The palletizer is a crucial piece of machinery that plays an integral role in the packaging and palletizing process. With its ability to perform automatic palletizing operations on packaging bags, it streamlines production lines and increases efficiency. In this article, we will explore the Automatic Packing and Palletizing Line and discuss its significance in the packaging and palletizing production line.

In today’s fast-paced world, automation has become a necessity for businesses to stay competitive. The Automatic Packing and Palletizing Line is a prime example of how technology has revolutionized the packaging industry. By automating the palletizing process, companies can significantly reduce labor costs and minimize the risk of human error.

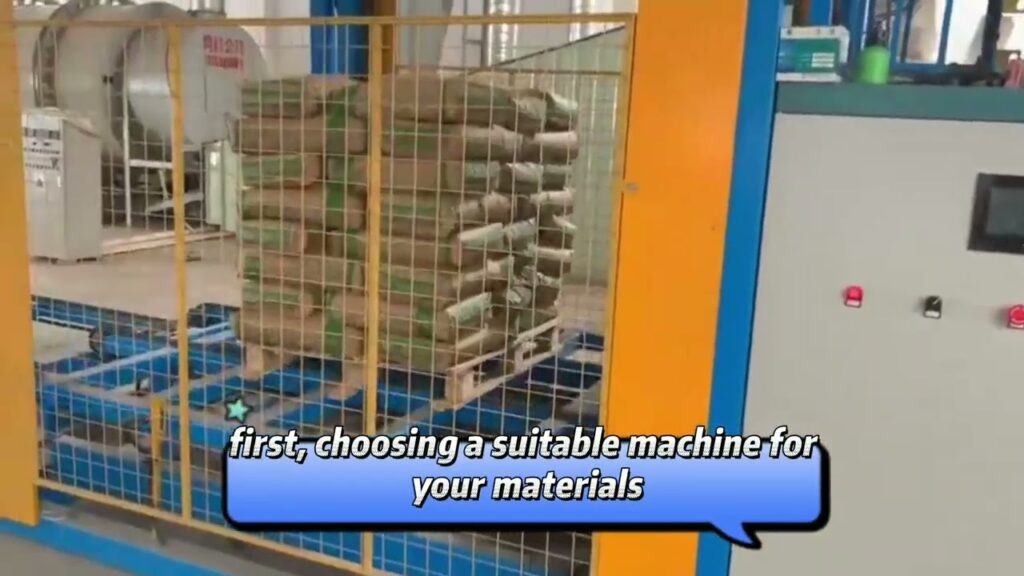

The heart of the Automatic Packing and Palletizing Line is the palletizer, a sophisticated machine that performs the task of stacking and arranging packaging bags onto pallets. This automated process ensures consistency and precision, allowing for optimal use of storage space and enhancing product safety during transportation.

One of the key benefits of the Automatic Packing and Palletizing Line is its ability to handle a wide range of packaging bag sizes and shapes. Whether it’s sacks, pouches, or cartons, the palletizer can adapt to different types of packaging, making it a versatile solution for various industries.

The Automatic Packing and Palletizing Line is equipped with advanced sensors and control systems that ensure the proper alignment and positioning of the packaging bags. This level of precision guarantees stable pallets and prevents any potential damage to the products, thus maintaining their quality.

Moreover, the Automatic Packing and Palletizing Line offers a high degree of flexibility. It can be seamlessly integrated into existing production lines, allowing companies to upgrade their packaging processes without disrupting the overall workflow. This flexibility is particularly advantageous for businesses that experience fluctuations in demand or wish to adapt to changing market trends.

By implementing the Automatic Packing and Palletizing Line, companies can also improve their operational efficiency. The palletizer can handle a large volume of packaging bags at a rapid pace, significantly increasing productivity. This, in turn, reduces bottlenecks in the production line and enables businesses to meet tight deadlines and customer demands more effectively.

In addition to its speed and efficiency, the Automatic Packing and Palletizing Line also prioritizes worker safety. By automating the palletizing process, companies can reduce the physical strain on employees, minimizing the risk of injuries associated with manual labor. This not only enhances worker well-being but also safeguards the company against potential liabilities and ensures regulatory compliance.

Furthermore, the Automatic Packing and Palletizing Line helps optimize space utilization in warehouses or storage facilities. The palletizer can stack the packaging bags in a compact manner, maximizing vertical space and allowing for efficient use of available storage areas. This is especially valuable for businesses that operate in limited spaces or have to deal with increasing stock volumes.

In conclusion, the Automatic Packing and Palletizing Line, with its advanced palletizer, is a game-changer in the packaging industry. Its ability to perform automatic palletizing operations on packaging bags enhances efficiency, reduces labor costs, and ensures product quality. By integrating this automated solution into their production lines, businesses can optimize their operations, improve worker safety, and adapt to changing market demands. The Automatic Packing and Palletizing Line is indeed a valuable asset for any company seeking to stay ahead in the competitive world of packaging and palletizing.

Automatic Packing Line

“Efficient Packaging and Palletizing of Products with an Advanced Production Line”