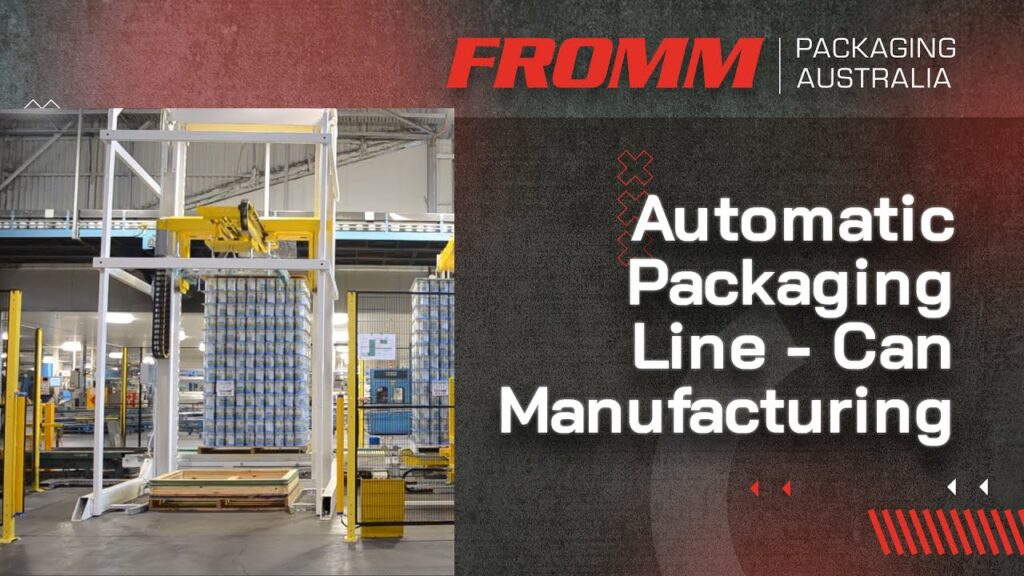

Title: Automatic Packaging Line – Can Manufacturing

Introduction:

This video provides an in-depth overview of the automatic packaging line used in the can manufacturing industry. It highlights the main features of the line and provides valuable insights into its functionality.

Video Content:

The video begins by introducing the automatic packaging line and how it is used in can manufacturing. It explains how the line helps to streamline the packaging process, saving time and increasing efficiency. The video then goes on to explore the various components of the line, including the can filler, seamer, conveyor system, and inspection equipment.

One of the main benefits of the automatic packaging line is its ability to handle a wide range of can sizes and shapes, making it a versatile solution for can manufacturers. The line also has advanced safety features and quality control measures built in, ensuring that all products are packaged to the highest standards.

FROMM Packaging Australia has been at the forefront of engineering and manufacturing high-quality strapping and wrapping solutions for over 70 years. With their expertise and experience, they have designed an automatic packaging line that meets the demands of the can manufacturing industry.

In summary, this video provides a comprehensive overview of the automatic packaging line used in can manufacturing. It highlights the key benefits of the line and explores its various components in detail. With its advanced safety features and quality control measures, it is a versatile solution for can manufacturers looking to streamline their packaging process.

Tags and Keywords:

Automatic Packaging Line, Can Manufacturing, FROMM Packaging Australia, Strapping Solutions, Wrapping Solutions, Conveyor System, Quality Control, Safety Features, Efficiency, Versatile Solution.

Hashtags:

#AutomaticPackagingLine #CanManufacturing #FROMMPackagingAustralia #StrappingSolutions #WrappingSolutions #Efficiency #SafetyFeatures #QualityControl #VersatileSolution