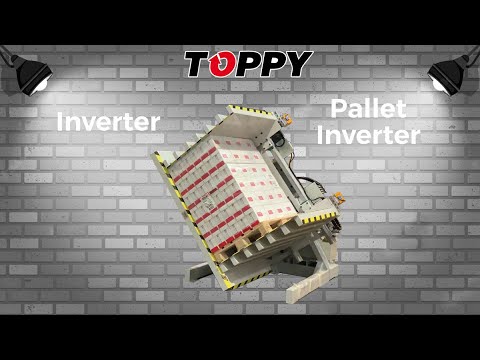

TOPPY (Pallet Inverter – Pallet changer -): Everything You Need to Know

If you are looking to improve your warehouse’s productivity and streamline your pallet handling operations, you may want to consider investing in a pallet changer machine like TOPPY. TOPPY (Pallet Inverter – Pallet changer -) is a leading brand in the industry, offering a range of high-quality, efficient, and customizable pallet inverters and changers suitable for various applications.

Who Needs a Pallet Changer Machine?

If pallet handling is a crucial part of your business operations, you may need a pallet changer machine like TOPPY to automate the process and save time, labor costs, and material damage. TOPPY’s pallet changers and inverters have been designed to handle various types of pallets and loads, including fragile, heavy, or oddly shaped ones, and can rotate or invert them safely and efficiently without manual intervention.

Some of the industries and businesses that can benefit from using TOPPY’s pallet changers are:

– Food and beverage industry

– Pharmaceutical and chemical industry

– Logistics and transportation

– Manufacturing and packaging

– Recycling and waste management

How Can TOPPY’s Pallet Changer Machines Improve Your Operations?

TOPPY’s pallet changers and inverters offer several benefits to optimize your pallet handling process and enhance your warehouse’s efficiency, such as:

– Reduce labor costs: With TOPPY’s pallet changers, you can automate your pallet handling process and save on manual labor costs. The machines can handle multiple pallets simultaneously and rotate or invert them in seconds, freeing up your staff’s time and minimizing the risk of injuries or accidents.

– Prevent material damage: When pallets are rotated or inverted manually, there is a high risk of material damage or product spillage. With TOPPY’s pallet changers, you can avoid these risks and ensure your products’ quality and integrity. The machines can handle delicate or heavy loads with care and precision, and the adjustable clamps and grips can adapt to any pallet size or shape.

– Improve safety and ergonomics: Manual pallet handling can be a physically demanding and risky task, leading to musculoskeletal disorders and injuries. With TOPPY’s pallet changers, you can improve your staff’s safety and ergonomics by reducing the need for manual handling and repetitive motions. The machines can also be customized to fit your specific ergonomic requirements and reduce operator fatigue.

– Increase productivity and throughput: By automating your pallet handling process with TOPPY’s pallet changers, you can speed up your operations and increase your throughput. The machines can handle up to 30 pallets per hour, depending on the model and configuration, and can integrate with your existing conveyor systems or forklifts seamlessly. This way, you can optimize your workflow, minimize downtime, and meet your customers’ demands faster.

Conclusion

In summary, if you’re looking for a reliable, customizable, and efficient solution to improve your pallet handling process and increase your productivity, TOPPY’s pallet changers and inverters are worth considering. With their innovative technology, superior quality, and excellent customer support, TOPPY can help you choose the right machine for your needs and provide you with a complete solution to enhance your warehouse’s performance. For more information or to request a quote, contact TOPPY at info@toppy.it or visit their website at https://www.toppy.it/.