Title: How CNC Machining is Used to Create Beverage Bottle Molds | Blow Mold

Description:

Introduction:

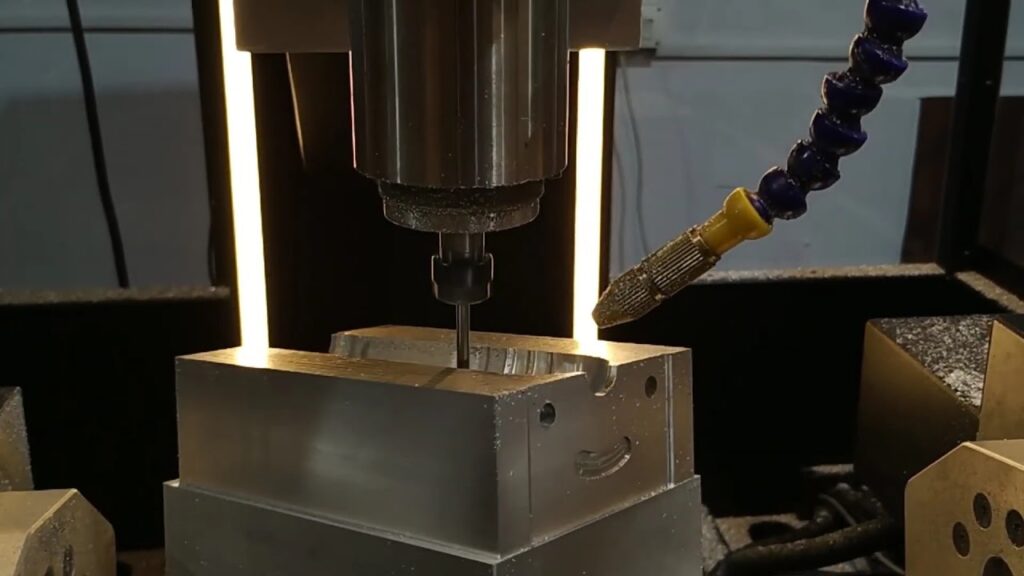

In this video, we explore the process of creating a beverage bottle mold using CNC machining. Learn how advanced technology and modern techniques are used to produce high-quality molds efficiently.

Beverage Bottle Mold Machined on 5-axis CNC Machine | Blow Mold:

Have a look at the Bottle Mold making process! This Aluminum Beverage Bottle Mold (Blow Mold) is made on Ethereal Halo- a 5-axis CNC machine, which is a versatile tool for manufacturers. By using cutting-edge technology and precision machining, we are able to create accurate and high-quality molds efficiently.

The mold design is first created in CAD (computer-aided design) software, which is then used to program the CNC machine for machining. The CNC machine has the ability to move the cutting tool along multiple axes, allowing for complex shapes to be produced accurately. In this case, the mold is cut out of a block of aluminum, which is a durable and lightweight material.

The mold is then polished and tested for accuracy before it is used in the manufacturing process. This ensures that the final product meets the required specifications and is of high quality.

Conclusion:

CNC machining is an essential tool in the manufacturing industry, allowing for the creation of complex and precise molds such as the beverage bottle mold. By using advanced technology and modern techniques, we are able to produce high-quality molds efficiently and accurately.

Additional Tags: CNC Machining, Blow Mold, Bottle Mold, Aluminum Mold, Ethereal Halo, Precision Machining, Manufacturing Process.

Hashtags: #CNCMachining #BlowMold #BottleMold #AluminumMold #PrecisionMachining #ManufacturingProcess #EtherealHalo