Title: Toppy’s L-Shape Inline Pallet Inverter – Faster & More Efficient Than Ever!

Description:

Introduction:

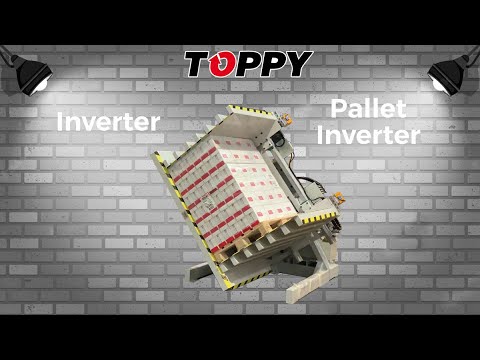

Toppy’s L-Shape Inline Pallet Inverter is a fully automatic pallet exchange system that revolutionizes your material handling process. If you’re tired of slow, manual pallet exchange systems, try Toppy’s latest innovation and see how it can improve your production line dramatically.

Video Content:

Toppy’s L-Shape Inline Pallet Inverter is designed to replace your manual pallet exchange process with a fully automatic system that takes only seconds to complete. The system is designed to interface with your conveyor belt, meaning there’s no need for manual pallet transfers. With its compact, modular design, the L-Shape Inline Pallet Inverter can be easily integrated into any production line.

The L-Shape Inline Pallet Inverter can handle any size or weight of pallets efficiently and safely, preventing damage to products or pallets. Once activated, the system quickly separates the load from its original pallet and transfers it to a new pallet using a unique pivot mechanism.

With its advanced control system, the L-Shape Inline Pallet Inverter ensures maximum throughput, reducing downtime and increasing efficiency. The system is also easy to use, with minimal training required to operate.

So if you’re looking for a faster, more efficient, and reliable pallet exchange system, try Toppy’s L-Shape Inline Pallet Inverter today!

Tags and Keywords:

Inline Pallet Inverter, Toppy, L-Shape, Material Handling, Automatic Pallet Exchange, Conveyor Belt Integration, Highly Efficient, Advanced Control System, Reduced Downtime, Increased Efficiency, Reliable

Hashtags:

#InlinePalletInverter #Toppy #LShape #MaterialHandling #AutomatedSystems #Efficiency #Reliability #Productivity #ConveyorBeltIntegration #AdvancedControlSystem