Automatic Packing and Palletizing Line: Streamlining Packaging Efficiency

In today's fast-paced world, efficiency is key. Companies across industries are constantly seeking innovative solutions to streamline their operations, particularly when it comes to packaging and palletizing. One such solution that has gained traction in recent years is the Automatic Packing and Palletizing Line.

The Automatic Packing and Palletizing Line is a cutting-edge technology that revolutionizes the packaging process. It is designed to automate the entire packaging and palletizing process, from start to finish, resulting in improved productivity, reduced labor costs, and enhanced operational efficiency.

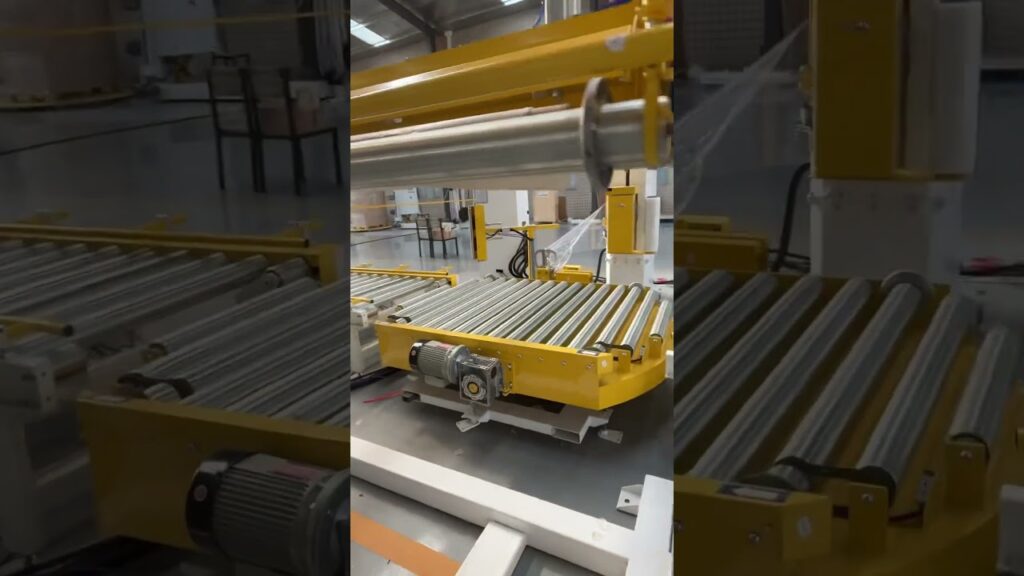

At its core, the Automatic Packing and Palletizing Line consists of three main components: the automatic packing line, pallet dispenser, and palletizer robot. These elements work in harmony to ensure seamless and efficient packaging and palletizing operations.

The automatic packing line is responsible for the careful and precise packaging of goods. It utilizes state-of-the-art technology to efficiently wrap products, ensuring their safety and integrity throughout the transportation process. This automated system eliminates the need for manual intervention, thereby minimizing the risk of human errors and increasing overall productivity.

Adding to the efficiency of the Automatic Packing and Palletizing Line is the pallet dispenser. This component is designed to automatically dispense pallets as needed, eliminating the need for manual handling and reducing downtime. By efficiently supplying pallets to the packaging line, this dispenser ensures a continuous flow of operations, further enhancing productivity and saving valuable time.

Perhaps the most remarkable feature of the Automatic Packing and Palletizing Line is the palletizer robot. This sophisticated robot is equipped with advanced vision systems and precision engineering, enabling it to intelligently stack and arrange products on the pallets. With its flexibility and adaptability, the palletizer robot can handle a wide range of products, sizes, and shapes, ensuring efficient palletization regardless of the required configuration.

To complete the packaging process, an online wrapping machine is often integrated into the Automatic Packing and Palletizing Line. This machine ensures the secure and tight wrapping of the palletized goods, providing stability and protection during transportation and storage. By automating this final step, companies can avoid the inconsistencies and inefficiencies commonly associated with manual wrapping, ensuring a uniform and reliable packaging result.

The benefits of implementing an Automatic Packing and Palletizing Line are manifold. First and foremost, the automation of the entire packaging and palletizing process significantly reduces the reliance on manual labor. This, in turn, lowers labor costs and minimizes the risk of injuries associated with repetitive tasks and heavy lifting.

Moreover, the increased speed and precision achieved through automation result in higher output and improved overall productivity. The Automatic Packing and Palletizing Line can operate around the clock without the need for breaks, ensuring uninterrupted production and quicker turnaround times. This enhanced productivity allows businesses to meet tight deadlines and fulfill customer demands efficiently.

Additionally, the elimination of human intervention reduces the risk of errors and inconsistencies in the packaging process. Automation ensures that products are consistently and accurately packaged, reducing the likelihood of damages during transit. This not only saves costs associated with product replacements but also enhances customer satisfaction by delivering goods in pristine condition.

In conclusion, the implementation of an Automatic Packing and Palletizing Line offers a myriad of benefits for businesses in terms of streamlining packaging operations and improving overall efficiency. The integration of automated packing, pallet dispenser, palletizer robot, and online wrapping machine ensures a seamless and effective packaging process, resulting in increased speed, enhanced precision, and reduced labor costs.

As companies continue to strive for greater efficiency and productivity, the Automatic Packing and Palletizing Line stands as a game-changer in the packaging industry. With its ability to automate and optimize the packaging and palletizing process, this innovative technology is set to revolutionize the way businesses handle their operations. Embracing automation is not just a step forward, but a leap into the future of efficient packaging.

Automatic Packing Line

"Efficient Automation Solutions: Streamline Your Packaging Process with an Advanced Packing and Palletizing Line"