Automatic Packing and Palletizing Line Revolutionizes Fertilizer Bagging

With the ever-increasing demand for efficient and reliable packaging and palletizing solutions, one company has stepped up to the plate, offering a game-changing innovation in the field of granulated fertilizer bagging. Introducing the Automatic Packing and Palletizing Line, a state-of-the-art system that has revolutionized the way fertilizers are packaged and prepared for shipment.

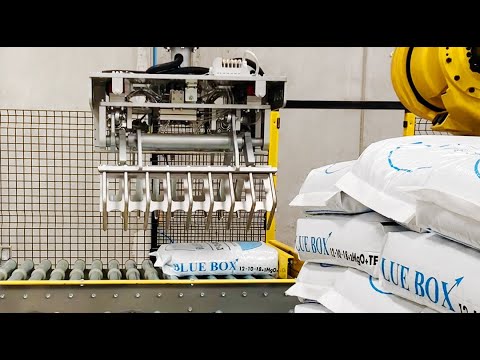

This groundbreaking technology, equipped with robotized palletizing capabilities, boasts a fully automated weighing and bagging line that can process up to an astounding 700 bags per hour. From start to finish, this peering into the future of manufacturing meticulously ensures that each and every bag is filled accurately and efficiently, meeting the highest standards of quality and consistency.

The benefits of this innovative system are undeniable. By automating the bagging and palletizing process, companies can significantly increase their productivity levels while minimizing the risk for human error. This means fewer obstructions in the production line and a smoother workflow overall. Not to mention, the precise weighing mechanism ensures that each bag contains the exact amount of granulated fertilizer, eliminating any chances of under or over-fertilizing. This, in turn, gives farmers and growers the peace of mind that their crops will receive the optimal nutrients for healthy growth.

One particularly impressive feature of this system is its ability to work with PE bags formed from a Tubular Reel. This not only enhances the overall durability of the packaging but also allows for more flexibility in bag size. The versatility of the Automatic Packing and Palletizing Line ensures that it can accommodate various bag dimensions, catering to the specific needs of different customers and markets. No longer bound by rigid bag sizes, manufacturers can now customize their packaging to suit their unique requirements, enhancing product appeal and customer satisfaction.

The integration of robotized palletizing is another game-changer in this industry. Traditionally, the labor-intensive task of palletizing bags has always been a time-consuming and physically demanding process. However, with this innovative system, the burden is lifted off human workers and placed onto intelligent robots that can swiftly and accurately stack bags on pallets. This not only reduces the risk of workplace injuries but also optimizes the use of space, ensuring that each pallet is packed to its maximum capacity.

The Automatic Packing and Palletizing Line also offers an array of additional features that further streamline the bagging process. The integrated conveyor system seamlessly transports the bags from one station to another, eliminating the need for manual handling and minimizing the risk of any mishaps along the way. The intelligent control panel puts all the necessary controls at the operator’s fingertips, allowing for easy monitoring and adjustment of the system parameters. Additionally, the user-friendly interface provides real-time data on production rates, bag weights, and any potential errors or malfunctions, enabling swift action to be taken in case of any issues.

In terms of maintenance and safety, this system sets a new standard in the industry. The user-friendly design allows for easy access to critical components, simplifying routine maintenance tasks and minimizing downtime. The robust construction and adherence to the highest safety standards ensure that the system can withstand the rigors of industrial environments while keeping operators and bystanders safe.

As with any innovative technology, the Automatic Packing and Palletizing Line is poised to disrupt the entire fertilizer packaging industry. Its speed, accuracy, and versatility make it a game-changer in terms of productivity and customer satisfaction. Manufacturers, farmers, and growers can rest assured that their granulated fertilizers will be packaged with the utmost precision and care, ready to provide optimal nutrients to crops. With this revolutionary system, the future of fertilizer bagging has arrived.

In conclusion, the Automatic Packing and Palletizing Line has redefined the fertilizer bagging process, offering an unprecedented level of automation, precision, and flexibility. With the ability to process up to 700 bags per hour and accommodate various bag sizes, this system is a game-changer in the industry. The integration of robotized palletizing further enhances productivity and safety, while the user-friendly interface and maintenance features ensure smooth operation and minimal downtime. The future of fertilizer bagging has arrived, and it is embodied in the Automatic Packing and Palletizing Line.

Automatic Packing Line

“Streamlining Fertilizer Packaging with Advanced Automation: Discover Robotized Palletizing and Automatic Packing Solutions”