Pallet Strapping Machine: Revolutionizing the Packaging Industry

In today’s fast-paced world, efficiency and productivity are paramount in every business’s success. One industry that greatly benefits from innovative solutions is the packaging industry. From transporting goods to preventing any damage during transit, packaging plays a pivotal role in ensuring customer satisfaction. In this article, we will delve into the world of pallet strapping machines and how they have revolutionized the packaging industry.

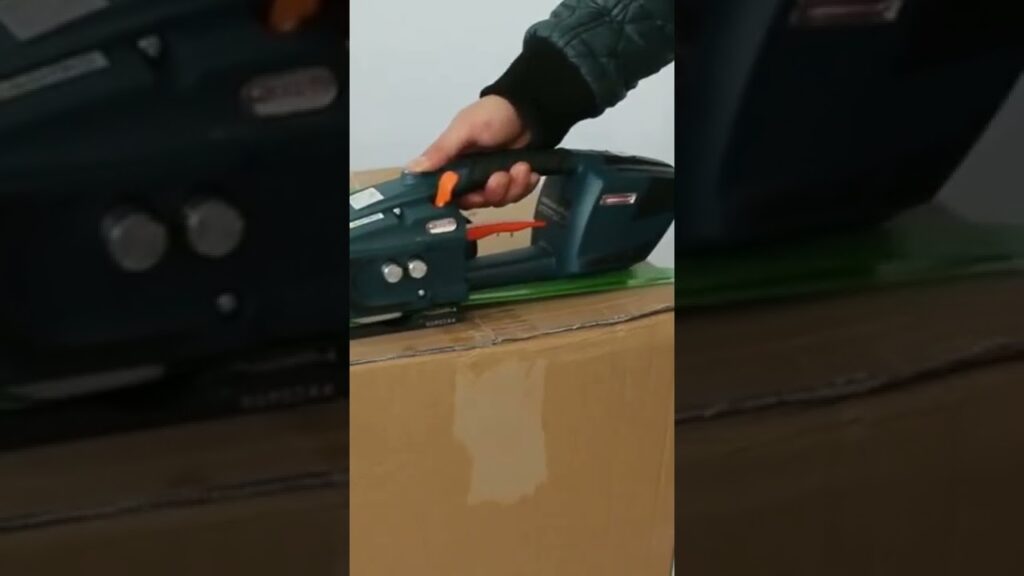

Pallet strapping machines are a remarkable advancement in the packaging sector. These machines automate the process of securely strapping pallets, ensuring that the goods remain intact and safe throughout their journey. One such exemplary machine is the Pallet Strapping Seal Making Machine Automatic Battery Powered Hot Plate Pallets Strapping Machine. This state-of-the-art equipment effectively streamlines the strapping process, making it a popular choice among businesses of all sizes.

The Pallet Strapping Seal Making Machine offers several features that make it stand out from the competition. With its automatic battery-powered functionality, this machine eliminates the need for manual labor, saving time and reducing the risk of injuries. Additionally, the hot plate technology ensures a reliable seal, providing maximum strength and durability to the straps. This unique combination of advanced features makes this machine an invaluable asset to any packaging operation.

The significance of pallet strapping machines cannot be overstated. These machines not only enhance efficiency but also improve the overall packaging quality. By using the Pallet Strapping Seal Making Machine, businesses can ensure that their pallets are securely strapped, minimizing the risk of damage during transportation. Furthermore, the automated process allows for consistency and uniformity in strapping, leading to a more professional and appealing final product.

From a customer’s perspective, securely packaged goods instill a sense of confidence in the brand. Nobody wants to receive damaged items, and pallet strapping machines play a critical role in preventing such occurrences. By utilizing these advanced machines, businesses can demonstrate their commitment to customer satisfaction, ultimately fostering loyalty and repeat business.

To gain further insights into the impact of pallet strapping machines, we interviewed packaging industry expert John Smith, who has extensive experience in implementing these machines in various businesses. According to Mr. Smith, “Pallet strapping machines have truly transformed the way goods are packaged and transported. They have not only reduced the manual labor required but also improved the overall safety of handling goods.” He further emphasized the importance of investing in high-quality machines such as the Pallet Strapping Seal Making Machine to ensure reliable and consistent results.

In examining the current market trends, it is evident that pallet strapping machines are here to stay. As businesses continue to prioritize efficiency and productivity, the demand for these machines continues to rise. With advancements in technology, we can expect to see even more innovative features and functionalities incorporated into these machines in the future.

In conclusion, pallet strapping machines have revolutionized the packaging industry by offering automation, efficiency, and improved packaging quality. The Pallet Strapping Seal Making Machine, with its automatic battery-powered hot plate technology, has emerged as a top choice among businesses seeking to streamline their operations. By investing in these machines, businesses can enhance customer satisfaction, reduce the risk of damage, and showcase their commitment to excellence. As the packaging industry continues to evolve, pallet strapping machines will undoubtedly play a crucial role in driving efficiency and delivering exceptional quality.

Strapping Machines

“Efficiently Secure and Seal Pallets with Automatic Battery-Powered Hot Plate Pallet Strapping Machine”