# Upender Handling Machine for Mold with Fixture: Revolutionizing Mold Handling Efficiency

**Introduction**

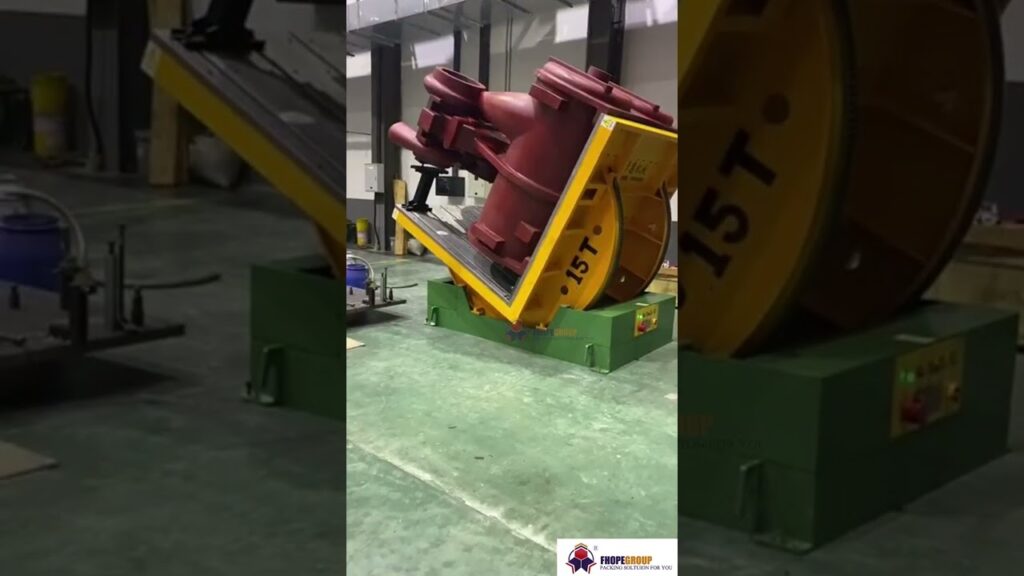

In this video, we delve into the world of mold handling, presenting the remarkable capabilities of the Upender Handling Machine for mold with fixture. Discover how this cutting-edge machine revolutionizes the mold handling process, ensuring maximum efficiency and productivity. Say goodbye to cumbersome manual operations and embrace a new era of seamless and streamlined mold handling.

**Video Content**

With the Upender Handling Machine for mold with fixture, your mold handling tasks will never be the same again. Here are the key highlights and fascinating facts about this innovative equipment:

1. Enhanced Efficiency: This state-of-the-art machine eliminates the cumbersome manual efforts required for mold handling. By automating the process, it significantly reduces operational time and boosts overall efficiency, allowing you to focus on other critical tasks.

2. Precise Positioning: One of the standout features of this upender is its ability to precisely position molds in the desired orientation. Its advanced fixture mechanism ensures accurate alignment, optimizing subsequent manufacturing processes and minimizing errors.

3. Load Capacity and Flexibility: The Upender Handling Machine is designed to handle molds of varying sizes and weights, ensuring unparalleled adaptability. Whether your molds are small or large, this versatile machine can handle them with ease, providing the utmost convenience in your operations.

4. Safety and Stability: Ensuring the safety of your molds is paramount, and this machine incorporates robust safety features to provide a secure handling environment. From anti-slip mechanisms to stabilizing components, it guarantees the protection and integrity of your valuable molds.

5. Seamless Integration: The Upender Handling Machine can be seamlessly integrated into your existing mold handling setup. Its user-friendly interface and intuitive controls make it easy to operate, eliminating the need for extensive training or complex installation processes.

6. Time and Cost Savings: By significantly reducing manual labor, streamlining workflows, and minimizing errors, this machine offers substantial time and cost savings. It optimizes your overall mold handling process, leading to enhanced productivity and profitability.

**Conclusion**

Witness the revolution in mold handling efficiency with the Upender Handling Machine for mold with fixture. Embrace the advantages of automation and experience the ultimate convenience, precision, and productivity in your mold handling operations. Say goodbye to inefficiencies and hello to seamless, optimized processes that propel your business towards greater success.

For more information and inquiries, please visit our website or contact us via email: info@fhopepack.com. Join the mold handling revolution today!

**Tags and Keywords**: upender handling machine, mold handling efficiency, automated mold handling, precise mold positioning, mold handling equipment, seamless integration, time and cost savings, mold handling revolution

**Hashtags**: #moldhandling #efficiencyrevolution #automatedequipment #precisionhandling #seamlessintegration #timesavings #costsavings

Mold Upender

"Compact Mold Fixture Handling Machine by Upender for Efficient Handling"