Robots have come a long way from being mere machines programmed to perform specific tasks. With advancements in technology, we now have robots that can mimic human movements and interact with their surroundings. One such remarkable creation is Meet Dog-E, a robot dog developed by WowWee. Dog-E is equipped with life-like movements, audio sensors, and touch sensors, making it a truly remarkable robot companion.

In the world of industrial manufacturing, robots have revolutionized the way tasks are carried out. From assembly lines to logistics, these machines have managed to streamline processes and increase efficiency. Industrial robots are designed to handle repetitive and physically demanding tasks, freeing up human workers to focus on more complex and creative endeavors. With the rapid advancement of technology, we are witnessing a new era of automation in manufacturing.

Dog-E, created by WowWee, showcases the potential of robotics in the manufacturing industry. This robot dog possesses an impressive range of features that mimic the movements and behaviors of a real dog. From wagging its tail to responding to touch, Dog-E can make its presence felt in a way that no other robot can.

One of the key features of Dog-E is its audio sensors, which enable it to hear sounds and respond accordingly. This is particularly useful in a manufacturing setting, where machines need to react to different auditory cues. For example, if there is a sudden loud noise in the factory, Dog-E can detect it and respond in a manner similar to a real dog. This not only adds a touch of realism but also enhances the overall safety of the workspace.

The touch sensors on Dog-E's head, nose, and body are another noteworthy feature. These sensors enable the robot dog to respond to physical interactions, just like a real dog would. This can be incredibly useful in manufacturing environments, where human workers need to interact with robots regularly. The touch sensors allow for a more natural and intuitive interaction, making the robot an effective and user-friendly tool.

Industrial robots like Dog-E are transforming the manufacturing industry by performing tasks that were once considered suitable only for human workers. These robots are playing a significant role in enhancing efficiency and productivity across different sectors. Whether it's in assembly lines or logistics, robots are proving to be valuable assets, bringing speed, precision, and consistency to various processes.

The use of robots in manufacturing is not a recent phenomenon. In fact, the idea of using machines to automate tasks dates back to the early 1950s. The first industrial robot, Unimate, was introduced in 1961 and was primarily used in the automotive industry. Since then, robots have become more sophisticated and versatile, capable of performing a wide range of tasks with great precision.

But the future of robotics in manufacturing holds even more exciting possibilities. With recent advancements in artificial intelligence and machine learning, robots are becoming smarter and more adaptive. They can now learn from their surroundings and make decisions based on the data they gather. This opens up new avenues for efficiency and productivity in the manufacturing industry.

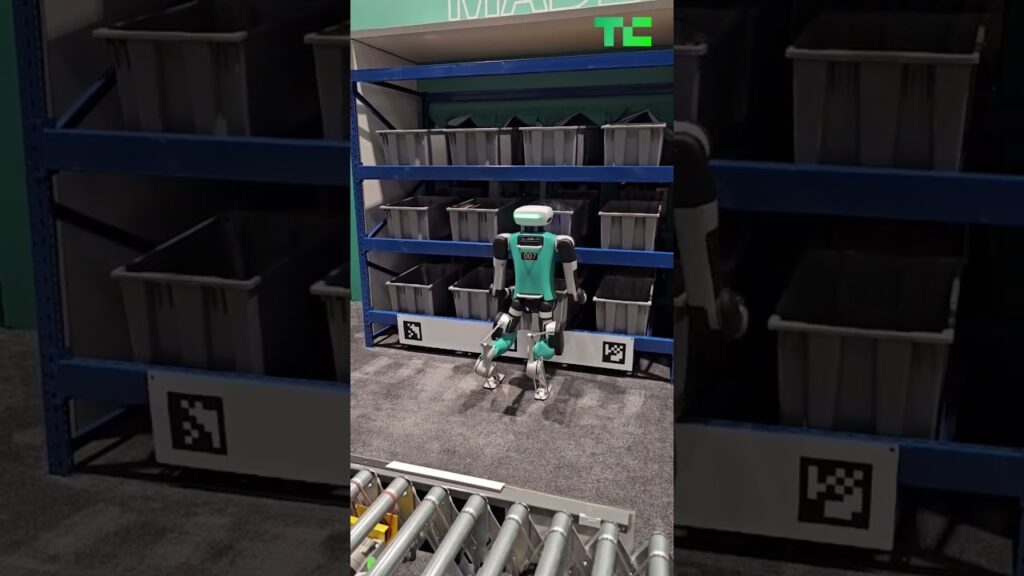

One such example of the future of robotics in manufacturing is Agility Robotics' Digit. Designed for logistics work, Digit is a bipedal robot that can navigate complex environments, handle packages, and even climb stairs. Its advanced capabilities make it an ideal solution for tasks that require both mobility and dexterity.

The integration of robots like Dog-E and Digit into the manufacturing industry is not without challenges. One of the primary concerns is the potential displacement of human workers. As robots take over repetitive and physically demanding tasks, human workers may find themselves in need of new skills and roles. However, it is important to note that the introduction of robots in manufacturing has also created new job opportunities. The need for skilled technicians, engineers, and programmers to maintain and supervise these machines has increased.

In conclusion, the advancements in robotics technology have transformed the manufacturing industry in unimaginable ways. Robots like Dog-E and Digit are pushing the boundaries of what machines can do, making them invaluable tools in various sectors. As we embrace the future of automation, it is crucial to strike a balance between the use of robots and the need for human workers. The collaboration between humans and robots is the key to unlocking the full potential of industrial robotics in manufacturing.

Industrial Robot

"Revolutionizing Logistics: Unveiling Digit, The Cutting-Edge Robot for ProMat 2023 and Industrial Manufacturing"