Description:

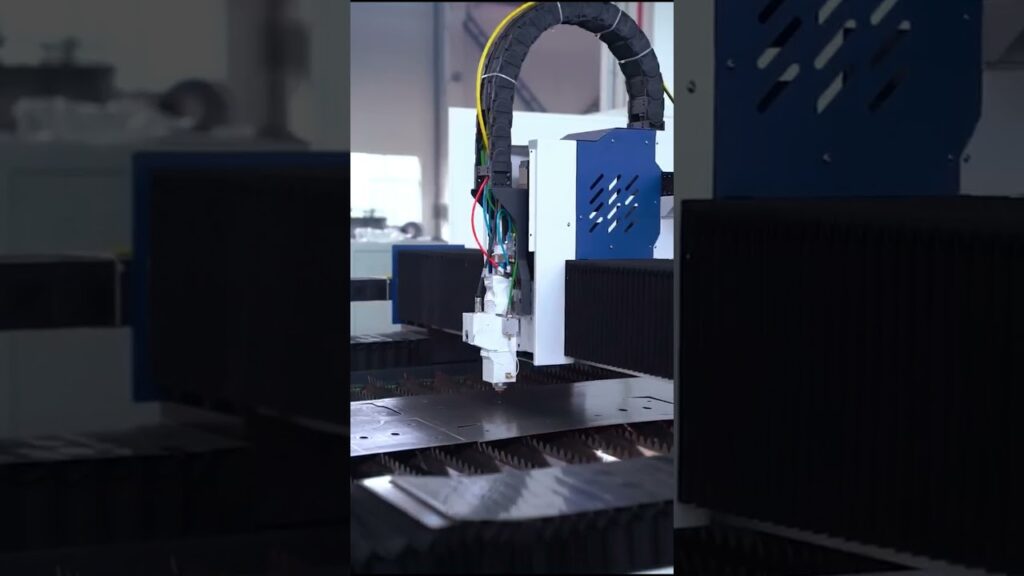

Coil Fed Laser Cutting Machine - The Perfect Solution for Precision Cutting

Coil fed laser cutting machines have revolutionized the manufacturing industry, enabling impeccable precision and efficiency in cutting various materials. This article explores the exceptional capabilities of coil fed laser cutting machines, highlighting their key features and benefits. With advanced laser technology and a seamless coil feeding system, these machines offer a superior cutting experience.

Overview

In this video, we delve into the world of coil fed laser cutting machines, exploring their remarkable capabilities and applications. From automotive and aerospace industries to signage and metal fabrication, these machines have proven their worth by delivering outstanding results.

Key Features

These cutting-edge machines are equipped with state-of-the-art features that set them apart from traditional cutting methods. Some key features include:

1. Advanced Laser Technology: The coil fed laser cutting machines utilize the latest laser technology, ensuring precision and accuracy in every cut.

2. Seamless Coil Feed System: The automated coil feed system allows for continuous and uninterrupted cutting, eliminating the need for manual reloads and significantly reducing production time.

3. Versatile Material Compatibility: With the ability to cut various materials such as stainless steel, aluminum, and even non-ferrous metals, these machines offer versatility and adaptability.

4. Precise and Clean Cuts: The high-powered laser ensures clean and precise cuts, minimizing material waste and maximizing efficiency.

5. Speed and Efficiency: With rapid cutting speed and efficient material utilization, coil fed laser cutting machines enhance productivity and optimize workflow.

Benefits

Investing in a coil fed laser cutting machine provides numerous benefits for manufacturers and fabricators. Some notable advantages include:

1. Enhanced Productivity: The automated coil feed system and swift cutting speed boost productivity, enabling manufacturers to meet tight deadlines and handle high-volume projects.

2. Cost Effectiveness: The precise cutting capabilities reduce material waste, resulting in cost savings and improved profitability.

3. Superior Cutting Quality: The clean and precise cuts achieved by coil fed laser cutting machines ensure high-quality end products, meeting the most demanding standards.

4. Flexibility and Adaptability: These machines can handle a wide range of materials and thicknesses, offering flexibility in various applications.

5. Streamlined Workflow: The automated process eliminates manual interventions, streamlining the entire cutting operation for increased efficiency.

In conclusion, coil fed laser cutting machines are a game-changer in the manufacturing industry, providing unparalleled precision, speed, and efficiency. Whether the requirement is for intricate designs or high-volume productions, these machines deliver exceptional results. Explore the vast possibilities and experience the future of precision cutting with coil fed laser cutting machines.

Tags: coil fed laser cutting machine, precision cutting, laser technology, automated coil feed system, material compatibility, clean cuts, productivity, cost effectiveness, cutting quality, flexibility, streamlined workflow

Hashtags: #coilfedlasercuttingmachine #precisioncutting #lasertechnology #manufacturingindustry