Types of Industrial Robots: A Comprehensive Review of Selection Criteria

Industrial robots have revolutionized the manufacturing industry by automating various tasks and improving efficiency. With advancements in technology, the market is flooded with different types of industrial robots, each catering to specific needs and requirements. However, selecting the right robot for your business can be a daunting task. In this article, we will delve into the important selection criteria for industrial robots, ensuring that you make an informed decision.

Before we dive into the selection criteria, let’s first understand the different types of industrial robots available in the market. These robots can be categorized into six main types based on their functionality and application:

1. Articulated Robots:

– These robots have rotary joints and are known for their flexibility and range of motion.

– Suitable for assembly tasks, material handling, and arc welding.

2. Cartesian Robots:

– Also known as gantry or rectilinear robots, they operate on three linear axes.

– Perfect for tasks that require heavy lifting, pick-and-place operations, and 3D printing.

3. SCARA Robots:

– SCARA stands for Selective Compliance Assembly Robot Arm. These robots have rigid arms with a prismatic joint for vertical movement.

– Ideal for tasks that demand high-speed and precision, such as assembly and pick-and-place operations.

4. Delta Robots:

– Known for their speed and accuracy, delta robots have a parallel linkage configuration.

– Commonly used in the food and beverage industry for packaging and sorting applications.

5. Collaborative Robots (Cobots):

– Cobots are designed to work alongside humans safely and efficiently.

– They are suitable for tasks such as assembly, quality control, and material handling.

6. Mobile Robots:

– These robots are equipped with wheels or tracks and can move autonomously.

– Widely used in logistics, warehousing, and inventory management.

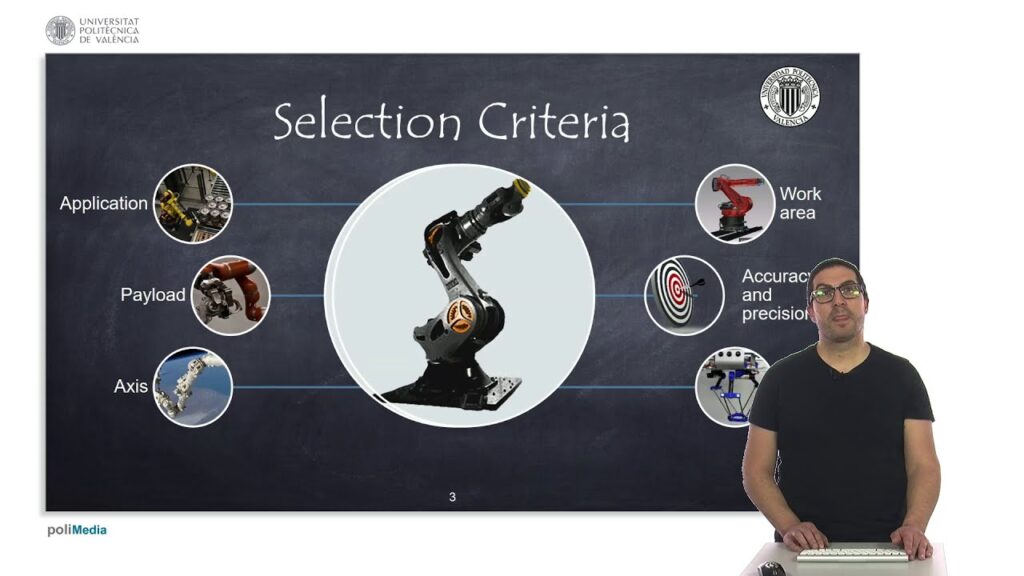

Now that we have familiarized ourselves with the types of industrial robots, let’s explore the selection criteria that play a crucial role in choosing the right robot for your business:

1. Payload Capacity:

– Assess the weight of the objects that the robot will handle and select a robot with an appropriate payload capacity.

– Overloading the robot can lead to decreased efficiency and potential damage.

2. Reach and Workspace:

– Consider the dimensions of the workspace and the reach required to perform the intended tasks.

– A robot with a suitable reach ensures maximum utilization of space and efficient operation.

3. Accuracy and Repeatability:

– Accuracy refers to the ability of the robot to perform a task precisely, while repeatability measures its consistency in recreating the same task.

– Evaluate the required level of accuracy and repeatability for your application to avoid any quality control issues.

4. Speed and Cycle Time:

– The speed of the robot directly impacts the cycle time and overall productivity.

– Analyze the desired production rate and select a robot with an appropriate speed to meet your requirements.

5. Programming and Integration:

– Evaluate the ease of programming and integration of the robot into your existing systems.

– User-friendly programming interfaces and compatibility with different software platforms are crucial for seamless operation.

6. Safety Features:

– Depending on the application and the presence of human workers, consider the safety features required for the robot.

– Collaborative robots, for example, are specifically designed with multiple safety features to prevent accidents.

7. Cost and Return on Investment (ROI):

– Assess the initial cost of the robot, installation, and maintenance expenses, and estimate the expected return on investment.

– While cost is an important consideration, it should be weighed against the potential efficiency gains and improved productivity.

In conclusion, selecting the right industrial robot for your business requires careful consideration of various criteria. Understand the different types of industrial robots available and assess the selection criteria such as payload capacity, reach, accuracy, speed, programming, safety features, and cost. By aligning your requirements with the capabilities of the robot, you can ensure optimal performance and maximize your return on investment.

References:

– [Types of Industrial Robots](https://www.robotics.org/blog-article.cfm/What-are-the-Typical-Types-of-Industrial-Robots/172)

– [Selection Criteria for Industrial Robots](https://www.robotics.org/robotics/types-of-industrial-robots)

Industrial Robot

“Exploring Criteria for Industrial Robot Selection & Types of Robotic Systems in Manufacturing”