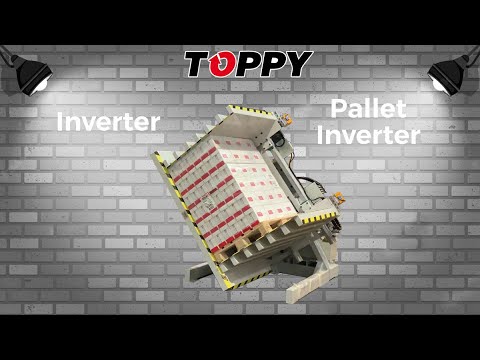

Title: Pallet Inverter – Revolutionizing the Loading and Unloading Process

Introduction: In this video, we explore the innovative technology of pallet inverters and how they are revolutionizing the loading and unloading process of pallets. Whether you’re in the manufacturing industry, logistics or distribution center, this video will unveil the benefits of pallet inverters and how they can enhance the efficiency and productivity of your operations.

Video Content:

H2 Bold Title: What is a Pallet Inverter?

A pallet inverter is a machine that can flip pallet loads of products and materials upside down. It is designed to lift and rotate entire loads without having to manually or manually remove the contents on the pallet. Pallet inverters can efficiently extract products or materials that have shifted, spilled, or collapsed during transportation, making it easier to restack or repackage them onto new pallets. The invention of pallet inverters has allowed manufacturers to minimize product damage during loading and unloading, which can save them a significant amount of time and money.

H2 Bold Title: The Benefits of Using Pallet Inverters

Pallet inverters offer a wide range of benefits, including:

1. Increased efficiency – Pallet inverters can unload, invert, and reload pallets in a matter of minutes, allowing businesses to speed up their loading and unloading process.

2. Reduced labor costs – Instead of manually unloading and reloading pallets, pallet inverters can complete the task with minimal human intervention, reducing labor costs.

3. Improved safety – Pallet inverters can prevent the risk of injuries and damages caused by manual labor.

4. Reduced product damage – Pallet inverters can minimize the risk of product damage during loading and unloading, ensuring quality products for customers.

5. Enhanced flexibility – Pallet inverters can accommodate a wide range of pallet sizes and loads.

H2 Bold Title: Applications of Pallet Inverters

Pallet inverters can be used across a range of industries, including:

1. Food and beverage – Pallet inverters can be used to safely and efficiently unload and reload food and beverage products, such as cans, bottles, and jars.

2. Chemicals – Pallet inverters can unload and reload drums or barrels of chemicals easily and safely.

3. Pharmaceuticals – Pallet inverters can be used in the pharma industry to help deal with product spillages, usually powder applications.

4. Manufacturing – Pallet inverters can help manufacturers unload and reload products easily without manually removing products.

5. Logistics and distribution centers – Pallet inverters are widely used in distribution centers and logistics warehouses to quickly unload and reload pallets.

Conclusion:

In summary, pallet inverters offer a range of benefits across different industries. They can help increase efficiency, reduce labor costs, improve safety, reduce product damage, and enhance flexibility. The invention of pallet inverters has revolutionized the loading and unloading process, making it more efficient and productive. If you want to learn more about pallet inverters, visit our website for comprehensive information about this innovative technology.

Tags and Keywords: Pallet Inverter, loading and unloading process, manufacturing industry, logistics, distribution center, reduce product damage, improved efficiency, reduced labor costs.

Hashtags: #PalletInverter #LoadingUnloading #ManufacturingIndustry #Logistics #DistributionCenter #Efficiency #Productivity #ReduceProductDamage #ReducedLaborCosts