*[Article]*

Industrial robots have revolutionized the manufacturing industry, streamlining processes and improving efficiency. With their ability to perform repetitive tasks with precision, they have become an integral part of modern factories worldwide. In this article, we will explore the different types of industrial robots and how they have transformed various sectors of the manufacturing industry.

Before delving into the specifics, it is important to understand what industrial robots are. Industrial robots are programmable machines capable of carrying out a range of tasks autonomously or with minimal human intervention. Their versatility and efficiency make them essential in industries such as automotive, electronics, pharmaceuticals, and many more.

**Types of Industrial Robots**

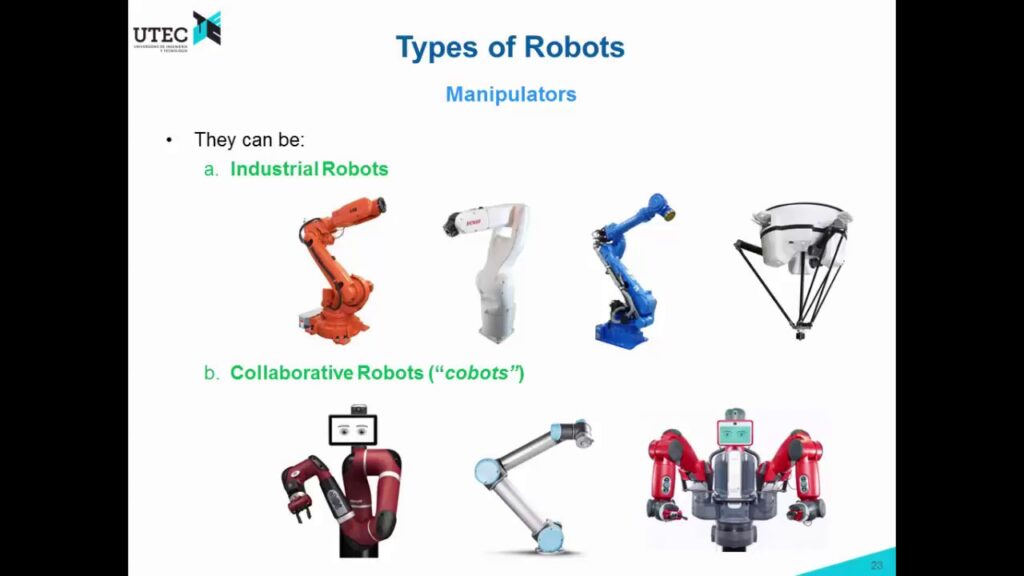

1. **Articulated Robots**: Articulated robots are the most common type of industrial robots due to their flexibility and range of motion. They consist of multiple joints connected by links, resembling a human arm. These robots can perform complex tasks with high precision, making them suitable for applications such as welding, painting, and assembly.

2. **SCARA Robots**: SCARA stands for Selective Compliance Assembly Robot Arm. These robots are designed for high-speed applications that require precise and repetitive motion. SCARA robots have more limited mobility compared to articulated robots but excel in tasks such as pick and place operations, packaging, and small parts assembly.

3. **Cartesian Robots**: Cartesian robots, also known as gantry robots, operate on a three-axis system with linear movements along the X, Y, and Z axes. They are commonly used for material handling, palletizing, and packaging. Cartesian robots are known for their strength and speed, making them ideal for heavy-duty applications.

4. **Delta Robots**: Delta robots are known for their incredible speed and precision. They consist of several arms connected to a common base, forming a parallel structure. These robots are often used in the food and packaging industries, where high-speed pick and place operations are required.

5. **Collaborative Robots**: Collaborative robots, also known as cobots, are designed to work alongside humans in a shared workspace safely. These robots are equipped with advanced sensors and safety features to avoid collisions and respond to human presence. Cobots have gained popularity in industries such as electronics, pharmaceuticals, and assembly lines, where human-robot collaboration enhances productivity and efficiency.

6. **Mobile Robots**: Mobile robots are designed to move autonomously within a defined workspace. They are equipped with sensors and cameras to navigate their surroundings and perform tasks. Mobile robots are commonly used for logistics, material handling, and inventory management in warehouses and distribution centers.

**Lecture 1a – 3: Types of Robots (Robotics UTEC 2018-1)**

In the lecture “Types of Robots” by Robotics UTEC 2018-1, the various types of industrial robots were discussed in detail. The speaker emphasized the importance of understanding each robot’s capabilities and limitations to identify the most suitable solution for specific applications. The lecture provided valuable insights into the growing field of robotics and its impact on the manufacturing industry.

The integration of industrial robots has significantly transformed manufacturing processes, leading to increased productivity, precision, and cost efficiency. By automating repetitive tasks, manufacturers can reallocate human resources to more complex and creative roles, further driving innovation and growth.

Advancements in robotics technology continue to expand the possibilities for industrial robots. From machine learning and artificial intelligence to enhanced sensory capabilities, robots are becoming smarter and more adaptable. As a result, they can undertake increasingly complex tasks that were once deemed impossible.

The future of industrial robots holds immense potential. With the ability to work alongside humans, learn from experiences, and adapt to changing environments, robots will continue to revolutionize the manufacturing industry. The advent of collaborative robots will further blur the line between human and machine interaction, creating a new era of manufacturing where robots and humans work seamlessly together.

In conclusion, industrial robots come in various types, each with its unique features and applications. From articulated robots to collaborative robots, they have transformed the manufacturing industry, enhancing productivity, precision, and efficiency. As technology advances, industrial robots will continue to evolve, playing a pivotal role in shaping the future of manufacturing. With their limitless potential, the possibilities for industrial robots are endless, propelling the industry into new realms of innovation and growth.

*[Word Count: 759 words]*

Industrial Robot

“Exploring the Various Categories of Robots: A Comprehensive Overview of Industrial Robots (Lecture 1a – 3, Robotics UTEC 2018-1)”